Casting is a crucial process in manufacturing where molten material is poured into a mold to create complex shapes with precision and efficiency. This technique allows for the production of components in various metals and plastics, ensuring structural integrity and detailed features. Explore the rest of the article to understand how casting can enhance your production capabilities.

Table of Comparison

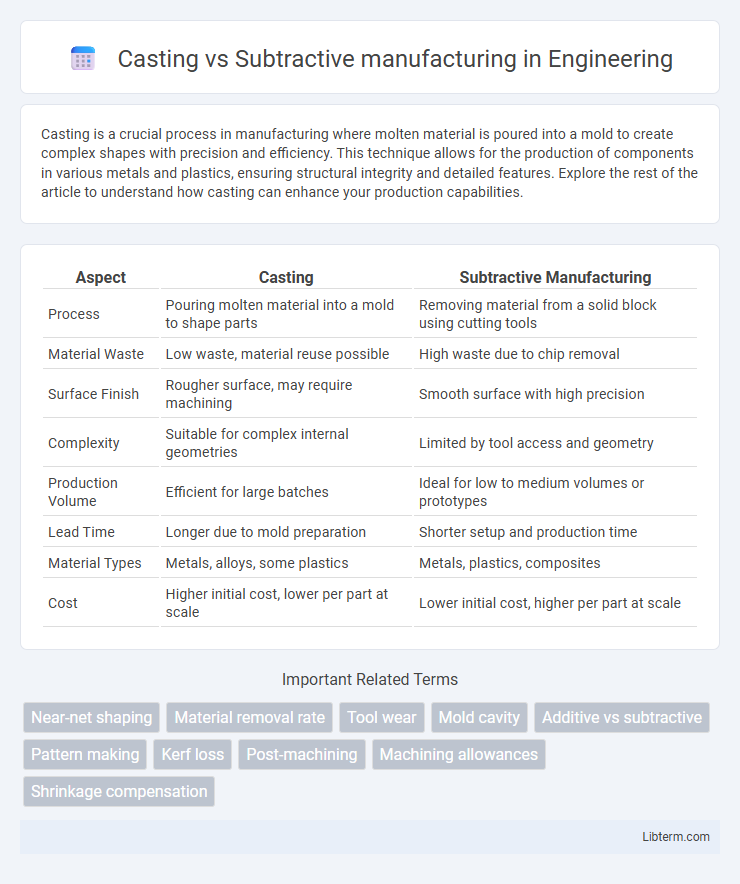

| Aspect | Casting | Subtractive Manufacturing |

|---|---|---|

| Process | Pouring molten material into a mold to shape parts | Removing material from a solid block using cutting tools |

| Material Waste | Low waste, material reuse possible | High waste due to chip removal |

| Surface Finish | Rougher surface, may require machining | Smooth surface with high precision |

| Complexity | Suitable for complex internal geometries | Limited by tool access and geometry |

| Production Volume | Efficient for large batches | Ideal for low to medium volumes or prototypes |

| Lead Time | Longer due to mold preparation | Shorter setup and production time |

| Material Types | Metals, alloys, some plastics | Metals, plastics, composites |

| Cost | Higher initial cost, lower per part at scale | Lower initial cost, higher per part at scale |

Introduction to Casting and Subtractive Manufacturing

Casting involves pouring molten material into a mold to create complex shapes with high dimensional accuracy and minimal material waste. Subtractive manufacturing, also known as CNC machining, removes material from a solid block using cutting tools to achieve precise geometries and tight tolerances. Both methods serve different production needs, with casting ideal for large-scale parts and subtractive manufacturing suited for prototypes and intricate components.

Defining Casting: Processes and Materials

Casting involves pouring molten metal or other materials into a mold to achieve a specific shape upon solidification, commonly utilizing metals like aluminum, steel, and cast iron. This process includes variations such as sand casting, die casting, and investment casting, each suited for different applications based on precision and production volume. Materials selection in casting depends on factors like melting point, fluidity, and alloy composition to ensure optimal mechanical properties and surface finish.

Overview of Subtractive Manufacturing Methods

Subtractive manufacturing methods involve removing material from a solid block or billet using cutting, drilling, milling, or grinding techniques to achieve the desired shape and dimensions. Common technologies include CNC machining, where computer-controlled tools provide high precision and repeatability, and traditional methods like manual milling and turning. These processes offer advantages in producing complex geometries with tight tolerances and superior surface finishes compared to casting.

Key Differences Between Casting and Subtractive Techniques

Casting involves pouring molten material into a mold to create a shape, while subtractive manufacturing removes material from a solid block using CNC machines or milling tools. Casting allows for complex geometries and internal cavities, but subtractive techniques offer higher precision and tighter tolerances. The material waste is minimal in casting, whereas subtractive manufacturing typically generates more scrap due to material removal processes.

Material Compatibility and Selection

Casting offers broad material compatibility, allowing the use of metals, alloys, and plastics with varying melting points and compositions suitable for complex geometries. Subtractive manufacturing excels with materials that have uniform hardness and stability, such as aluminum, steel, and certain polymers, enabling precise machining and surface finishes. Material selection in casting prioritizes fluidity and solidification characteristics, while subtractive manufacturing emphasizes machinability and tool wear resistance.

Surface Finish and Dimensional Accuracy Comparison

Casting typically results in rougher surface finishes due to mold textures and solidification irregularities, often requiring secondary machining for smoothness; surface roughness values range from 3.2 to 12.5 micrometers Ra. Subtractive manufacturing, such as CNC milling, achieves finer surface finishes with typical Ra values between 0.4 and 1.6 micrometers, offering superior dimensional accuracy within +-0.01 mm tolerances. Dimensional accuracy in subtractive processes exceeds casting, which may have deviations up to +-0.5 mm depending on alloy and mold conditions.

Cost Analysis: Casting vs Subtractive Manufacturing

Casting offers significant cost advantages for high-volume production due to lower material waste and reduced machining requirements, which can lower overall expenses compared to subtractive manufacturing. Subtractive manufacturing incurs higher costs because it involves extensive material removal, increased tooling wear, and longer processing times, especially for complex or large parts. The initial setup and mold fabrication in casting may be expensive, but these costs are amortized over large production runs, resulting in lower per-unit costs relative to subtractive processes.

Production Speed and Scalability

Casting offers faster production speeds for high-volume runs due to its ability to create complex shapes in a single mold, enabling rapid replication once the mold is prepared. Subtractive manufacturing tends to be slower as it involves material removal processes like milling or CNC machining, which require more time per part, particularly for complex geometries. Scalability in casting is superior for mass production, as increasing output mainly involves producing more castings without significantly altering process parameters, whereas subtractive manufacturing scalability is limited by machine availability and longer cycle times per unit.

Environmental Impact and Waste Management

Casting generates significant waste due to mold materials and excess metal, which often require energy-intensive recycling processes, contributing to higher carbon emissions. Subtractive manufacturing produces more material waste through chip removal, but advances in recycling and machining techniques enable better recovery and reuse of metal scraps, reducing landfill contributions. Both processes impact energy consumption, but subtractive methods are increasingly optimized for waste management and environmental sustainability through precision material use and recycling integration.

Application Areas and Industry Use Cases

Casting is widely utilized in automotive and aerospace industries for producing complex metal parts like engine blocks and turbine blades, offering cost-effective solutions for high-volume production. Subtractive manufacturing is prevalent in aerospace and medical sectors, enabling precision machining of components such as turbine parts and surgical instruments from solid metal blocks. Both methods serve critical roles in manufacturing, with casting favored for bulk production and subtractive machining chosen for high-precision, low-volume applications.

Casting Infographic

libterm.com

libterm.com