Butt weld is a technique used to join two pieces of metal end-to-end, creating a strong and seamless connection essential in construction and manufacturing. Proper execution ensures durability and structural integrity, making it a preferred method for pipelines, pressure vessels, and structural components. Explore the article to understand the benefits and best practices of butt welds for your projects.

Table of Comparison

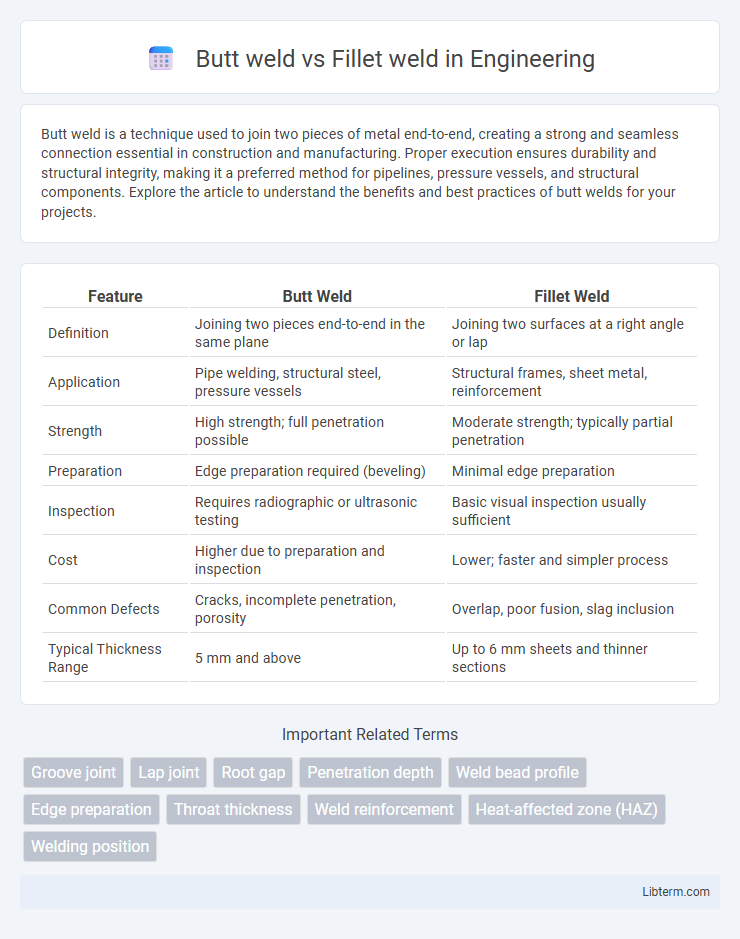

| Feature | Butt Weld | Fillet Weld |

|---|---|---|

| Definition | Joining two pieces end-to-end in the same plane | Joining two surfaces at a right angle or lap |

| Application | Pipe welding, structural steel, pressure vessels | Structural frames, sheet metal, reinforcement |

| Strength | High strength; full penetration possible | Moderate strength; typically partial penetration |

| Preparation | Edge preparation required (beveling) | Minimal edge preparation |

| Inspection | Requires radiographic or ultrasonic testing | Basic visual inspection usually sufficient |

| Cost | Higher due to preparation and inspection | Lower; faster and simpler process |

| Common Defects | Cracks, incomplete penetration, porosity | Overlap, poor fusion, slag inclusion |

| Typical Thickness Range | 5 mm and above | Up to 6 mm sheets and thinner sections |

Introduction to Butt Welds and Fillet Welds

Butt welds join two pieces of metal end-to-end, creating a strong, continuous joint often used in pipelines, pressure vessels, and structural applications. Fillet welds connect two surfaces at an approximate right angle, commonly employed in lap joints, T-joints, and corner welds for framing, brackets, and sheet metal work. Understanding the distinct applications and load-bearing capabilities of butt welds and fillet welds is essential for selecting the appropriate welding technique in fabrication and construction projects.

Definition and Characteristics of Butt Welds

Butt welds involve joining two pieces of metal along a single plane by fusing their edges, creating a continuous joint that is typically stronger and more airtight than other weld types. Characterized by their flat or slightly convex surface, butt welds provide excellent strength and are widely used in pipelines, pressure vessels, and structural applications due to their ability to withstand high stress and pressure. The fusion process ensures a uniform bond throughout the joint, minimizing defects and enhancing durability compared to fillet welds, which join metals at an angle without full edge fusion.

Definition and Characteristics of Fillet Welds

Fillet welds are triangular cross-section welds commonly used to join two surfaces at a right angle, forming a lap, T, or corner joint. Characterized by their ease of application and ability to accommodate misalignments, fillet welds typically do not require groove preparation like butt welds. Their strength depends on leg size and throat thickness, making them suitable for moderate load-bearing structures.

Applications of Butt Welds

Butt welds are extensively used in pipeline construction, structural steel fabrication, and pressure vessel manufacturing due to their strong, continuous joint that can withstand high stress and pressure. These welds provide full penetration, making them ideal for critical load-bearing applications and ensuring structural integrity in bridges, shipbuilding, and heavy machinery. Their efficient load transfer and sleek finish also make butt welds preferred in aerospace and automotive industries where precision and strength are paramount.

Applications of Fillet Welds

Fillet welds are predominantly used in applications requiring the joining of two surfaces at a right angle, such as in structural steel frameworks, shipbuilding, and automotive chassis fabrication. Their versatility allows for efficient welding of T-joints, lap joints, and corner joints, enhancing load distribution and resistance to shear forces. Common in manufacturing and construction industries, fillet welds provide strong, durable connections for components subjected to static and dynamic loads.

Strength and Performance Comparison

Butt welds provide superior strength and performance under dynamic and high-pressure conditions due to full penetration and uniform load distribution across the joint. Fillet welds, while easier to execute and effective for joining perpendicular or overlapping parts, generally exhibit lower strength and fatigue resistance compared to butt welds. In critical structural applications, butt welds are preferred for their enhanced durability and ability to sustain higher stress without compromising joint integrity.

Weld Joint Preparation Differences

Butt weld joint preparation involves aligning two pieces edge-to-edge, often requiring beveling or chamfering to ensure a proper weld groove and penetration. Fillet weld joint preparation typically involves overlapping or perpendicular surfaces without extensive edge treatment, focusing on clean, square edges to promote weld adhesion. Proper surface cleaning and precise fit-up are critical in both methods to avoid defects and ensure weld integrity.

Cost and Efficiency Considerations

Butt welds typically demand higher initial setup costs due to precise edge preparation and alignment but offer superior strength and minimal material usage, enhancing efficiency in high-stress applications. Fillet welds require less preparation and are faster to execute, resulting in lower labor costs and favorable efficiency for joining perpendicular or lap joints where strength requirements are moderate. Choosing between butt and fillet welds depends on balancing capital investment against operational efficiency and the specific structural performance needed.

Inspection and Testing Methods

Butt weld inspection commonly employs radiographic testing (RT) and ultrasonic testing (UT) to detect internal defects such as cracks, porosity, and incomplete fusion. Fillet welds are frequently evaluated using visual inspection combined with magnetic particle testing (MT) or dye penetrant testing (PT) to identify surface flaws and ensure adequate weld size and throat thickness. Both weld types often undergo mechanical testing, including bend tests and tensile tests, to verify weld strength and integrity according to relevant standards like ASME or AWS.

Choosing the Right Weld for Your Project

Butt welds provide strong, full-penetration joints ideal for high-stress applications where maximum strength and smooth finish are crucial, commonly used in pipelines and structural steel fabrication. Fillet welds are more versatile for joining perpendicular or lap joints, offering easier application and faster welding times, making them suitable for lighter loads and general fabrication tasks. Selecting the right weld depends on factors like load requirements, joint design, material thickness, and accessibility, ensuring optimal strength and structural integrity tailored to the specific project needs.

Butt weld Infographic

libterm.com

libterm.com