Mass production revolutionizes manufacturing by enabling the efficient creation of large quantities of standardized products, significantly reducing costs and production time. This method relies heavily on assembly lines and automation to maintain consistent quality and output. Discover how mass production can transform Your business operations by exploring the detailed benefits and challenges in the rest of this article.

Table of Comparison

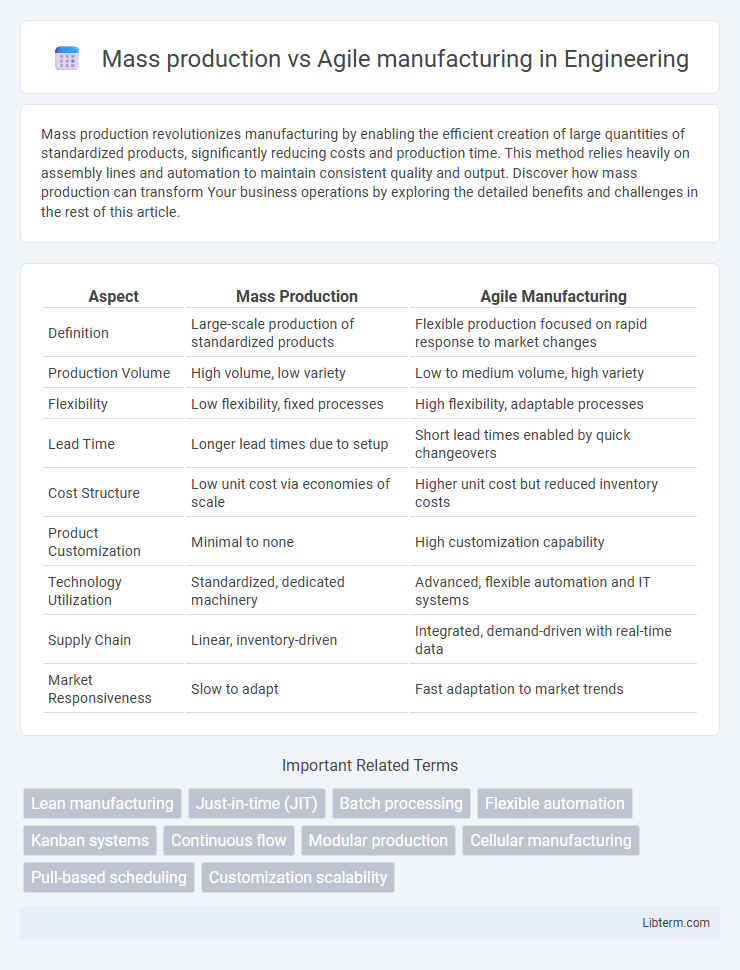

| Aspect | Mass Production | Agile Manufacturing |

|---|---|---|

| Definition | Large-scale production of standardized products | Flexible production focused on rapid response to market changes |

| Production Volume | High volume, low variety | Low to medium volume, high variety |

| Flexibility | Low flexibility, fixed processes | High flexibility, adaptable processes |

| Lead Time | Longer lead times due to setup | Short lead times enabled by quick changeovers |

| Cost Structure | Low unit cost via economies of scale | Higher unit cost but reduced inventory costs |

| Product Customization | Minimal to none | High customization capability |

| Technology Utilization | Standardized, dedicated machinery | Advanced, flexible automation and IT systems |

| Supply Chain | Linear, inventory-driven | Integrated, demand-driven with real-time data |

| Market Responsiveness | Slow to adapt | Fast adaptation to market trends |

Understanding Mass Production

Mass production involves the large-scale manufacturing of standardized products using assembly line techniques that maximize efficiency and reduce unit costs. It relies heavily on high-volume output, specialized machinery, and repetitive tasks to achieve economies of scale. This method optimizes production speed and consistency but lacks flexibility to quickly adapt to design changes or customized orders.

Defining Agile Manufacturing

Agile manufacturing is defined as a production approach emphasizing flexibility, rapid response to market changes, and customization tailored to customer demands. It integrates advanced technologies, cross-functional teams, and real-time data to optimize manufacturing processes and improve product quality. Unlike mass production, which prioritizes high volume and uniformity, agile manufacturing focuses on adaptability and minimizing lead times to achieve competitive advantage.

Historical Evolution of Manufacturing Methods

Mass production originated in the early 20th century with Henry Ford's assembly line, revolutionizing manufacturing by enabling large-scale, standardized product output and reducing costs per unit. Agile manufacturing emerged in the late 20th century as a response to rapidly changing market demands, emphasizing flexibility, customization, and quick adaptation through technologies like CAD and flexible automation. The historical evolution from mass production to agile manufacturing reflects a shift from efficiency-driven, uniform processes to customer-centric, responsive production systems.

Key Differences Between Mass Production and Agile Manufacturing

Mass production emphasizes high-volume output with standardized products, utilizing assembly line techniques to minimize per-unit costs and maximize efficiency. Agile manufacturing prioritizes flexibility, enabling rapid adaptation to customer demands and customization while maintaining short lead times through modular processes and cross-functional teams. The core difference lies in mass production's focus on economies of scale versus agile manufacturing's focus on responsiveness and product variety.

Benefits of Mass Production

Mass production offers significant benefits such as economies of scale, which lower per-unit costs by producing large volumes of standardized products. It ensures consistent quality and reliability through highly automated and repetitive processes, minimizing variability. High output rates in mass production enable faster fulfillment of market demand, making it ideal for industries like automotive, electronics, and consumer goods.

Advantages of Agile Manufacturing

Agile manufacturing offers significant advantages by enabling rapid response to market changes and customer demands through flexible production processes and reduced lead times. This approach minimizes inventory costs and enhances customization capabilities, supporting small batch production without sacrificing efficiency. Companies adopting agile manufacturing experience improved innovation and competitiveness by quickly adapting to new technologies and shifting consumer preferences.

Challenges Faced by Each Approach

Mass production encounters challenges such as high inventory costs, inflexibility to market demand changes, and significant setup times for retooling production lines. Agile manufacturing struggles with maintaining consistent quality while rapidly responding to customer customization requests and managing complex supply chains. Both approaches must address balancing efficiency with adaptability to remain competitive in dynamic markets.

Impact on Product Quality and Customization

Mass production emphasizes efficiency and uniformity, often resulting in consistent product quality but limited customization options. Agile manufacturing prioritizes flexibility and rapid response to market changes, enabling higher product customization while maintaining quality through adaptive processes. The trade-off lies in mass production's scale-driven quality control versus agile manufacturing's focus on personalized, high-quality outputs.

Choosing the Right Manufacturing Strategy

Mass production offers economies of scale and cost efficiency for high-demand, standardized products, while agile manufacturing excels in flexibility and rapid response to market changes. Choosing the right manufacturing strategy depends on product complexity, volume requirements, and customer demand volatility. Businesses with stable, high-volume orders benefit from mass production, whereas companies facing frequent design modifications and diverse product lines gain advantages through agile manufacturing.

Future Trends in Manufacturing Practices

Future trends in manufacturing reveal a shift from traditional mass production towards agile manufacturing, emphasizing flexibility, customization, and rapid response to market demands. Advances in digital technologies, such as IoT, AI, and robotics, enable manufacturers to implement agile practices that reduce lead times and improve product variation capabilities. Sustainable manufacturing and smart factories are increasingly prioritizing adaptability, allowing businesses to balance high-volume efficiency with personalized production.

Mass production Infographic

libterm.com

libterm.com