An intercooler enhances engine performance by cooling the compressed air from the turbocharger, increasing air density for better combustion and power output. Efficient intercoolers reduce engine temperatures, preventing knocking and improving reliability during high-performance driving. Explore the article to learn how your vehicle's intercooler optimizes power and efficiency.

Table of Comparison

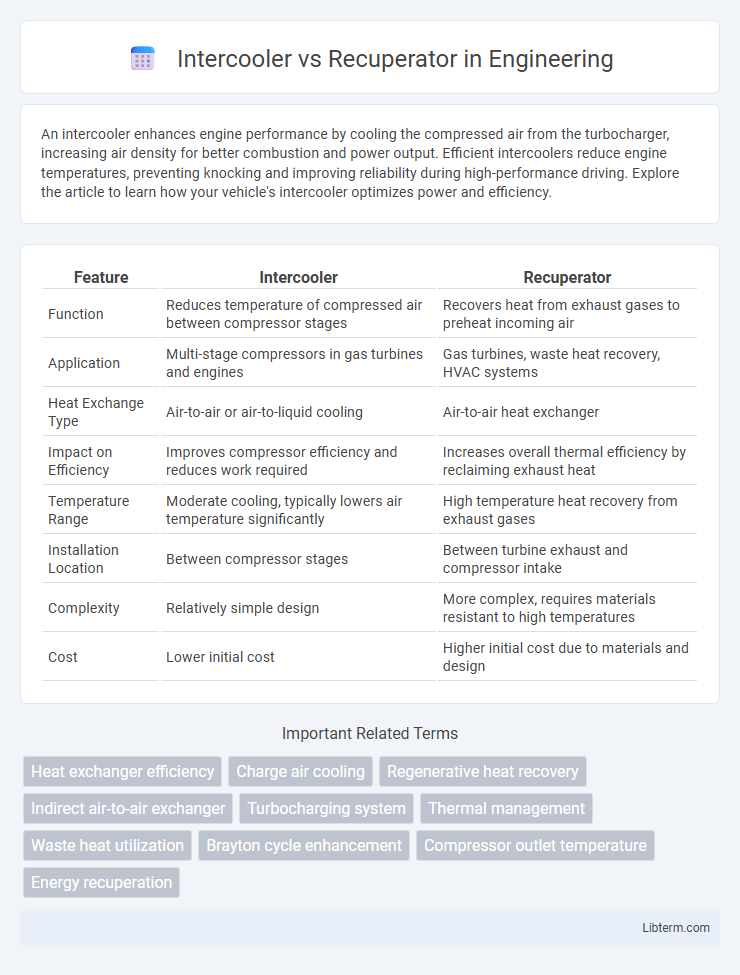

| Feature | Intercooler | Recuperator |

|---|---|---|

| Function | Reduces temperature of compressed air between compressor stages | Recovers heat from exhaust gases to preheat incoming air |

| Application | Multi-stage compressors in gas turbines and engines | Gas turbines, waste heat recovery, HVAC systems |

| Heat Exchange Type | Air-to-air or air-to-liquid cooling | Air-to-air heat exchanger |

| Impact on Efficiency | Improves compressor efficiency and reduces work required | Increases overall thermal efficiency by reclaiming exhaust heat |

| Temperature Range | Moderate cooling, typically lowers air temperature significantly | High temperature heat recovery from exhaust gases |

| Installation Location | Between compressor stages | Between turbine exhaust and compressor intake |

| Complexity | Relatively simple design | More complex, requires materials resistant to high temperatures |

| Cost | Lower initial cost | Higher initial cost due to materials and design |

Introduction to Intercoolers and Recuperators

Intercoolers and recuperators are essential heat exchange devices used to improve energy efficiency in various industrial processes. Intercoolers primarily cool compressed air between compression stages in gas turbines or compressors, reducing temperature and increasing density for better performance. Recuperators recover waste heat from exhaust gases to preheat incoming air, enhancing thermal efficiency in systems like gas turbines and furnaces.

Key Differences Between Intercoolers and Recuperators

Intercoolers and recuperators differ primarily in their functions and applications: intercoolers are heat exchangers designed to cool compressed air between stages of compression, improving engine efficiency and performance, while recuperators recover waste heat from exhaust gases to preheat incoming air or fluids, enhancing overall thermal efficiency. Intercoolers typically operate with air-to-air or air-to-liquid heat exchange systems focused on cooling, whereas recuperators often use air-to-air or air-to-fuel heat exchange to reclaim energy. The materials and designs also vary, with intercoolers prioritizing rapid heat dissipation and low pressure drop, and recuperators engineered for high-temperature endurance and maximum heat recovery.

How Intercoolers Work: Principles and Applications

Intercoolers function by cooling compressed air between stages of a multi-stage compressor, utilizing heat exchange principles to remove heat from the air and enhance engine efficiency. This temperature reduction increases air density, allowing more oxygen into the combustion chamber, which improves performance and reduces the risk of engine knocking. Intercoolers are commonly applied in turbocharged and supercharged engines to maximize power output and fuel economy by maintaining optimal intake air temperatures.

Recuperators: Functionality and Use Cases

Recuperators are heat exchangers designed to recover waste heat from exhaust gases and transfer it to incoming air, significantly enhancing energy efficiency in industrial processes. They are commonly used in furnaces, gas turbines, and HVAC systems to reduce fuel consumption and lower emissions by preheating combustion air. Unlike intercoolers, which primarily cool compressed air between compressor stages, recuperators focus on reclaiming thermal energy, making them ideal for high-temperature applications requiring heat recovery.

Thermal Efficiency: Intercooler vs Recuperator

Intercoolers and recuperators both enhance thermal efficiency by recovering or managing heat in thermodynamic cycles. Intercoolers improve efficiency by cooling compressed air between stages, reducing work input and increasing mass flow density, which enhances power output in gas turbines. Recuperators boost thermal efficiency by transferring waste heat from exhaust gases to the compressed air before combustion, decreasing fuel consumption and raising overall cycle efficiency in systems like microturbines and combined heat and power plants.

Impact on Engine Performance and Fuel Economy

An intercooler reduces the temperature of compressed air from the turbocharger, increasing air density and improving engine performance by enhancing combustion efficiency and power output. A recuperator transfers heat from exhaust gases to the intake air, improving fuel economy by recovering waste heat and reducing fuel consumption in thermal engines. While intercoolers primarily boost engine power, recuperators emphasize fuel efficiency through waste heat recovery, making each component crucial depending on the engine design and performance goals.

Suitability for Various Industries and Systems

Intercoolers function efficiently in gas compression industries such as HVAC, automotive, and refrigeration by reducing air temperature between compressor stages, enhancing system performance and energy efficiency. Recuperators are ideal for high-temperature applications like power plants, steel manufacturing, and furnace systems, where they transfer heat from exhaust gases to incoming air, improving thermal efficiency and reducing fuel consumption. Selection depends on operating temperature ranges, system design, and desired energy savings, with intercoolers suited for moderate temperature control and recuperators optimized for high-temperature heat recovery.

Advantages and Limitations of Intercoolers

Intercoolers enhance engine efficiency by cooling the compressed air between stages, resulting in higher air density and improved combustion performance. They are advantageous due to their relatively simple design, cost-effectiveness, and ability to reduce engine operating temperatures, which prolongs component life. However, intercoolers are limited by pressure drop issues and less heat recovery compared to recuperators, which recycle exhaust heat for energy savings.

Pros and Cons of Recuperators

Recuperators offer high energy efficiency by transferring heat from exhaust gases to incoming air or fuel, reducing fuel consumption and operating costs. They typically have lower pressure drops compared to intercoolers, which enhances system performance but may require frequent maintenance to prevent fouling and maintain heat transfer efficiency. A notable downside includes susceptibility to high-temperature corrosion and damage from particulates, limiting their use in harsh environments compared to intercoolers.

Choosing the Right Technology for Your Needs

Intercoolers and recuperators both enhance thermal efficiency in heat exchange systems but serve different purposes: intercoolers cool compressed air between stages to reduce work, while recuperators recover waste heat from exhaust gases to preheat incoming air. Choosing the right technology depends on factors like operating temperature, pressure levels, and the specific energy savings targeted; intercoolers are often preferred in multi-stage compressors, whereas recuperators excel in high-temperature exhaust applications. Evaluating system design constraints, maintenance costs, and performance goals ensures optimal integration of either intercooling or heat recovery technologies.

Intercooler Infographic

libterm.com

libterm.com