Polymers are large molecules composed of repeating structural units called monomers, which give them unique properties such as flexibility, durability, and resistance to chemicals. Their applications span multiple industries, including packaging, automotive, textiles, and biomedical devices, making them essential in modern manufacturing. Discover more about the types, characteristics, and uses of polymers in the rest of this article.

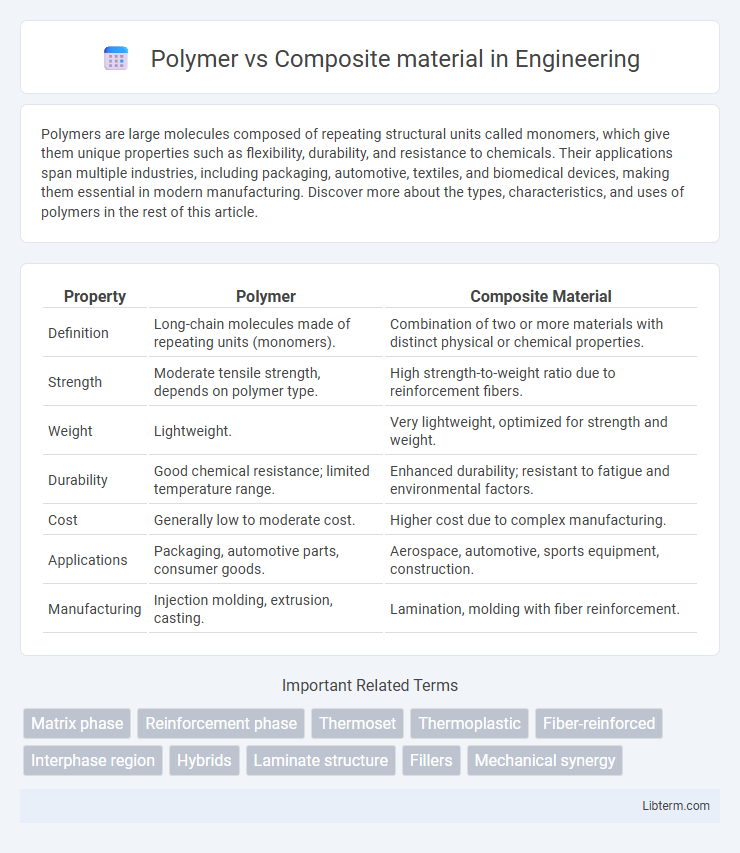

Table of Comparison

| Property | Polymer | Composite Material |

|---|---|---|

| Definition | Long-chain molecules made of repeating units (monomers). | Combination of two or more materials with distinct physical or chemical properties. |

| Strength | Moderate tensile strength, depends on polymer type. | High strength-to-weight ratio due to reinforcement fibers. |

| Weight | Lightweight. | Very lightweight, optimized for strength and weight. |

| Durability | Good chemical resistance; limited temperature range. | Enhanced durability; resistant to fatigue and environmental factors. |

| Cost | Generally low to moderate cost. | Higher cost due to complex manufacturing. |

| Applications | Packaging, automotive parts, consumer goods. | Aerospace, automotive, sports equipment, construction. |

| Manufacturing | Injection molding, extrusion, casting. | Lamination, molding with fiber reinforcement. |

Introduction to Polymers and Composites

Polymers are large molecules composed of repeating structural units called monomers, widely used in industries due to their lightweight, flexibility, and resistance to chemicals. Composite materials combine two or more distinct substances, typically a polymer matrix reinforced with fibers such as glass, carbon, or aramid, to enhance mechanical strength and durability. Understanding the differences between pure polymers and fiber-reinforced composites is crucial for selecting materials in aerospace, automotive, and construction applications.

Defining Polymers: Structure and Properties

Polymers are large molecules composed of repeating structural units called monomers, typically linked by covalent chemical bonds, forming long chains that can be linear, branched, or cross-linked. Their molecular structure directly influences properties such as flexibility, tensile strength, thermal resistance, and chemical stability, making polymers versatile for applications ranging from plastics to elastomers. Common examples include polyethylene, polypropylene, and polyvinyl chloride, each exhibiting distinct characteristics based on polymer chain arrangement and molecular weight.

Understanding Composite Materials

Composite materials consist of two or more constituent materials with significantly different physical or chemical properties, combined to produce a material with characteristics superior to the individual components. Polymers often serve as the matrix phase in composites, binding reinforcement fibers such as carbon, glass, or aramid to provide enhanced strength, stiffness, and durability. Understanding the synergistic behavior of polymers and reinforcements in composites is crucial for applications in aerospace, automotive, and civil engineering where tailored performance is required.

Key Differences Between Polymers and Composites

Polymers consist of long chains of repeating molecular units characterized by their flexibility and lightweight properties, while composites combine two or more distinct materials to achieve enhanced strength, durability, and performance. Polymers exhibit uniform chemical composition and are primarily used for their elasticity and resistance to chemicals, whereas composites leverage the synergistic effects of reinforcement fibers and matrix materials to offer superior mechanical properties. The core difference lies in polymers being single, homogenous materials, whereas composites are engineered systems designed to optimize specific structural or functional characteristics.

Mechanical Properties Comparison

Polymers generally exhibit lower tensile strength and stiffness compared to composites, which combine polymer matrices with reinforcing fibers like carbon or glass to significantly enhance mechanical properties. Composite materials demonstrate superior impact resistance, fatigue strength, and dimensional stability, making them preferable for high-performance structural applications. The anisotropic nature of composites allows tailored strength and stiffness along specific directions, unlike isotropic polymers that have uniform but limited mechanical behavior.

Applications in Various Industries

Polymers find extensive application in industries such as packaging, automotive, and consumer goods due to their lightweight, corrosion resistance, and cost-effectiveness. Composite materials, combining fibers like carbon or glass with polymer matrices, are preferred in aerospace, construction, and sports equipment for their superior strength-to-weight ratio and durability. The aerospace industry heavily relies on composites for structural components, reducing aircraft weight and improving fuel efficiency, while polymers dominate in flexible, moldable products requiring mass production.

Advantages and Disadvantages of Polymers

Polymers offer advantages such as lightweight properties, corrosion resistance, and ease of manufacturing, making them suitable for a wide range of applications including packaging and automotive parts. However, their disadvantages include lower mechanical strength, poor thermal stability, and susceptibility to UV degradation compared to composite materials. While polymers excel in flexibility and cost-effectiveness, they often lack the enhanced durability and stiffness provided by composites reinforced with fibers like carbon or glass.

Advantages and Disadvantages of Composites

Composite materials offer superior strength-to-weight ratios and enhanced corrosion resistance compared to polymers, making them ideal for aerospace and automotive applications where durability and weight reduction are critical. However, composites tend to be more expensive and difficult to repair due to their complex manufacturing processes and anisotropic properties. Their limited recyclability and potential for delamination under stress present additional challenges in sustainability and long-term structural integrity.

Sustainability and Environmental Impact

Polymers often rely on petroleum-based sources, leading to higher carbon footprints and challenges in biodegradability, whereas composites can be engineered from natural fibers and bio-based resins, enhancing sustainability. Composite materials typically offer superior durability and longer lifespan, reducing resource consumption and waste generation over time. Efficient recycling methods for composites are still evolving, but their potential for lightweight design contributes to lower energy use in transportation applications, mitigating environmental impact.

Future Trends in Polymer and Composite Materials

Future trends in polymer and composite materials emphasize enhanced sustainability, including the development of bio-based polymers and recyclable composites to reduce environmental impact. Advanced manufacturing techniques like additive manufacturing and nanotechnology integration are driving improvements in mechanical properties, weight reduction, and multifunctionality. The demand for high-performance composites in aerospace, automotive, and renewable energy sectors is accelerating innovation toward smarter, stronger, and lighter materials capable of withstanding extreme conditions.

Polymer Infographic

libterm.com

libterm.com