Fink truss structures optimize material use by distributing loads efficiently through triangular web members, enhancing strength and stability in bridges and roof supports. This design reduces weight while maintaining high durability, making it ideal for residential and commercial construction projects. Explore this article to discover how a Fink truss can improve your building's structural integrity.

Table of Comparison

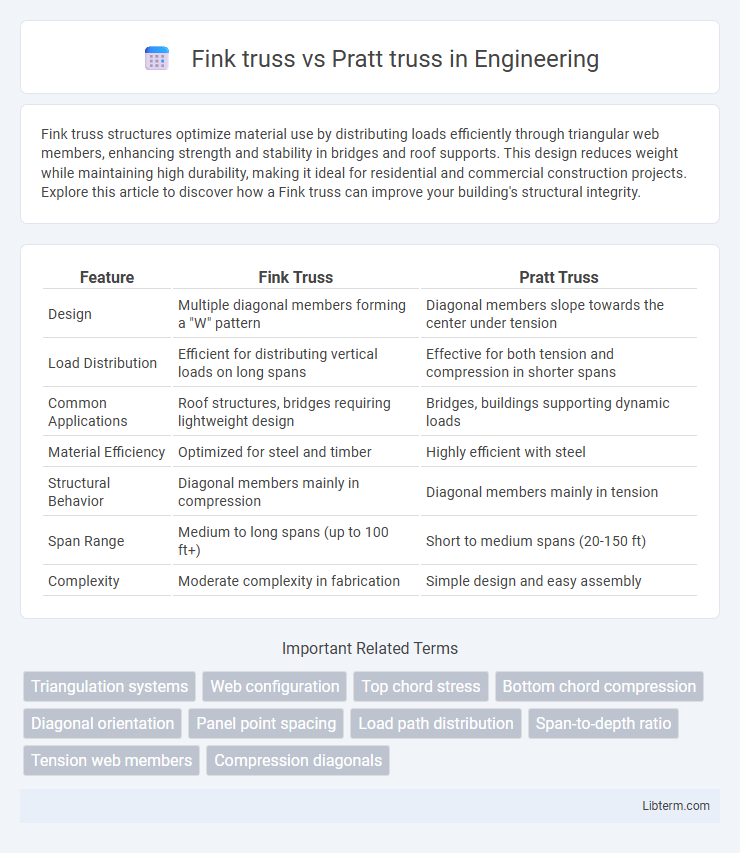

| Feature | Fink Truss | Pratt Truss |

|---|---|---|

| Design | Multiple diagonal members forming a "W" pattern | Diagonal members slope towards the center under tension |

| Load Distribution | Efficient for distributing vertical loads on long spans | Effective for both tension and compression in shorter spans |

| Common Applications | Roof structures, bridges requiring lightweight design | Bridges, buildings supporting dynamic loads |

| Material Efficiency | Optimized for steel and timber | Highly efficient with steel |

| Structural Behavior | Diagonal members mainly in compression | Diagonal members mainly in tension |

| Span Range | Medium to long spans (up to 100 ft+) | Short to medium spans (20-150 ft) |

| Complexity | Moderate complexity in fabrication | Simple design and easy assembly |

Introduction to Fink and Pratt Trusses

Fink and Pratt trusses are widely used in bridge and roof construction, offering distinct load distribution benefits. The Fink truss features a central vertical member with diagonal members extending outward to support loads efficiently, ideal for short-to-medium spans. In contrast, the Pratt truss has diagonal members slanting towards the center, optimizing tension and compression forces, making it suitable for longer spans and heavier loads.

Historical Background of Fink and Pratt Trusses

The Fink truss, patented by Albert Fink in 1854, revolutionized the design of railroad bridges with its efficient use of iron and triangular web patterns. The Pratt truss, introduced by Thomas and Caleb Pratt in 1844, became widely adopted for bridges due to its diagonal members which handle tensile forces and vertical members in compression, optimizing material use. Both truss designs significantly influenced 19th-century bridge engineering by addressing the challenges of longer spans and heavier loads during the Industrial Revolution.

Structural Design and Geometry Comparison

The Fink truss features a distinctive web pattern with multiple diagonal members extending from the top chord to a central bottom chord, optimizing load distribution and reducing bending moments in roof structures. In contrast, the Pratt truss employs vertical members under compression and diagonals slanting towards the center under tension, creating an efficient geometry for handling variable loads in bridges and buildings. The Fink truss's angular design suits shorter spans with concentrated loads, while the Pratt truss's rectangular geometry excels in longer spans requiring uniform load distribution.

Load Distribution in Fink vs Pratt Truss

Fink truss design features multiple diagonal members that efficiently distribute compressive and tensile forces, optimizing load transfer across shorter spans in roof structures. Pratt truss employs vertical members in compression and diagonal members in tension, favoring longer spans and effectively managing heavy loads with a focus on minimizing material use. Load distribution in Fink trusses is more centralized with shorter element lengths, while Pratt trusses enable greater span efficiency through their distinctive tension-compression member arrangement.

Materials Used for Fink and Pratt Trusses

Fink trusses typically use steel or wood, with steel favored for its high tensile strength and wood preferred in residential construction for cost efficiency and ease of fabrication. Pratt trusses often employ steel due to its superior performance under alternating tension and compression forces, but timber and reinforced concrete are also common in certain applications. Material selection for both trusses depends on load requirements, span length, environmental conditions, and economic factors.

Applications and Common Uses

Fink trusses are commonly used in residential and commercial roofing due to their efficient load distribution and material savings, ideal for medium to long spans. Pratt trusses excel in bridge construction and industrial buildings where they support heavy loads and provide excellent stability with their diagonal members under tension. Both truss types are favored in structural engineering for optimizing strength-to-weight ratios but differ in suitability based on span length and load requirements.

Advantages of Fink Truss

The Fink truss provides superior load distribution by using shorter, angled web members that efficiently transfer forces, reducing stress on the chords compared to the Pratt truss. Its design enables the use of lighter materials while maintaining high strength, making it ideal for longer spans and heavy loads in bridge and roof construction. The repetitive triangular pattern enhances structural stability and simplifies fabrication and assembly, contributing to reduced construction costs.

Advantages of Pratt Truss

Pratt truss offers superior efficiency in handling dynamic loads due to its diagonal members designed to withstand tension, making it ideal for railroad and highway bridges. Its straightforward design reduces material costs and simplifies fabrication and maintenance compared to the Fink truss. This structural advantage results in greater load-bearing capacity and flexibility in longer span applications.

Limitations and Challenges

Fink trusses face limitations in handling heavy loads over long spans due to their numerous web members, which can increase material costs and complicate construction. Pratt trusses encounter challenges with compression members, making them less efficient under certain load conditions and prone to buckling if not properly designed. Both truss types require precise engineering and maintenance to prevent structural failures and ensure durability.

Cost Considerations and Selection Criteria

Fink trusses generally offer cost advantages in residential construction due to their efficient material use and simplified fabrication, making them ideal for shorter spans and lighter loads. Pratt trusses, while often more expensive, provide superior strength and versatility for longer spans and heavier loads, justifying higher initial costs in commercial or industrial applications. Selection criteria balance project budget, span requirements, load capacity, and fabrication complexity to determine the most cost-effective truss design.

Fink truss Infographic

libterm.com

libterm.com