Acme Thread is a specialized type of trapezoidal thread designed for power transmission and linear motion applications, offering high strength and durability compared to standard threads. Its unique geometry provides reduced friction and increased load-carrying capacity, making it ideal for machine tool leadscrews and other precision devices. Explore the rest of this article to discover how Acme Threads can enhance your mechanical designs and improve performance.

Table of Comparison

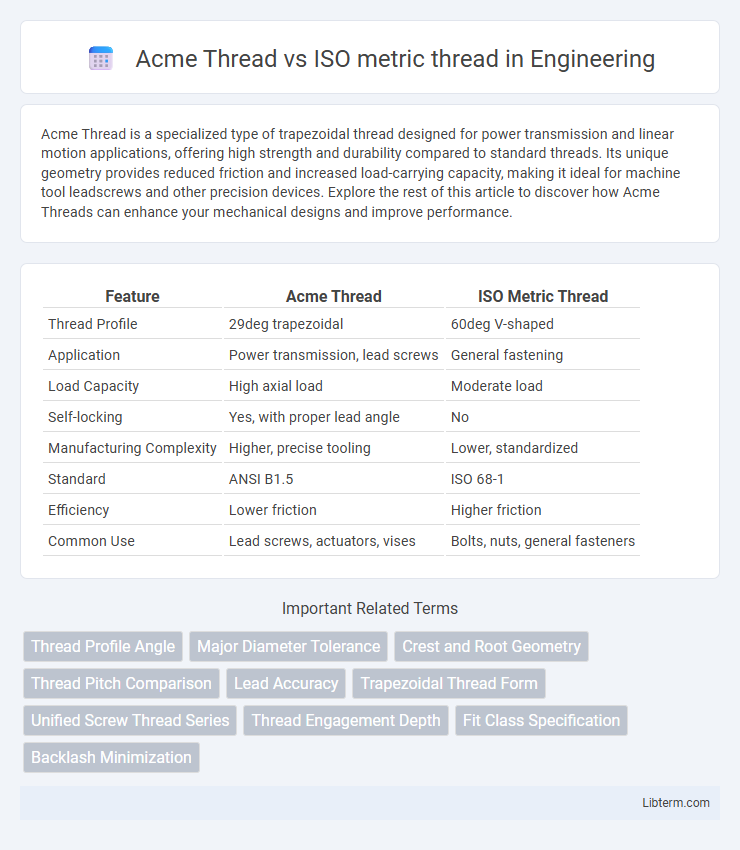

| Feature | Acme Thread | ISO Metric Thread |

|---|---|---|

| Thread Profile | 29deg trapezoidal | 60deg V-shaped |

| Application | Power transmission, lead screws | General fastening |

| Load Capacity | High axial load | Moderate load |

| Self-locking | Yes, with proper lead angle | No |

| Manufacturing Complexity | Higher, precise tooling | Lower, standardized |

| Standard | ANSI B1.5 | ISO 68-1 |

| Efficiency | Lower friction | Higher friction |

| Common Use | Lead screws, actuators, vises | Bolts, nuts, general fasteners |

Introduction to Acme Thread and ISO Metric Thread

Acme threads feature a trapezoidal profile with a 29-degree angle, designed for power transmission and heavy loads, commonly used in lead screws and industrial machinery. ISO metric threads have a 60-degree triangular profile standardized by the International Organization for Standardization, primarily used for fastening applications in mechanical engineering worldwide. Both thread types optimize strength and efficiency but serve distinct roles in mechanical design due to their geometric differences and application-specific performance.

Historical Development of Thread Standards

Acme threads, developed in the late 19th century, were designed to improve load capacity and durability in power transmission applications, replacing the square thread with a more robust trapezoidal profile. ISO metric threads emerged in the mid-20th century as part of the International Organization for Standardization's efforts to unify thread standards for global compatibility and interchangeability. The historical development of these thread standards reflects the transition from specialized industrial designs to universally accepted specifications facilitating worldwide engineering collaboration.

Design and Geometry Differences

Acme threads feature a trapezoidal profile with a 29-degree thread angle, designed for high-load applications and efficient power transmission, while ISO metric threads have a symmetrical V-shaped profile with a 60-degree thread angle optimized for general fastening purposes. Acme threads have flat crests and roots, providing increased strength and reduced wear, whereas ISO metric threads have rounded crests and roots to minimize stress concentration. The distinct pitch, thread depth, and profile shapes between Acme and ISO metric threads influence their suitability for different mechanical functions and load conditions.

Material Compatibility and Strength

Acme threads, typically made from steel or stainless steel, offer superior strength and wear resistance ideal for heavy-duty applications requiring high load capacity. ISO metric threads, commonly produced in a wider range of materials including aluminum and plastics, provide versatility but generally exhibit lower strength compared to Acme threads. Material compatibility for Acme threads favors metals with high tensile strength, while ISO metric threads accommodate diverse materials suited for precision and light-to-medium load environments.

Applications in Industry

Acme threads are widely used in heavy machinery, linear actuators, and lead screws due to their strength and efficient load-carrying capacity, ideal for power transmission and motion control. ISO metric threads dominate in automotive, manufacturing, and aerospace industries because of their standardized dimensions, ease of mass production, and compatibility with metric fasteners. Both thread types address specific industrial needs: Acme for high-load mechanical systems and ISO metric for precision fastening and assembly.

Advantages of Acme Threads

Acme threads offer superior load-carrying capacity and better wear resistance compared to ISO metric threads, making them ideal for heavy-duty applications such as lead screws in machinery. Their trapezoidal profile provides smoother engagement and reduced backlash, enhancing precision and operational efficiency. The wider thread angles also facilitate easier manufacturing and maintenance, contributing to longer service life in industrial settings.

Benefits of ISO Metric Threads

ISO Metric Threads offer superior standardization, ensuring global compatibility across various manufacturing and engineering applications. Their symmetrical V-shaped profile provides enhanced strength and ease of assembly compared to the trapezoidal profile of Acme Threads. This thread type supports higher precision and better load distribution, promoting durability and reliable performance in high-speed and high-torque environments.

Limitations and Challenges

Acme threads face challenges in high-precision applications due to their trapezoidal profile causing increased friction and lower efficiency compared to ISO metric threads, which have a symmetrical V-profile optimized for strength and precision. Limitations of Acme threads include greater backlash and wear in automated systems, while ISO metric threads offer tighter tolerances and better suitability for fasteners requiring consistent torque and load distribution. Acme threads are typically less compatible with modern CNC machining standards, whereas ISO metric threads benefit from widespread international standardization, facilitating easier part interchangeability and quality control.

Selection Criteria for Engineers

Engineers selecting between Acme Thread and ISO metric thread prioritize application requirements such as load capacity, strength, and precision. Acme threads excel in power transmission and robustness, making them ideal for heavy machinery and linear motion, while ISO metric threads provide standardized dimensions suitable for general mechanical fastening with higher precision. Considerations include thread geometry, load type, and compatibility with existing components to ensure optimal performance and durability in the intended engineering application.

Future Trends in Thread Standards

The Acme thread, known for its trapezoidal profile and high load-bearing capacity, is increasingly integrated with smart manufacturing systems to enhance precision in linear motion applications, while ISO metric threads benefit from global standardization driving uniformity in mechanical assemblies. Future trends indicate a convergence towards hybrid thread standards combining Acme's strength with ISO's modularity, leveraging additive manufacturing capabilities and advanced materials for greater durability. Emerging Industry 4.0 technologies and IoT connectivity are pushing thread standards to evolve with embedded sensors and real-time performance monitoring to optimize maintenance and lifespan.

Acme Thread Infographic

libterm.com

libterm.com