Electron beam melting (EBM) is an advanced additive manufacturing technique that uses a focused electron beam to selectively melt metal powders layer by layer, producing high-density and complex metal parts with excellent mechanical properties. This process operates in a vacuum, minimizing oxidation and contamination, making it ideal for aerospace, medical implants, and customized engineering applications. Discover how EBM can transform your manufacturing capabilities and explore its benefits in the rest of this article.

Table of Comparison

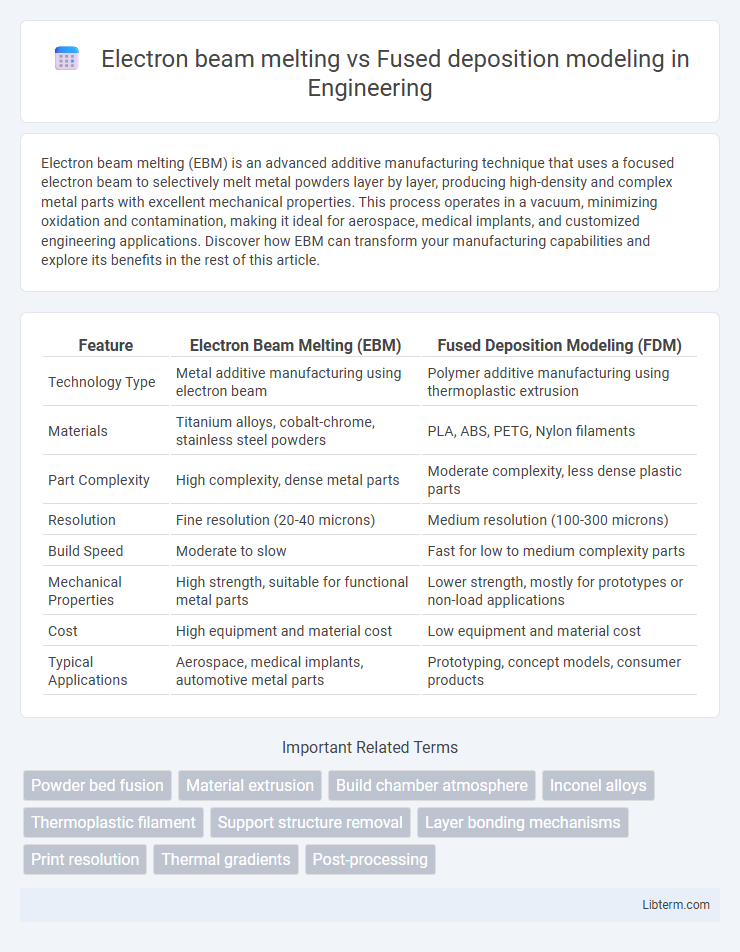

| Feature | Electron Beam Melting (EBM) | Fused Deposition Modeling (FDM) |

|---|---|---|

| Technology Type | Metal additive manufacturing using electron beam | Polymer additive manufacturing using thermoplastic extrusion |

| Materials | Titanium alloys, cobalt-chrome, stainless steel powders | PLA, ABS, PETG, Nylon filaments |

| Part Complexity | High complexity, dense metal parts | Moderate complexity, less dense plastic parts |

| Resolution | Fine resolution (20-40 microns) | Medium resolution (100-300 microns) |

| Build Speed | Moderate to slow | Fast for low to medium complexity parts |

| Mechanical Properties | High strength, suitable for functional metal parts | Lower strength, mostly for prototypes or non-load applications |

| Cost | High equipment and material cost | Low equipment and material cost |

| Typical Applications | Aerospace, medical implants, automotive metal parts | Prototyping, concept models, consumer products |

Introduction to Electron Beam Melting and Fused Deposition Modeling

Electron Beam Melting (EBM) utilizes a high-energy electron beam to selectively melt metal powder layer by layer in a vacuum environment, enabling the production of dense, complex metal parts with excellent mechanical properties. Fused Deposition Modeling (FDM) is an additive manufacturing process that extrudes thermoplastic filaments through a heated nozzle, building parts layer by layer with precision and cost-effectiveness for prototypes and functional components. EBM excels in aerospace and medical implant applications due to its superior material characteristics, while FDM is widely used for rapid prototyping and low-cost end-use parts.

Technology Overview: EBM vs FDM

Electron beam melting (EBM) utilizes a high-energy electron beam to selectively melt metal powders layer by layer in a vacuum environment, achieving fully dense metal parts ideal for aerospace and medical implants. Fused deposition modeling (FDM) extrudes thermoplastic filaments through a heated nozzle, building parts layer by layer with lower resolution and mechanical strength primarily suited for prototyping and low-stress applications. EBM provides superior metallurgical properties and surface finish, while FDM offers cost-effectiveness and simplicity for rapid prototyping.

Materials Used in EBM and FDM

Electron beam melting (EBM) primarily uses metal powders such as titanium alloys, cobalt-chrome, and stainless steel, enabling the production of dense, high-strength metal parts ideal for aerospace and medical implants. In contrast, fused deposition modeling (FDM) utilizes thermoplastic polymers like ABS, PLA, and nylon, which are extruded layer by layer to create components suitable for prototyping and low-strength applications. The material choice in EBM ensures superior mechanical properties and thermal resilience, while FDM materials offer versatility, cost-effectiveness, and ease of printing.

Process Workflow Comparison

Electron beam melting (EBM) involves melting metal powder layer by layer using an electron beam in a high vacuum environment, enabling the fabrication of complex, high-strength metal parts with excellent mechanical properties. Fused deposition modeling (FDM) extrudes thermoplastic filament through a heated nozzle, depositing it layer by layer to build prototypes and functional parts with moderate strength and surface finish. EBM requires preheating, rapid melting, and post-processing in controlled atmospheres, while FDM operates at lower temperatures with straightforward layer fusion, resulting in faster setup but less material diversity and precision.

Surface Finish and Dimensional Accuracy

Electron beam melting (EBM) produces parts with superior surface finish characterized by a slightly rough texture due to the powder bed process, but it generally offers enhanced dimensional accuracy for complex metal components compared to fused deposition modeling (FDM). FDM often results in visible layer lines and rougher surfaces because of the extrusion of thermoplastic filaments, which limits surface smoothness without post-processing. Dimensional accuracy in FDM is affected by material shrinkage and warping, making EBM a preferred choice for precise, functional metal parts requiring tight tolerances.

Mechanical Properties of Printed Parts

Electron beam melting (EBM) produces printed parts with superior mechanical properties, including higher tensile strength and better fatigue resistance, due to its ability to fully melt metal powders and create dense, homogenous structures. Fused deposition modeling (FDM) parts typically exhibit lower mechanical strength and can suffer from anisotropy and layer adhesion issues, which reduce overall durability and impact resistance. The choice of technique significantly affects the mechanical performance of printed components, with EBM favored for critical aerospace and medical applications requiring robust metal parts.

Applications and Industry Adoption

Electron beam melting (EBM) is predominantly utilized in aerospace, medical implants, and high-performance engineering sectors due to its ability to produce dense, high-strength metal parts such as titanium alloys. Fused deposition modeling (FDM) is widely adopted in prototyping, automotive, and consumer goods industries for cost-effective, rapid production of polymer parts and functional prototypes. The higher material and equipment costs limit EBM mainly to specialized applications, while FDM's accessibility supports broader industry adoption and diverse material usage.

Cost Considerations: EBM vs FDM

Electron Beam Melting (EBM) typically incurs higher costs compared to Fused Deposition Modeling (FDM) due to expensive equipment, specialized materials, and energy-intensive processes. FDM benefits from lower initial investment and operational expenses, making it more accessible for prototyping and small-scale production. The cost-effectiveness of FDM is often favored in applications where budget constraints outweigh the precision and material properties offered by EBM.

Advantages and Limitations

Electron beam melting (EBM) offers high precision and superior mechanical properties by using a high-energy electron beam to melt metal powders layer by layer, making it ideal for complex, high-strength metal parts. It excels in producing fully dense metal components with excellent surface finish and reduced residual stress but is limited by high equipment costs and slower production rates compared to Fused Deposition Modeling (FDM). FDM, on the other hand, utilizes thermoplastic filaments and is cost-effective, quick, and widely accessible, but it often results in lower resolution, weaker mechanical strength, and less material versatility compared to EBM.

Future Trends in EBM and FDM Technologies

Future trends in Electron Beam Melting (EBM) emphasize enhanced material properties and faster build rates through advanced beam control and in-situ monitoring systems. Fused Deposition Modeling (FDM) is evolving with multi-material capabilities and improved thermoplastic composites to broaden functional applications and mechanical performance. Both technologies are trending toward greater automation, integration with AI-driven process optimization, and sustainability via recycled feedstock utilization.

Electron beam melting Infographic

libterm.com

libterm.com