Mean Time Between Failures (MTBF) measures the average time a system operates before experiencing a failure, providing critical insight into reliability and maintenance schedules. Understanding MTBF helps you anticipate downtime, optimize operational efficiency, and plan preventive maintenance to extend equipment lifespan. Explore the rest of this article to learn how MTBF impacts system performance and how to calculate it effectively.

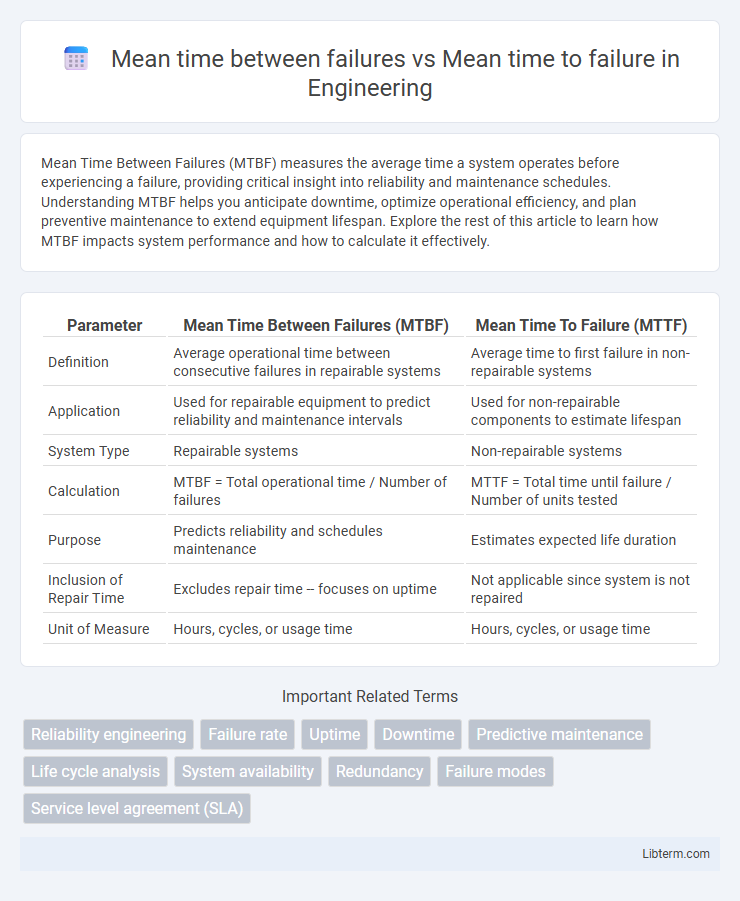

Table of Comparison

| Parameter | Mean Time Between Failures (MTBF) | Mean Time To Failure (MTTF) |

|---|---|---|

| Definition | Average operational time between consecutive failures in repairable systems | Average time to first failure in non-repairable systems |

| Application | Used for repairable equipment to predict reliability and maintenance intervals | Used for non-repairable components to estimate lifespan |

| System Type | Repairable systems | Non-repairable systems |

| Calculation | MTBF = Total operational time / Number of failures | MTTF = Total time until failure / Number of units tested |

| Purpose | Predicts reliability and schedules maintenance | Estimates expected life duration |

| Inclusion of Repair Time | Excludes repair time -- focuses on uptime | Not applicable since system is not repaired |

| Unit of Measure | Hours, cycles, or usage time | Hours, cycles, or usage time |

Introduction to MTBF and MTTF

Mean Time Between Failures (MTBF) measures the average operational time between system breakdowns, indicating reliability for repairable systems. Mean Time To Failure (MTTF) represents the expected lifespan of non-repairable components until failure occurs. Understanding MTBF and MTTF helps optimize maintenance schedules and improve system design by predicting failure intervals and component durability.

Defining Mean Time Between Failures (MTBF)

Mean Time Between Failures (MTBF) measures the average operational time between inherent system breakdowns, serving as a key reliability metric for repairable systems. MTBF is calculated by dividing total operational hours by the number of failures, providing insight into system durability and maintenance scheduling. Unlike Mean Time To Failure (MTTF), which applies to non-repairable components and represents expected operating lifespan before failure, MTBF emphasizes system availability and maintainability.

Defining Mean Time To Failure (MTTF)

Mean Time To Failure (MTTF) measures the average operational time of a non-repairable system or component before it fails, providing a key reliability indicator. It differs from Mean Time Between Failures (MTBF), which applies to repairable systems and includes both operational and repair times. MTTF helps engineers estimate product lifespan and plan maintenance schedules for single-use devices or components.

Key Differences Between MTBF and MTTF

Mean Time Between Failures (MTBF) represents the average time between consecutive failures in repairable systems, indicating system reliability and maintenance intervals. Mean Time To Failure (MTTF) measures the average operational time before a non-repairable system or component fails, reflecting the expected lifespan. Key differences include MTBF applying to repairable equipment with multiple failure cycles, while MTTF applies to non-repairable items with a single failure event.

Importance of MTBF and MTTF in Reliability Engineering

Mean Time Between Failures (MTBF) quantifies the average operational time between system breakdowns, serving as a critical indicator of equipment reliability in maintainability-focused contexts. Mean Time To Failure (MTTF) measures the expected lifespan of a non-repairable component until failure, guiding design decisions and warranty analysis in reliability engineering. Both MTBF and MTTF provide essential metrics for predicting system performance, optimizing maintenance schedules, and minimizing downtime in industrial applications.

How to Calculate MTBF and MTTF

Mean Time Between Failures (MTBF) is calculated by dividing the total operational time by the number of failures during that period, typically used for repairable systems. Mean Time To Failure (MTTF) is calculated by totaling the operational time of non-repairable items until failure and dividing by the number of units, highlighting the average life span before failure. Accurate calculation of MTBF and MTTF requires comprehensive failure data and consistent monitoring of system operation times for reliability analysis.

Practical Applications in Industry

Mean Time Between Failures (MTBF) is critical for planning maintenance schedules in manufacturing, as it estimates the average operational time between inherent failures of equipment, helping reduce downtime. Mean Time To Failure (MTTF) is primarily used for non-repairable systems, providing a benchmark for product lifespan and warranty analysis in industries like electronics and automotive. Both metrics support reliability engineering by guiding inventory management, resource allocation, and risk assessment in industrial operations.

Factors Influencing MTBF and MTTF

Mean Time Between Failures (MTBF) measures the average time between system breakdowns during operation, while Mean Time To Failure (MTTF) indicates the expected lifespan before a non-repairable component fails. Factors influencing MTBF include operational conditions, maintenance practices, and component quality, whereas MTTF is primarily affected by material properties, manufacturing defects, and environmental stressors. Both metrics are critical for reliability engineering but differ in their application based on whether the system is repairable or non-repairable.

Common Mistakes and Misconceptions

Mean Time Between Failures (MTBF) is often confused with Mean Time To Failure (MTTF), yet MTBF measures the average time between repairs for repairable systems, while MTTF applies to non-repairable items until failure. A common mistake is using MTBF to predict the lifespan of non-repairable equipment, leading to inaccurate reliability assessments. Misconceptions also arise when MTBF is interpreted as the exact life expectancy, ignoring the statistical nature and variability inherent in failure data.

Choosing the Right Metric for Your System

Mean Time Between Failures (MTBF) measures the average time between system failures, ideal for repairable systems to assess reliability and maintenance schedules. Mean Time To Failure (MTTF) calculates the expected lifespan before the first failure, best suited for non-repairable components to predict product durability. Selecting the right metric depends on whether the system is maintainable or disposable, with MTBF guiding maintenance planning and MTTF informing product design and warranty considerations.

Mean time between failures Infographic

libterm.com

libterm.com