Tempering is a heat treatment process used to improve the hardness and toughness of metals, especially steel, by reheating quenched materials to a specific temperature below their critical point. This controlled reheating reduces brittleness while retaining strength and enhances the material's performance in practical applications. Discover how tempering can optimize your metalwork by exploring the full details in this article.

Table of Comparison

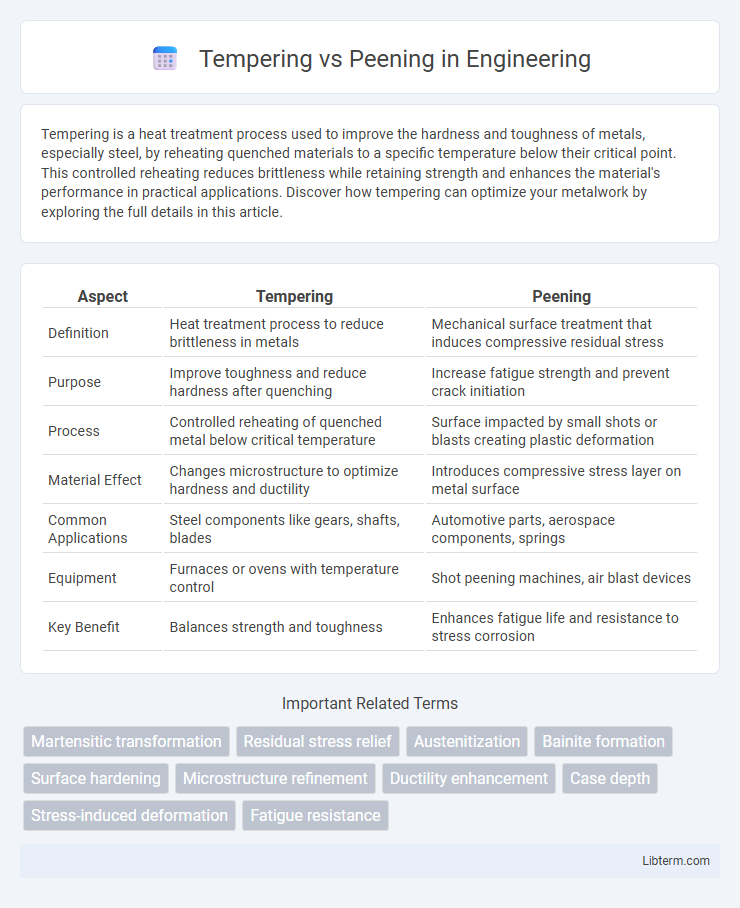

| Aspect | Tempering | Peening |

|---|---|---|

| Definition | Heat treatment process to reduce brittleness in metals | Mechanical surface treatment that induces compressive residual stress |

| Purpose | Improve toughness and reduce hardness after quenching | Increase fatigue strength and prevent crack initiation |

| Process | Controlled reheating of quenched metal below critical temperature | Surface impacted by small shots or blasts creating plastic deformation |

| Material Effect | Changes microstructure to optimize hardness and ductility | Introduces compressive stress layer on metal surface |

| Common Applications | Steel components like gears, shafts, blades | Automotive parts, aerospace components, springs |

| Equipment | Furnaces or ovens with temperature control | Shot peening machines, air blast devices |

| Key Benefit | Balances strength and toughness | Enhances fatigue life and resistance to stress corrosion |

Introduction to Tempering and Peening

Tempering is a heat treatment process used to improve the hardness and toughness of metals, primarily steel, by heating it to a specific temperature and then cooling it slowly. Peening involves mechanically working the surface of a metal, such as with shot peening or hammer peening, to enhance fatigue strength and reduce stress concentrations through induced compressive residual stresses. Both techniques play critical roles in improving the mechanical properties and durability of metal components in various industrial applications.

Defining Tempering: Purpose and Process

Tempering is a heat treatment process used to improve the toughness and reduce the brittleness of hardened steel by reheating it to a specific temperature below its critical point, then allowing it to cool slowly. This controlled reheating alters the microstructure, relieving internal stresses and enhancing mechanical properties such as ductility and impact resistance. Unlike peening, which involves mechanical deformation to induce compressive stresses, tempering focuses on thermal modification to balance hardness and strength in metal components.

Understanding Peening: Techniques and Benefits

Peening involves mechanically impacting a material's surface using methods such as shot peening, laser peening, or ultrasonic peening to induce compressive residual stresses. These techniques enhance fatigue resistance, reduce stress corrosion cracking, and improve overall durability by modifying the microstructure of metals. Unlike tempering, which relies on controlled heating and cooling to adjust hardness and toughness, peening primarily strengthens surfaces through mechanical deformation without altering the bulk material properties.

Key Differences Between Tempering and Peening

Tempering is a heat treatment process that alters the microstructure of hardened steel to enhance toughness and reduce brittleness by heating it to a specific temperature below the critical point, followed by controlled cooling. Peening, on the other hand, is a mechanical surface treatment involving repeated impact or shot blasting to induce compressive residual stresses, which improve fatigue resistance and prevent crack initiation. While tempering modifies the internal properties of the metal through thermal means, peening primarily strengthens the surface layer via mechanical deformation.

Metallurgical Impacts of Tempering

Tempering significantly improves the toughness and ductility of steel by relieving internal stresses and reducing brittleness caused by quenching. This heat treatment process modifies the steel's microstructure, transforming martensite into tempered martensite or bainite, which enhances mechanical properties and fatigue resistance. In contrast, peening primarily induces compressive residual stresses on the surface to improve fatigue life without altering the bulk microstructure.

Effects of Peening on Material Properties

Peening improves fatigue strength and resistance to stress corrosion cracking by introducing compressive residual stresses on the material surface. This process enhances hardness and surface durability without affecting the core properties. Unlike tempering, which reduces hardness and relieves internal stresses through heating, peening strengthens the outer layer through mechanical deformation.

Applications of Tempering in Industry

Tempering is widely used in the automotive and aerospace industries to enhance the toughness and reduce the brittleness of steel components such as gears, crankshafts, and aircraft landing gear. It improves the mechanical properties of tool steels and cutting instruments, ensuring better performance and longer service life under high-stress conditions. The process also finds critical applications in manufacturing structural parts for construction and heavy machinery, where durability and resistance to impact are essential.

Industrial Uses for Peening

Peening is extensively used in industrial applications to enhance the fatigue resistance of metal components by inducing compressive residual stresses on their surfaces, thereby preventing crack initiation and propagation. Unlike tempering, which primarily adjusts the hardness and toughness of the metal through controlled heating and cooling, peening methods such as shot peening or laser peening directly improve surface durability and extend the lifespan of parts subjected to cyclic loading. Industries including aerospace, automotive, and heavy machinery rely on peening to strengthen critical elements such as turbine blades, gears, and suspension components, ensuring superior performance under demanding operational conditions.

Choosing Between Tempering and Peening

Choosing between tempering and peening depends on the material properties and desired mechanical performance; tempering enhances toughness and reduces brittleness in hardened steels by controlled reheating, while peening induces compressive surface stresses to improve fatigue resistance and prevent crack initiation. Tempering is optimal for applications requiring balanced strength and ductility, whereas peening is preferred when surface durability under cyclic loads is critical. Understanding the operational environment and load conditions guides the most effective heat treatment or surface modification technique.

Conclusion: Optimizing Material Performance

Tempering enhances material toughness and reduces brittleness by controlled reheating and cooling, while peening improves surface strength and fatigue resistance through mechanical impact. Optimizing material performance involves selecting tempering for internal stress relief and ductility, and peening for surface hardening and crack prevention. Combining both processes tailors mechanical properties for demanding engineering applications, ensuring durability and reliability.

Tempering Infographic

libterm.com

libterm.com