Flexible manufacturing systems adapt quickly to changes in production demands, enabling efficient handling of varied product types with minimal downtime. This approach enhances operational agility, reduces costs, and improves responsiveness to market fluctuations. Discover how flexible manufacturing can transform your production process by reading the full article.

Table of Comparison

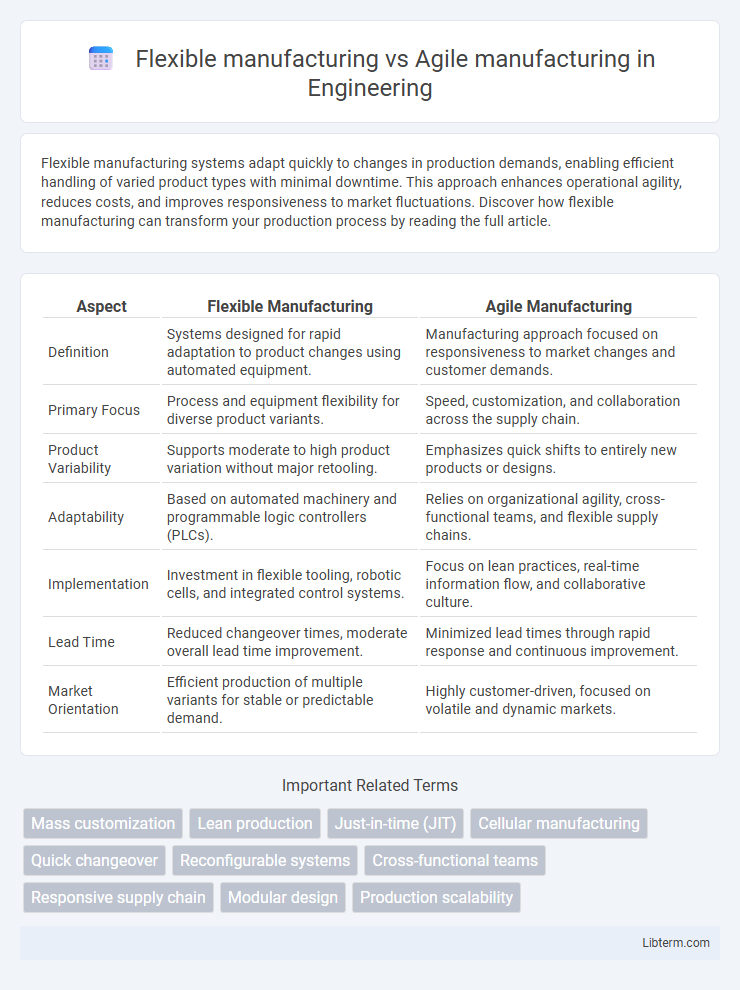

| Aspect | Flexible Manufacturing | Agile Manufacturing |

|---|---|---|

| Definition | Systems designed for rapid adaptation to product changes using automated equipment. | Manufacturing approach focused on responsiveness to market changes and customer demands. |

| Primary Focus | Process and equipment flexibility for diverse product variants. | Speed, customization, and collaboration across the supply chain. |

| Product Variability | Supports moderate to high product variation without major retooling. | Emphasizes quick shifts to entirely new products or designs. |

| Adaptability | Based on automated machinery and programmable logic controllers (PLCs). | Relies on organizational agility, cross-functional teams, and flexible supply chains. |

| Implementation | Investment in flexible tooling, robotic cells, and integrated control systems. | Focus on lean practices, real-time information flow, and collaborative culture. |

| Lead Time | Reduced changeover times, moderate overall lead time improvement. | Minimized lead times through rapid response and continuous improvement. |

| Market Orientation | Efficient production of multiple variants for stable or predictable demand. | Highly customer-driven, focused on volatile and dynamic markets. |

Understanding Flexible Manufacturing

Flexible manufacturing systems (FMS) are designed to easily adapt to changes in product type and volume through automated machinery and programmable equipment, enhancing production efficiency and minimizing downtime. These systems emphasize rapid switchovers and scalable operations, allowing manufacturers to handle a variety of products with minimal reconfiguration. Understanding flexible manufacturing involves recognizing its capacity to respond swiftly to market demands while maintaining consistent quality and cost control.

Defining Agile Manufacturing

Agile manufacturing emphasizes rapid responsiveness to customer demands and changing market conditions through cross-functional teams and flexible processes, prioritizing speed and adaptability over rigid efficiency. It leverages real-time data integration and collaborative technologies to enable swift decision-making and customization. Unlike flexible manufacturing, which focuses on the ability to produce a variety of products with minimal retooling, agile manufacturing fosters continuous innovation and fast product development cycles.

Core Principles of Flexibility

Flexible manufacturing centers on adaptability in equipment and processes to handle diverse product types and volumes efficiently, emphasizing modular machinery and quick changeovers. Agile manufacturing prioritizes rapid responsiveness to market changes and customer demands through integrated communication systems and collaborative teams. Core principles of flexibility include scalable production capacity, process reconfigurability, and real-time data utilization for decision-making.

Agility: Key Characteristics

Agile manufacturing emphasizes rapid responsiveness to market changes through modular processes, cross-functional teams, and real-time data integration, enabling swift adaptation to customer demands. It prioritizes collaboration and continuous improvement to reduce lead times and enhance product customization. Unlike flexible manufacturing, agility centers on speed and customer-centric innovation to maintain competitive advantage in dynamic environments.

Technology in Flexible Manufacturing

Flexible manufacturing employs advanced automation technologies such as CNC machines, robotics, and integrated computer systems to enable quick adaptation to product variations without significant downtime. It uses real-time data analytics and IoT sensors to monitor equipment performance and optimize production processes dynamically. These technologies collectively enhance scalability and responsiveness, making flexible manufacturing ideal for diverse, low-volume product runs.

Digital Transformation in Agile Manufacturing

Agile manufacturing leverages digital transformation through real-time data analytics, IoT integration, and AI-driven decision-making to rapidly adapt production processes to changing market demands. Unlike flexible manufacturing, which emphasizes equipment versatility and reconfigurability, agile manufacturing prioritizes responsiveness and innovation speed enabled by digital technologies. The implementation of cloud computing and digital twins in agile manufacturing enhances collaboration, reduces lead times, and drives continuous improvement across the supply chain.

Comparing Response to Market Changes

Flexible manufacturing systems quickly retool equipment and shift production lines to accommodate product variations, minimizing downtime and maintaining steady output during market fluctuations. Agile manufacturing emphasizes rapid decision-making, collaboration, and real-time data integration to swiftly respond to unpredictable demand shifts and evolving customer preferences. While flexible manufacturing focuses on physical adaptability, agile manufacturing combines operational flexibility with strategic responsiveness to optimize market change reactions.

Benefits and Limitations of Flexible Manufacturing

Flexible manufacturing enhances production efficiency by enabling quick adaptation to varying product specifications and volumes, reducing downtime and tooling costs. Its primary benefits include versatility in handling multiple product types and scalability, while limitations involve higher initial investment and complexity in system setup. Compared to agile manufacturing, flexible manufacturing may lack the speed and responsiveness required for rapid market changes despite its operational adaptability.

Strengths and Challenges of Agile Manufacturing

Agile manufacturing excels in rapid responsiveness to market changes and customer demands, driven by advanced technology integration and collaborative processes, enhancing innovation and time-to-market efficiency. Its strength lies in adaptability to diverse product variants and small batch sizes, but challenges include high initial investment, the need for skilled workforce, and complexity in managing dynamic supply chains. Unlike flexible manufacturing, which emphasizes equipment versatility, agile manufacturing focuses on organizational agility and cross-functional teamwork to achieve competitive advantage.

Choosing Between Flexible and Agile Manufacturing

Choosing between flexible manufacturing and agile manufacturing depends on production goals: flexible manufacturing excels in handling varied product types with minimal changeover time, ideal for customization and medium-to-high volume batches. Agile manufacturing thrives in rapid response to market changes, emphasizing speed, adaptability, and collaboration to meet fluctuating customer demands in low-to-medium volume environments. Evaluating factors like product variety, lead time requirements, and market volatility helps determine which approach maximizes operational efficiency and competitiveness.

Flexible manufacturing Infographic

libterm.com

libterm.com