A stress concentrator is a point in a material where stress is significantly higher than the surrounding area, often due to geometric discontinuities like cracks, holes, or notches. These localized increases in stress can lead to material failure if not properly managed in design and engineering. Discover how understanding stress concentrators can help you enhance the durability of your structures by reading the rest of this article.

Table of Comparison

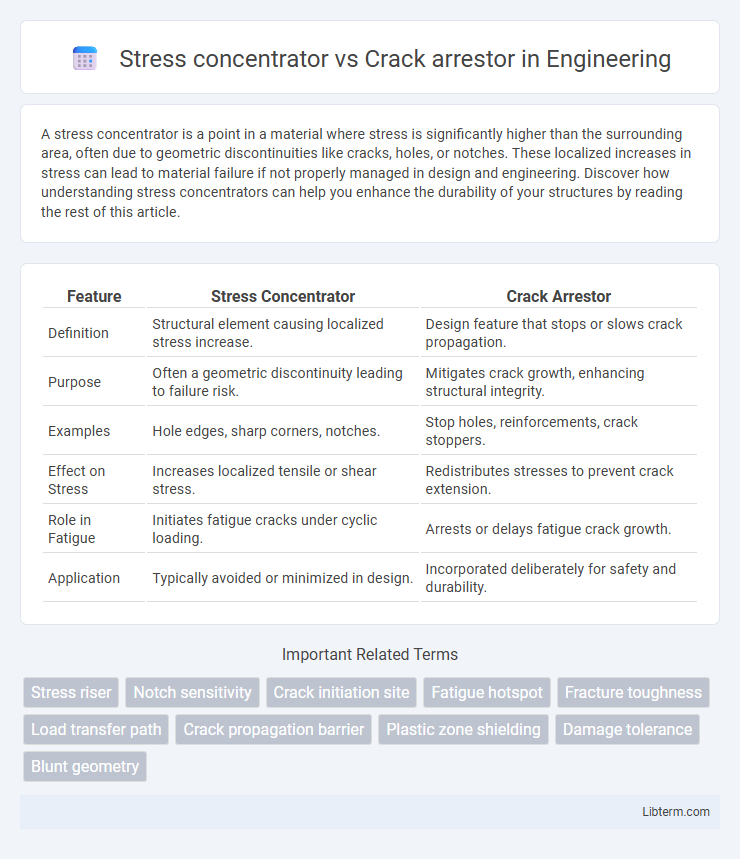

| Feature | Stress Concentrator | Crack Arrestor |

|---|---|---|

| Definition | Structural element causing localized stress increase. | Design feature that stops or slows crack propagation. |

| Purpose | Often a geometric discontinuity leading to failure risk. | Mitigates crack growth, enhancing structural integrity. |

| Examples | Hole edges, sharp corners, notches. | Stop holes, reinforcements, crack stoppers. |

| Effect on Stress | Increases localized tensile or shear stress. | Redistributes stresses to prevent crack extension. |

| Role in Fatigue | Initiates fatigue cracks under cyclic loading. | Arrests or delays fatigue crack growth. |

| Application | Typically avoided or minimized in design. | Incorporated deliberately for safety and durability. |

Introduction to Stress Concentrators and Crack Arrestors

Stress concentrators are features or flaws in materials that cause localized increases in stress, often leading to failure initiation, while crack arrestors are design elements or treatments used to stop or slow crack propagation in structural components. Stress concentrators include geometric irregularities such as holes, notches, and sharp corners, which amplify stress beyond the nominal levels. Crack arrestors are strategically placed barriers, such as drilled holes at crack tips or material transitions, designed to redistribute stress and prevent catastrophic fractures.

Understanding Stress Concentrators: Definition and Examples

Stress concentrators are localized regions in a material where stress is significantly amplified due to geometric discontinuities such as holes, notches, or sharp corners. These stress risers can initiate cracks by concentrating forces, leading to potential structural failure under repeated loading or high stress conditions. Understanding the role of stress concentrators is crucial for designing components with minimized risk of crack initiation and enhancing durability through proper material selection and geometry optimization.

The Role of Crack Arrestors in Material Integrity

Crack arrestors are critical components designed to prevent the propagation of cracks by redistributing stress and dissipating energy at potential fracture points, significantly enhancing material integrity. Unlike stress concentrators, which amplify stress and facilitate crack initiation, crack arrestors interrupt crack growth and reduce the risk of catastrophic failure in structural materials. Their implementation in engineering applications improves durability and safety by maintaining the continuity and mechanical performance of components under cyclic or impact loading.

Mechanisms of Stress Concentration in Structural Materials

Stress concentrators in structural materials arise from geometrical discontinuities such as notches, holes, and sudden changes in cross-section that amplify localized stress levels beyond the nominal applied stress. These stress concentrations serve as initiation sites for cracks by creating microstructural strain gradients and stress intensity factors that exceed material yield strength. Crack arrestors function by interrupting crack propagation paths through mechanisms like crack path deflection, plastic zone enlargement, or toughening inclusions, effectively reducing the stress intensity factor and enhancing structural durability.

How Crack Arrestors Mitigate Crack Propagation

Crack arrestors mitigate crack propagation by redistributing stress concentrations away from the crack tip, thereby reducing the likelihood of crack growth under cyclic loading or sudden impact. Unlike stress concentrators, which amplify localized stresses and promote crack initiation, crack arrestors introduce geometric or material discontinuities that absorb and dissipate energy, effectively halting crack advancement. This strategic interruption of stress flow prolongs structural integrity and enhances fatigue resistance in critical components.

Stress Concentrator vs Crack Arrestor: Key Differences

Stress concentrators are localized regions in a material where stress is significantly higher than the surrounding area, often caused by geometric discontinuities such as holes, notches, or sharp corners. Crack arrestors are design features or material treatments intended to stop or slow the propagation of cracks by redistributing stress or increasing the fracture toughness at critical points. The key difference lies in their function: stress concentrators increase the likelihood of crack initiation, while crack arrestors mitigate crack growth and improve structural integrity.

Materials and Designs for Effective Crack Arrestors

Materials such as high-toughness steel, fiber-reinforced composites, and layered metal laminates serve as effective crack arrestors by dissipating energy and impeding crack propagation. Design strategies include introducing geometric discontinuities like holes or notches to redistribute stress concentration away from critical areas while incorporating interfaces or barriers that blunt the crack tip. Advanced crack arrestor designs utilize graded material properties and hybrid structures to optimize resistance, enhancing overall structural integrity compared to conventional stress concentrators.

Real-world Applications: Where Stress Concentrators Matter

Stress concentrators are critical in structural engineering applications such as bridge joints and turbine blades, where sharp corners or abrupt changes in geometry can localize stress and initiate failure. Components like bolt holes, notches, and keyways serve as intentional stress concentrators to predict and manage crack initiation in aerospace and automotive industries. Understanding and controlling stress concentrators enable improved fatigue life and safety in high-stress environments.

Advances in Engineering: Modern Crack Arrestor Technologies

Modern crack arrestor technologies integrate advanced materials such as fiber-reinforced polymers and additive manufacturing techniques to enhance structural integrity by mitigating stress concentrators effectively. These innovations enable dynamic redistribution of stress around crack tips, significantly delaying crack propagation and improving fatigue resistance in aerospace and civil engineering applications. Computational modeling and real-time sensor integration provide optimized designs that tailor crack arrestors to specific load conditions, advancing predictive maintenance and extending service life of critical components.

Future Trends in Stress Management and Crack Prevention

Advancements in material science and computational modeling are enhancing the design of stress concentrators and crack arrestors to optimize structural integrity. Future trends emphasize the integration of smart materials and nanoscale reinforcements that adaptively distribute stress and halt crack propagation in real-time. Machine learning algorithms are predictive tools for identifying potential crack initiation sites, enabling proactive maintenance and improved durability in engineering applications.

Stress concentrator Infographic

libterm.com

libterm.com