Drilling involves creating precise holes in various materials using specialized equipment designed for efficiency and accuracy. Techniques vary depending on the industry, from oil and gas extraction to construction and manufacturing. Discover more about drilling methods and how to optimize your processes by reading the rest of this article.

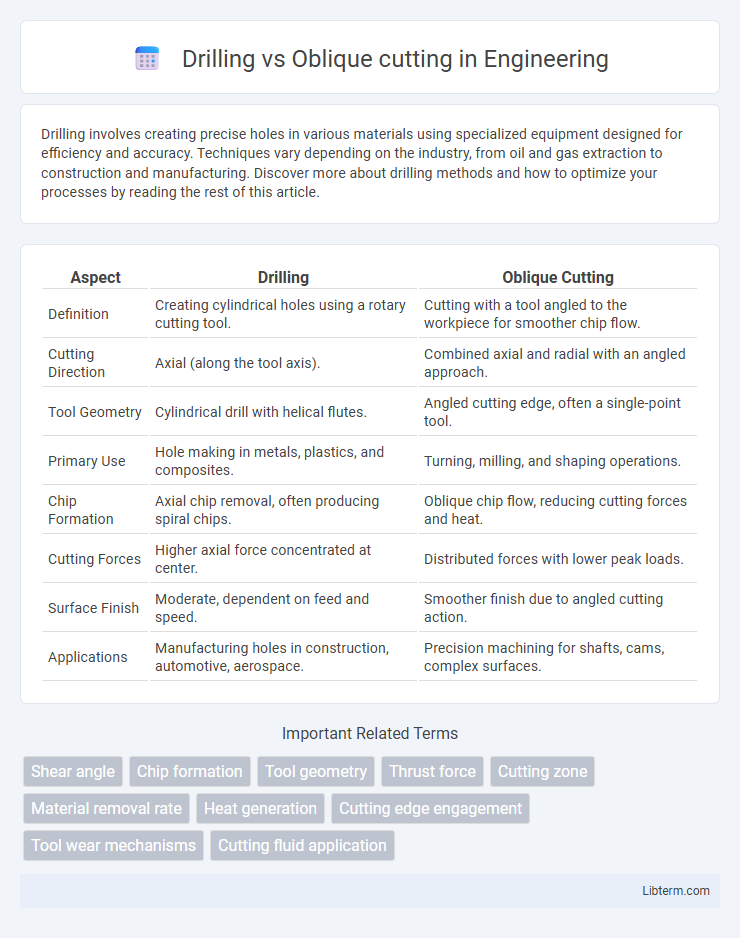

Table of Comparison

| Aspect | Drilling | Oblique Cutting |

|---|---|---|

| Definition | Creating cylindrical holes using a rotary cutting tool. | Cutting with a tool angled to the workpiece for smoother chip flow. |

| Cutting Direction | Axial (along the tool axis). | Combined axial and radial with an angled approach. |

| Tool Geometry | Cylindrical drill with helical flutes. | Angled cutting edge, often a single-point tool. |

| Primary Use | Hole making in metals, plastics, and composites. | Turning, milling, and shaping operations. |

| Chip Formation | Axial chip removal, often producing spiral chips. | Oblique chip flow, reducing cutting forces and heat. |

| Cutting Forces | Higher axial force concentrated at center. | Distributed forces with lower peak loads. |

| Surface Finish | Moderate, dependent on feed and speed. | Smoother finish due to angled cutting action. |

| Applications | Manufacturing holes in construction, automotive, aerospace. | Precision machining for shafts, cams, complex surfaces. |

Introduction to Drilling and Oblique Cutting

Drilling involves creating cylindrical holes by rotating a drill bit along its axis, commonly used in manufacturing and construction for precision hole-making. Oblique cutting employs a cutting tool set at an angle to the workpiece, producing shearing action that improves surface finish and reduces cutting forces in turning or milling operations. Both processes are fundamental in machining, with drilling focusing on hole formation and oblique cutting enhancing material removal efficiency.

Fundamental Principles of Drilling

Drilling involves creating cylindrical holes by rotating a drill bit perpendicular to the material surface, ensuring precise axial penetration driven by a combination of rotational and feed motions. The fundamental principles of drilling emphasize controlled cutting speed, feed rate, and drill geometry to optimize chip removal and minimize tool wear. Unlike oblique cutting, which engages the workpiece at an angle to generate shear forces along a plane, drilling relies on symmetric cutting edges producing axial forces for efficient hole formation.

Core Concepts of Oblique Cutting

Oblique cutting involves the cutting edge engaging the material at an angle, resulting in a shearing action that produces smoother surface finishes and reduced cutting forces compared to drilling. The core concepts include the direction of the cutting velocity vector, which is inclined relative to the workpiece surface, and the generation of a continuous chip that minimizes workpiece deformation. This method enhances tool life and efficiency by distributing cutting forces over a larger area, contrasting with the perpendicular engagement seen in conventional drilling.

Key Differences Between Drilling and Oblique Cutting

Drilling involves creating round holes by rotating a drill bit perpendicularly into the material, producing chips that are removed through the drill flutes. Oblique cutting, however, uses a cutting tool set at an angle to the surface, resulting in a shearing action that produces thinner, continuous chips and reduces cutting forces. The primary differences lie in the tool orientation, chip formation, and the direction of cutting forces, with drilling focused on axial penetration and oblique cutting emphasizing angled material removal.

Tool Geometry and Mechanics Comparison

Drilling involves axial cutting with a cylindrical tool featuring a chisel edge and helical flutes designed for chip evacuation, whereas oblique cutting uses a tool with an inclined cutting edge creating a shearing action. The geometry of drilling tools includes a point angle and lip relief that control penetration and chip flow, contrasting with oblique cutting tools that feature an angled rake and clearance face to optimize cutting forces. Mechanically, drilling induces high thrust forces and torque due to simultaneous chisel edge plowing and cutting lips, while oblique cutting reduces cutting forces by directing them at an angle, improving surface finish and tool life.

Material Removal Efficiency: Drilling vs Oblique Cutting

Material removal efficiency in drilling is generally lower due to the axial thrust and chip evacuation challenges, often resulting in slower cutting speeds and higher energy consumption. Oblique cutting optimizes the shear angle and chip flow direction, enhancing material removal rates and reducing cutting forces. This advantage makes oblique cutting more efficient for applications requiring rapid material removal and improved surface finish.

Surface Finish and Quality Outcomes

Oblique cutting produces a superior surface finish compared to drilling due to the shearing action that reduces cutting forces and minimizes material deformation. Drilling often results in rougher surfaces with potential for burrs and tool marks because of the axial cutting force and chip entanglement in deep holes. Surface quality in oblique cutting is enhanced by smoother chip flow and reduced heat generation, promoting better dimensional accuracy and extended tool life.

Typical Applications and Use Cases

Drilling is primarily used for creating precise, round holes in materials such as metal, wood, and plastic, commonly applied in manufacturing, construction, and maintenance tasks. Oblique cutting involves angled or slanted cuts, ideal for shaping edges, chamfering, and material removal in metalworking, woodworking, and milling operations. Typical use cases for drilling include hole preparation for fasteners or wiring, while oblique cutting is essential for tooling, deburring, and complex contouring processes.

Challenges and Limitations of Each Method

Drilling faces challenges such as limited precision in creating angled holes and potential tool deflection, which can compromise hole accuracy and surface finish. Oblique cutting allows for better control over chip formation and surface quality but is limited by increased tool wear and complexity in tool design and setup. Both methods require careful consideration of material properties and machining parameters to optimize performance and minimize operational difficulties.

Selecting the Right Technique for Your Project

Choosing between drilling and oblique cutting depends on material type, required precision, and project complexity. Drilling excels in creating cylindrical holes with high accuracy, ideal for tasks needing exact depth and diameter. Oblique cutting suits angled or tapered cuts, offering versatility for shaping and contouring materials like metals and composites.

Drilling Infographic

libterm.com

libterm.com