Universal motors are versatile electric motors capable of operating on both AC and DC power sources, making them ideal for portable tools and household appliances. Their high-speed operation and compact size allow for efficient performance in devices like vacuum cleaners and blenders. Discover how a universal motor can enhance your appliances by reading the full article.

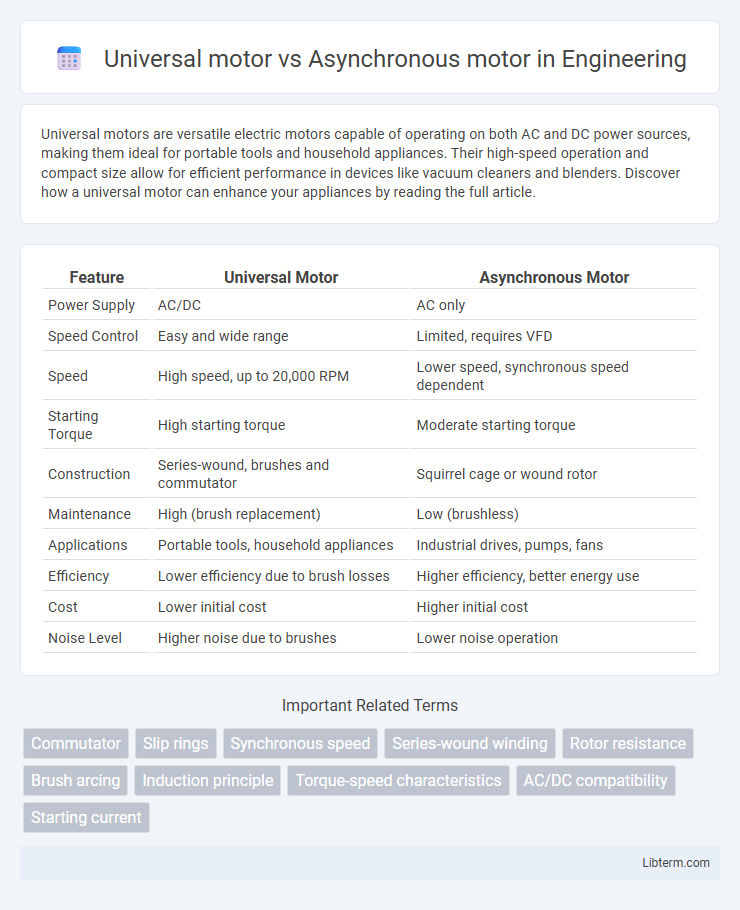

Table of Comparison

| Feature | Universal Motor | Asynchronous Motor |

|---|---|---|

| Power Supply | AC/DC | AC only |

| Speed Control | Easy and wide range | Limited, requires VFD |

| Speed | High speed, up to 20,000 RPM | Lower speed, synchronous speed dependent |

| Starting Torque | High starting torque | Moderate starting torque |

| Construction | Series-wound, brushes and commutator | Squirrel cage or wound rotor |

| Maintenance | High (brush replacement) | Low (brushless) |

| Applications | Portable tools, household appliances | Industrial drives, pumps, fans |

| Efficiency | Lower efficiency due to brush losses | Higher efficiency, better energy use |

| Cost | Lower initial cost | Higher initial cost |

| Noise Level | Higher noise due to brushes | Lower noise operation |

Introduction to Universal and Asynchronous Motors

Universal motors operate on both AC and DC power sources, featuring series-wound armature and field coils that produce high starting torque and variable speed control, making them ideal for portable power tools and household appliances. Asynchronous motors, also known as induction motors, rely on electromagnetic induction to generate rotor currents and torque without electrical connections to the rotor, commonly used in industrial applications for their robustness, low maintenance, and efficiency in constant-speed operations. The key difference lies in their construction and operation: universal motors use brushes and commutators for current conduction, while asynchronous motors have a squirrel-cage rotor with slip to induce rotation.

Operating Principles: Universal vs Asynchronous Motors

Universal motors operate on the principle of electromagnetic induction, utilizing both AC and DC power by combining series-wound field coils and an armature, enabling high-speed operation and variable speed control. Asynchronous motors, also known as induction motors, function based on the rotor rotating at a speed slightly less than the stator's rotating magnetic field, generating torque through induced currents without electrical connection to the rotor. The fundamental difference in operating principles lies in the universal motor's commutator and brushes facilitating current flow, whereas the asynchronous motor relies on electromagnetic induction without mechanical contacts.

Key Construction Differences

Universal motors feature a series-wound stator and rotor winding on a laminated iron core, enabling high starting torque and operation on both AC and DC power sources. Asynchronous motors, also known as induction motors, consist of a stationary stator with three-phase windings and a rotor made of conductive bars short-circuited by end rings, relying on electromagnetic induction for torque production. The universal motor's compact design and commutator-brush assembly contrast sharply with the simple, robust squirrel-cage structure of the asynchronous motor.

Performance and Efficiency Comparison

Universal motors offer high starting torque and variable speed control, making them suitable for portable power tools and household appliances, but their efficiency typically ranges between 20-35% due to significant energy losses from brush friction and armature winding resistance. Asynchronous motors, commonly known as induction motors, provide better efficiency rates of 80-90% and more reliable performance in industrial applications, benefiting from a rugged design with fewer maintenance requirements and steady speed under varying loads. Although universal motors excel in versatility and quick acceleration, asynchronous motors outperform them in energy efficiency and durability, especially in continuous operation scenarios.

Voltage and Power Supply Requirements

Universal motors operate on both AC and DC voltage, typically requiring a single-phase power supply with voltages ranging from 110V to 240V, making them suitable for portable and household appliances. Asynchronous motors, also known as induction motors, primarily run on three-phase AC power supplies, commonly with voltages of 380V or 415V, designed for industrial and heavy-duty applications. The universal motor's flexibility in voltage compatibility contrasts with the asynchronous motor's need for stable, high-voltage AC power to ensure efficient performance.

Speed Control Capabilities

Universal motors offer superior speed control capabilities due to their ability to operate on both AC and DC power sources and their design, which allows for easy variation of voltage and current. This enables rapid changes in speed, making them ideal for applications requiring high-speed operation and fine speed adjustments, such as power tools and household appliances. In contrast, asynchronous motors, typically induction motors, have fixed speeds determined by the supply frequency and rotor slip, requiring complex variable frequency drives (VFDs) for effective speed control.

Typical Applications of Universal Motors

Universal motors are predominantly found in portable power tools, household appliances like vacuum cleaners and blenders, and sewing machines due to their high starting torque and ability to operate on both AC and DC power supplies. Their compact size and lightweight construction make them ideal for applications requiring variable speed control and rapid acceleration. Unlike asynchronous motors, which are common in industrial fans and pumps, universal motors excel in small, high-speed devices where size and speed versatility are crucial.

Common Uses of Asynchronous Motors

Asynchronous motors, commonly known as induction motors, are widely used in industrial applications such as pumps, conveyors, and fans due to their robust design and efficiency. These motors operate on electromagnetic induction principles, providing reliable performance in fixed-speed tasks and heavy-duty machinery. Their widespread use in HVAC systems, compressors, and manufacturing equipment highlights their adaptability and cost-effectiveness compared to universal motors, which are typically found in portable power tools and household appliances.

Advantages and Disadvantages

Universal motors offer high-speed operation and compact size, making them ideal for portable power tools and household appliances; they can run on both AC and DC power but tend to be noisy and have a shorter lifespan due to brush and commutator wear. Asynchronous motors, also known as induction motors, are robust, low-maintenance, and efficient for continuous industrial applications, yet they typically operate at lower speeds and require a constant power supply, limiting their use in variable-speed scenarios. Choosing between these motors depends on factors like torque requirements, operational environment, and maintenance capabilities.

Choosing the Right Motor for Your Application

Universal motors offer high speed and variable control, making them ideal for portable tools and household appliances requiring compact size and quick response. Asynchronous motors, also known as induction motors, provide robust and efficient performance for industrial applications needing continuous operation and low maintenance. Selecting the right motor depends on application requirements such as speed variability, power source, size constraints, and duty cycle.

Universal motor Infographic

libterm.com

libterm.com