Vibration absorption techniques are essential for reducing unwanted oscillations and enhancing stability in mechanical systems. Efficient vibration absorbers improve equipment performance by minimizing noise, wear, and structural damage. Discover how implementing these solutions can protect your machinery and extend its lifespan by reading the rest of the article.

Table of Comparison

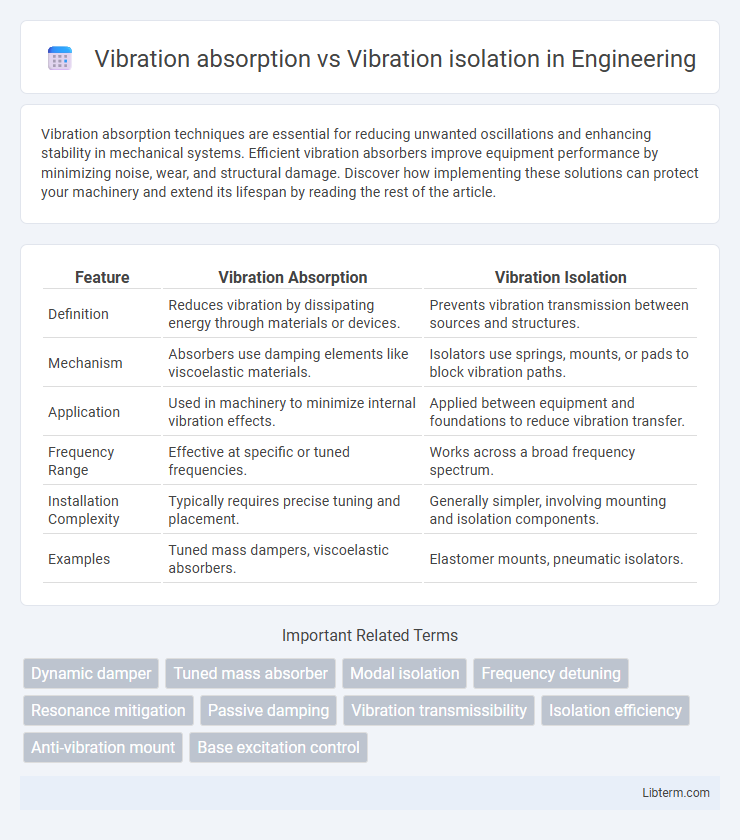

| Feature | Vibration Absorption | Vibration Isolation |

|---|---|---|

| Definition | Reduces vibration by dissipating energy through materials or devices. | Prevents vibration transmission between sources and structures. |

| Mechanism | Absorbers use damping elements like viscoelastic materials. | Isolators use springs, mounts, or pads to block vibration paths. |

| Application | Used in machinery to minimize internal vibration effects. | Applied between equipment and foundations to reduce vibration transfer. |

| Frequency Range | Effective at specific or tuned frequencies. | Works across a broad frequency spectrum. |

| Installation Complexity | Typically requires precise tuning and placement. | Generally simpler, involving mounting and isolation components. |

| Examples | Tuned mass dampers, viscoelastic absorbers. | Elastomer mounts, pneumatic isolators. |

Introduction to Vibration Control

Vibration absorption and vibration isolation are critical techniques in vibration control that enhance machinery performance and prolong equipment life. Vibration absorption involves dissipating energy through materials or devices like dampers to reduce amplitude, while vibration isolation uses barriers or mounts to prevent transmission of vibrations to surrounding structures. Effective vibration control mitigates noise, minimizes wear, and ensures operational stability in industrial and mechanical systems.

Defining Vibration Absorption

Vibration absorption involves converting vibrational energy into other forms, such as heat, using materials or devices like dampers to reduce the amplitude of vibrations. This process specifically targets the internal dissipation of energy within a system, contrasting with vibration isolation, which prevents vibration transmission by physically separating or decoupling the source from the supported structure. Efficient vibration absorbers are critical in applications requiring the attenuation of specific frequency ranges to protect sensitive equipment and ensure operational stability.

Understanding Vibration Isolation

Vibration isolation involves techniques and materials designed to prevent the transmission of vibrations from one structure to another, ensuring sensitive equipment operates without disturbance. This method uses isolators such as rubber mounts, springs, or pneumatic systems that absorb and redirect vibrational energy away from critical components. Effective vibration isolation enhances machinery lifespan, improves precision in measurement instruments, and reduces noise pollution in industrial settings.

Key Differences Between Absorption and Isolation

Vibration absorption involves converting vibration energy into another form, usually heat, to reduce amplitude within the system, while vibration isolation prevents the transmission of vibration from one structure to another through barriers or dampers. Absorption materials typically exhibit viscoelastic properties that dissipate energy, whereas isolation relies on mechanical decoupling using springs, mounts, or pads to block vibration paths. Key differences include the mechanism of action--energy dissipation versus energy blocking--and their application scope, with absorption suited for internal damping and isolation focused on protecting sensitive equipment from external vibrations.

Applications of Vibration Absorption

Vibration absorption is widely applied in mechanical systems and structural engineering to reduce resonant vibrations by using tuned mass dampers that counteract specific frequencies, enhancing stability and longevity of machinery. Key applications include automotive suspensions, aerospace structures, and building frameworks where precise vibration control minimizes wear and improves comfort. Compared to vibration isolation, which prevents transmission of vibrations by decoupling, vibration absorption actively dissipates energy within the system, making it ideal for environments with predictable vibrational frequencies.

Common Uses of Vibration Isolation

Vibration isolation is commonly used in industrial machinery, HVAC systems, and building foundations to prevent the transmission of vibrations to surrounding structures, enhancing equipment longevity and reducing noise pollution. It employs materials like elastomers, springs, or air mounts to decouple equipment from vibration sources, effectively protecting sensitive instruments and maintaining structural integrity. In contrast, vibration absorption focuses on dissipating vibrational energy within the system itself rather than preventing its transmission.

Material Selection for Absorption and Isolation

Material selection for vibration absorption emphasizes viscoelastic materials such as natural rubber, silicone, and polyurethane due to their ability to dissipate vibrational energy as heat. In contrast, vibration isolation relies on materials with high damping properties and low stiffness, including neoprene and elastomers, to prevent vibration transmission by decoupling the source and the structure. Engineers choose absorption materials to reduce vibration amplitude within systems, while isolation materials are selected to minimize the propagation of vibrations to sensitive equipment or structural components.

Performance Comparison: Absorption vs Isolation

Vibration absorption effectively reduces vibrational energy by converting it into heat, providing targeted damping mainly in specific frequency ranges, while vibration isolation prevents transmission by decoupling the source from the receiver with resilient materials or mounts. Absorbers excel in improving performance for systems with predictable, narrow-frequency vibrations but may lose efficiency under variable conditions, whereas isolators deliver broad-spectrum attenuation, maintaining consistent vibration reduction across multiple frequencies. Choosing between absorption and isolation depends on the application's frequency range, amplitude, and structural constraints, with absorption favoring controlled environments and isolation suited for unpredictable or wideband vibration scenarios.

Cost Considerations in Vibration Control

Vibration absorption typically involves materials or devices that dissipate vibrational energy, often requiring maintenance or replacement, influencing long-term expenses. Vibration isolation focuses on preventing vibrational transmission through mounts or isolators, which may have higher initial costs but lower ongoing expenses. Selecting between them depends on budget constraints, expected lifespan, and specific application requirements for cost-effective vibration control.

Choosing the Right Solution for Your Application

Vibration absorption involves dissipating vibrational energy within a material or device, making it ideal for applications requiring reduction of specific frequencies or resonance control. Vibration isolation prevents the transmission of vibrations from one system to another, best suited for protecting sensitive equipment or structures from external vibrational sources. Selecting the right solution depends on factors such as frequency range, system sensitivity, load characteristics, and environmental conditions to ensure optimal performance and longevity.

Vibration absorption Infographic

libterm.com

libterm.com