Seam welding is a continuous welding process that joins metal sheets by applying pressure and heat generated by an electric current through rotating wheel electrodes. This technique ensures airtight and watertight joints, making it ideal for applications like automotive fuel tanks and metal containers. Explore this article to understand how seam welding can enhance the strength and durability of your metal fabrication projects.

Table of Comparison

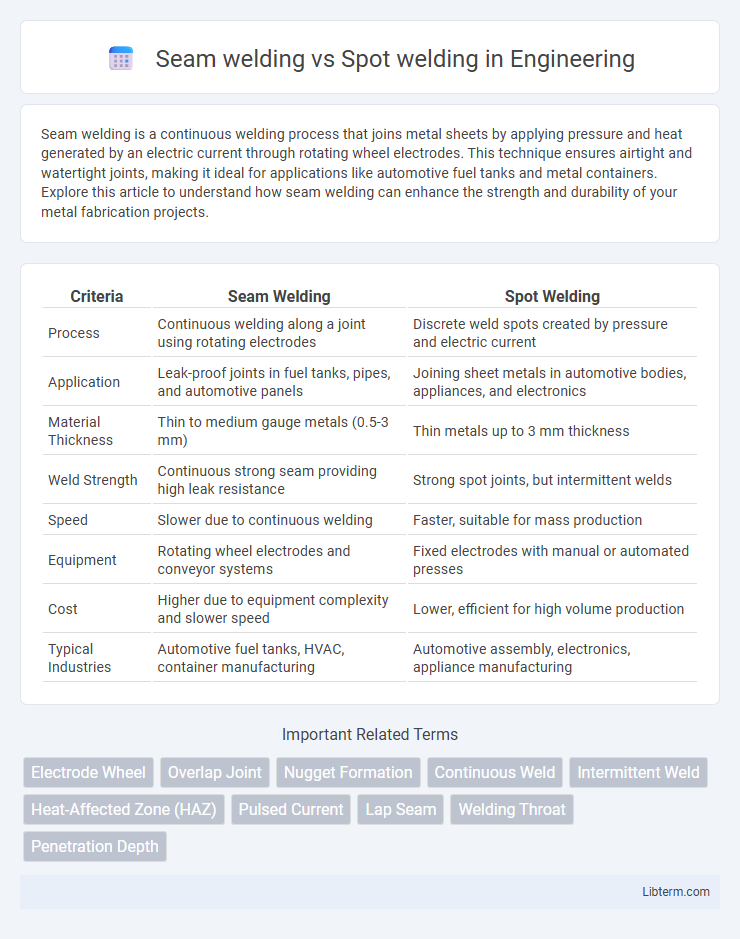

| Criteria | Seam Welding | Spot Welding |

|---|---|---|

| Process | Continuous welding along a joint using rotating electrodes | Discrete weld spots created by pressure and electric current |

| Application | Leak-proof joints in fuel tanks, pipes, and automotive panels | Joining sheet metals in automotive bodies, appliances, and electronics |

| Material Thickness | Thin to medium gauge metals (0.5-3 mm) | Thin metals up to 3 mm thickness |

| Weld Strength | Continuous strong seam providing high leak resistance | Strong spot joints, but intermittent welds |

| Speed | Slower due to continuous welding | Faster, suitable for mass production |

| Equipment | Rotating wheel electrodes and conveyor systems | Fixed electrodes with manual or automated presses |

| Cost | Higher due to equipment complexity and slower speed | Lower, efficient for high volume production |

| Typical Industries | Automotive fuel tanks, HVAC, container manufacturing | Automotive assembly, electronics, appliance manufacturing |

Introduction to Seam Welding and Spot Welding

Seam welding creates continuous, leak-tight joints by overlapping spots of resistance welds along a seam, primarily used in manufacturing fuel tanks, drums, and automotive parts. Spot welding joins metal sheets at specific points through localized heat generated by electrical resistance, making it ideal for assembling sheet metal components like car bodies. Both techniques rely on resistance welding principles but differ in application and joint type, with seam welding providing continuous welds and spot welding producing discrete weld spots.

Definitions and Basic Principles

Seam welding is a resistance welding process that creates a continuous, leak-tight joint by using rotating wheel electrodes to apply pressure and heat along the metal edges. Spot welding joins two or more metal sheets at discrete points by applying electric current and pressure through electrode tips, forming localized weld spots. Both methods rely on electrical resistance to generate heat but differ in their application and the nature of the weld produced.

Key Differences Between Seam Welding and Spot Welding

Seam welding creates a continuous, leak-proof joint by overlapping metal sheets and applying heat and pressure through rotating wheel electrodes, ideal for manufacturing tanks and pipes. Spot welding uses stationary electrodes to join discrete points, making it suitable for applications requiring quick, strong welds such as automotive body panels. Key differences include seam welding's continuous weld pattern versus spot welding's intermittent weld spots, and the use of moving wheels compared to fixed electrodes.

Materials Suitable for Seam and Spot Welding

Seam welding excels with ductile metals such as stainless steel, aluminum, and low-carbon steel due to its ability to create continuous, leak-proof joints ideal for fuel tanks and automotive components. Spot welding is suited for thin sheet metals like galvanized steel and aluminum alloys commonly used in automotive body panels and electronic enclosures, where rapid, localized heat generates strong weld spots. Material thickness and thermal conductivity significantly influence the choice, with spot welding preferred for thinner materials and seam welding effective for continuous welds on thicker or coated metals.

Equipment and Technology Used

Seam welding utilizes rotary wheel electrodes and continuous current power supplies to create long, leak-tight welds along metal sheets, making it ideal for applications requiring airtight seals like fuel tanks and pipes. Spot welding employs stationary copper electrodes connected to a high-current discharge source, typically a capacitor discharge or transformer, to join overlapping metal sheets at discrete points, commonly used in automotive body assembly. Advanced seam welding machines integrate precision controls and automated guides for consistent weld quality, while spot welding technology benefits from rapid cycle times and adaptive force control systems to optimize joint strength and minimize material distortion.

Strength and Durability Comparison

Seam welding creates continuous joints by overlapping spot welds, resulting in higher strength and superior durability compared to spot welding, which forms discrete, individual weld points. The continuous weld in seam welding provides better resistance to fatigue, leaks, and stress, making it ideal for applications requiring airtight or watertight seals. Spot welding, while faster and cost-effective for thinner materials, typically exhibits lower tensile strength and durability under cyclic loading conditions.

Applications in Various Industries

Seam welding is extensively used in the automotive and aerospace industries for creating leak-proof and continuous joints in fuel tanks, exhaust systems, and air conditioning components. Spot welding is preferred in manufacturing electrical panels, battery packs, and metal furniture due to its efficiency in joining sheet metals rapidly at discrete points. Both methods enhance production speed and structural integrity across electronics, automotive, and appliance industries.

Advantages and Disadvantages

Seam welding offers continuous, airtight joints ideal for automotive fuel tanks and metal cans, providing superior corrosion resistance but requires precise control and higher setup costs. Spot welding enables fast, cost-effective joining of sheet metals with minimal distortion, widely used in automotive assemblies, though it has limited strength for thicker materials and leaves visible weld spots. Choosing between these methods depends on production speed, joint design, and application requirements.

Cost and Efficiency Analysis

Seam welding offers higher efficiency for continuous joints with reduced rework, leading to lower operational costs in long production runs compared to spot welding, which is more suited for discrete, short-duration welds but can incur higher labor and inspection expenses. Spot welding has lower initial equipment costs but may result in increased maintenance and material wastage due to inconsistent weld quality, while seam welding's automated process reduces labor input and improves repeatability, optimizing overall cost-effectiveness. Evaluating factors such as production volume, material thickness, and joint design is crucial for determining the most economical and efficient welding method for specific manufacturing needs.

Choosing the Right Welding Method

Seam welding creates a continuous, leak-proof joint ideal for cylindrical or sheet metal applications requiring airtight or watertight seals, while spot welding forms discrete weld points suited for joining overlapping metal sheets quickly and with high strength. Choosing the right welding method depends on factors such as material thickness, joint design, production speed, and desired weld appearance; seam welding excels in automotive fuel tanks and metal drums, whereas spot welding is preferred for automotive frames and appliance assemblies. Evaluating electrical conductivity, thermal conductivity, and mechanical stress resistance of the materials ensures optimal weld quality and durability.

Seam welding Infographic

libterm.com

libterm.com