Tangential flow filtration (TFF) is a highly efficient separation technique used to concentrate and purify biomolecules by directing the fluid tangentially across the surface of a membrane. This process minimizes membrane fouling and ensures higher yield and productivity in bioprocessing applications. Discover how tangential flow can optimize Your filtration requirements by exploring the detailed benefits and applications described in the rest of this article.

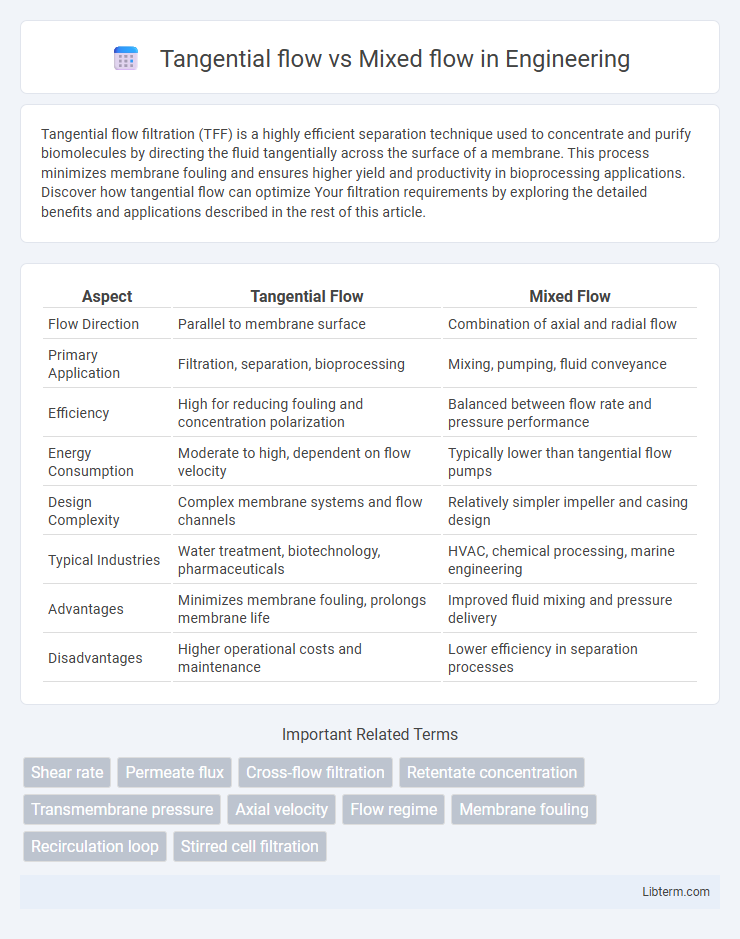

Table of Comparison

| Aspect | Tangential Flow | Mixed Flow |

|---|---|---|

| Flow Direction | Parallel to membrane surface | Combination of axial and radial flow |

| Primary Application | Filtration, separation, bioprocessing | Mixing, pumping, fluid conveyance |

| Efficiency | High for reducing fouling and concentration polarization | Balanced between flow rate and pressure performance |

| Energy Consumption | Moderate to high, dependent on flow velocity | Typically lower than tangential flow pumps |

| Design Complexity | Complex membrane systems and flow channels | Relatively simpler impeller and casing design |

| Typical Industries | Water treatment, biotechnology, pharmaceuticals | HVAC, chemical processing, marine engineering |

| Advantages | Minimizes membrane fouling, prolongs membrane life | Improved fluid mixing and pressure delivery |

| Disadvantages | Higher operational costs and maintenance | Lower efficiency in separation processes |

Introduction to Fluid Dynamics in Filtration

Tangential flow filtration (TFF) directs fluid parallel to the membrane surface, minimizing fouling by continuously sweeping away retained particles, enhancing filtration efficiency in bioprocessing applications. Mixed flow filtration combines both tangential and perpendicular flow components, fostering better mixing and reducing concentration polarization, which improves separation performance in complex fluid systems. Understanding these flow dynamics is critical for optimizing membrane filtration processes in biotechnology and water treatment.

Overview of Tangential Flow Filtration

Tangential Flow Filtration (TFF) is a membrane filtration process where the feed stream flows parallel to the membrane surface, reducing fouling and allowing continuous filtration of large volumes. It efficiently separates and concentrates biomolecules, cells, and particulates by maintaining a steady crossflow velocity that enhances solute retention and permeate flux. TFF is widely used in biotechnology and pharmaceutical industries for protein purification, cell harvesting, and buffer exchange, offering scalability and gentle processing conditions.

Understanding Mixed Flow Filtration

Mixed flow filtration combines the principles of tangential flow and dead-end filtration, enhancing filtration efficiency by promoting both crossflow and depth filtration mechanisms. This process reduces membrane fouling and increases permeate flux, making it ideal for complex liquid streams with high particulate loads. Understanding mixed flow filtration is essential for optimizing separation performance in bioprocessing and wastewater treatment applications.

Key Differences Between Tangential and Mixed Flow

Tangential flow features fluid moving parallel to the membrane surface, minimizing fouling and allowing high filtration efficiency in bioprocessing and water treatment. Mixed flow involves turbulent fluid movement throughout the volume, promoting uniform distribution and enhancing mixing but with higher energy consumption. Key differences include flow direction relative to the membrane, fouling control efficacy, and energy usage, impacting their suitability for filtration and mixing applications.

Efficiency and Performance Comparison

Tangential flow pumps offer higher efficiency in handling viscous fluids due to their ability to maintain consistent flow rates with minimal shear stress, enhancing performance in filtration and separation applications. Mixed flow pumps combine features of axial and radial designs, delivering higher flow rates with moderate pressure, making them suitable for applications requiring balanced efficiency and elevated throughput. Comparing both, tangential flow pumps excel in energy savings and long-term operational stability, while mixed flow pumps provide superior performance in volume-driven scenarios requiring moderate efficiency.

Applications of Tangential Flow Systems

Tangential flow filtration (TFF) systems are widely used in bioprocessing applications such as protein concentration, cell harvest, and diafiltration due to their ability to minimize membrane fouling and maintain high filtration efficiency. Unlike mixed flow systems, TFF enables continuous removal of permeate while retaining valuable biomolecules, making it ideal for pharmaceutical manufacturing and vaccine production. These systems excel in scaling up from research to industrial levels, providing consistent product quality and operational control.

Industrial Uses of Mixed Flow Filtration

Mixed flow filtration is widely employed in industrial applications requiring efficient separation of particles in liquid streams, such as wastewater treatment, chemical processing, and pharmaceutical manufacturing. Its design combines axial and radial flow patterns, enhancing filtration capacity and reducing fouling compared to tangential flow systems. Industries benefit from mixed flow filtration due to its ability to handle high solids content and maintain consistent performance in large-scale operations.

Advantages and Disadvantages of Each Method

Tangential flow filtration offers high efficiency in separating particles with minimal membrane fouling due to its parallel flow, making it advantageous for high-concentration samples but can be limited by slower processing speeds. Mixed flow filtration combines axial and radial flow patterns, providing superior shear rate control and increased permeate flux, which benefits the processing of viscous liquids but may lead to higher energy consumption and system complexity. The choice between tangential flow and mixed flow depends on balancing operational costs, membrane lifespan, and desired throughput in industrial or bioprocessing applications.

Factors Influencing System Selection

Factors influencing the selection between tangential flow and mixed flow systems include fluid viscosity, particle size distribution, and desired separation efficiency. Tangential flow excels in handling high-solids content and minimizing membrane fouling due to its cross-flow dynamics, making it suitable for processes requiring gentle filtration. Mixed flow systems offer improved mixing and turbulence, benefiting applications with low-viscosity fluids or where enhanced mass transfer rates and uniform suspension are critical.

Future Trends in Filtration Technologies

Tangential flow filtration (TFF) and mixed flow filtration both aim to enhance separation efficiency, yet future trends emphasize integrating advanced membrane materials and automated process controls to overcome fouling and improve throughput. Innovations in nanomaterials and smart membranes are projected to boost selectivity and durability in both TFF and mixed flow systems, facilitating applications in biopharmaceutical and wastewater treatment. The convergence of real-time monitoring with AI-driven optimization is expected to revolutionize filtration technology, minimizing energy consumption and operational costs while maximizing product purity.

Tangential flow Infographic

libterm.com

libterm.com