Lead time refers to the total duration from the initiation of a process until its completion, crucial for efficient project and supply chain management. Understanding lead time helps optimize production schedules, minimize delays, and enhance customer satisfaction by ensuring timely deliveries. Discover how mastering lead time can improve Your operations by reading the rest of the article.

Table of Comparison

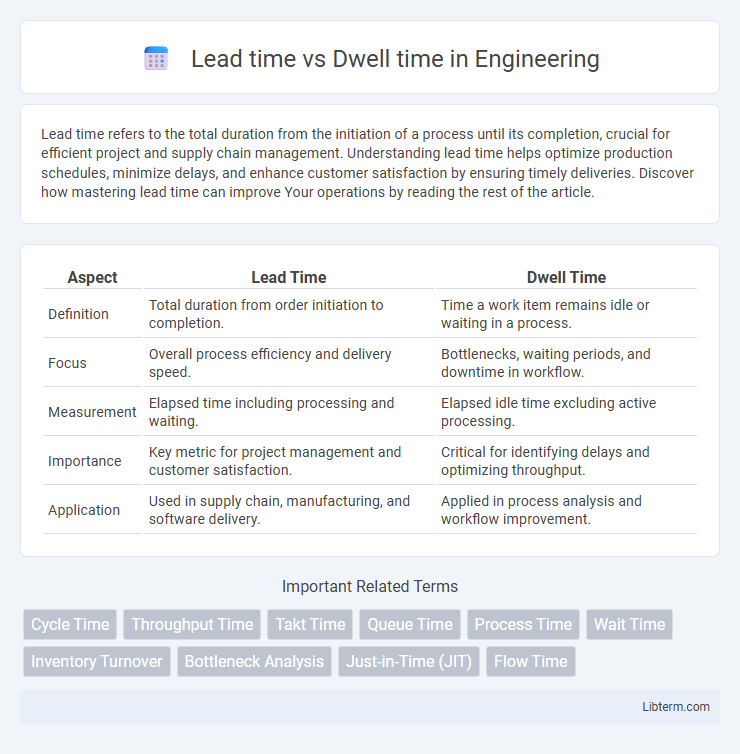

| Aspect | Lead Time | Dwell Time |

|---|---|---|

| Definition | Total duration from order initiation to completion. | Time a work item remains idle or waiting in a process. |

| Focus | Overall process efficiency and delivery speed. | Bottlenecks, waiting periods, and downtime in workflow. |

| Measurement | Elapsed time including processing and waiting. | Elapsed idle time excluding active processing. |

| Importance | Key metric for project management and customer satisfaction. | Critical for identifying delays and optimizing throughput. |

| Application | Used in supply chain, manufacturing, and software delivery. | Applied in process analysis and workflow improvement. |

Introduction to Lead Time and Dwell Time

Lead time refers to the total duration from the initiation of a process until its completion, often used in manufacturing and supply chain contexts to measure efficiency. Dwell time specifically measures the period an item or shipment remains at a particular location or stage within the process, such as warehouse storage or transit points. Understanding the distinction between lead time and dwell time is crucial for optimizing operational workflows and reducing delays.

Defining Lead Time: Meaning and Importance

Lead time refers to the total duration from the initiation of a process or order to its completion or delivery, serving as a critical metric in supply chain management and manufacturing. It impacts customer satisfaction and operational efficiency by determining how quickly products or services are delivered. Understanding lead time helps businesses optimize production schedules, reduce inventory costs, and improve responsiveness to market demand.

Understanding Dwell Time: Key Concepts

Dwell time measures the duration a customer spends engaging with content, such as a webpage or ad, before taking action or leaving, reflecting the quality of their interaction. Higher dwell time indicates stronger user interest and better content relevance, which can improve search engine rankings and conversion rates. Understanding dwell time helps marketers optimize user experience, enhance engagement strategies, and reduce bounce rates effectively.

Lead Time vs Dwell Time: Core Differences

Lead time measures the total duration from the initiation of a process to its completion, while dwell time specifically tracks the period an item or individual remains in a particular state or location during that process. Lead time encompasses all phases, including processing, waiting, and transit, whereas dwell time isolates the waiting or idle intervals that can cause delays. Understanding these distinctions is critical for optimizing operational efficiency and reducing bottlenecks in supply chain management and manufacturing workflows.

Measuring Lead Time in Logistics and Supply Chain

Measuring lead time in logistics and supply chain involves tracking the total time from order placement to delivery, encompassing procurement, production, and transportation phases. Accurate lead time measurement improves demand forecasting, inventory management, and customer satisfaction by identifying delays and optimizing workflows. Utilizing real-time data analytics and integrated supply chain management systems enhances precision in lead time calculation and operational efficiency.

Calculating Dwell Time: Methods and Metrics

Dwell time is calculated by measuring the total time a user spends actively engaging with a page or content before returning to the search results or exiting. Common methods include tracking the timestamp difference between the user's click on a search result and their subsequent action, often using analytics tools like Google Analytics or clickstream data. Key metrics to evaluate dwell time effectiveness involve average session duration, bounce rate, and time-on-page, providing insights into user intent and content relevance.

Factors Influencing Lead Time and Dwell Time

Lead time is influenced by factors such as order processing speed, supplier reliability, production capacity, and transportation efficiency, while dwell time is primarily affected by warehouse space availability, inventory handling processes, and customs clearance speed. Variability in supply chain coordination and demand forecasting accuracy also impact lead time, whereas storage conditions and equipment performance play critical roles in determining dwell time. Understanding these factors enables businesses to optimize supply chain operations and reduce overall cycle times.

Impact of Lead Time and Dwell Time on Operational Efficiency

Lead time directly affects operational efficiency by determining the speed at which products move from order to delivery, influencing inventory management and customer satisfaction. Dwell time impacts efficiency through the duration materials or goods remain idle within a process, affecting throughput and resource utilization. Optimizing both lead time and dwell time reduces delays, lowers costs, and enhances overall workflow performance in supply chain and manufacturing operations.

Strategies to Reduce Lead Time and Dwell Time

Reducing lead time and dwell time requires implementing lean manufacturing principles, such as just-in-time inventory management and continuous process improvement to eliminate waste and delays. Leveraging advanced technology like real-time tracking systems and automated scheduling can optimize workflows and increase operational efficiency. Collaborating closely with suppliers and logistics providers ensures faster material flow and minimizes bottlenecks during production and transportation phases.

Conclusion: Optimizing Processes with Lead Time and Dwell Time Insights

Optimizing processes by analyzing lead time and dwell time enhances operational efficiency and resource allocation. Reducing lead time accelerates overall production cycles, while minimizing dwell time decreases idle periods, collectively improving throughput. Leveraging insights from both metrics supports data-driven decision-making, enabling continuous process improvement and cost reduction.

Lead time Infographic

libterm.com

libterm.com