Square thread features a 90-degree thread profile, offering superior efficiency and strength compared to trapezoidal or V-threads. Commonly used in power transmission applications such as lead screws, its design minimizes friction and wear for smoother movement and longer lifespan. Discover how square threads can enhance your mechanical projects in the rest of this article.

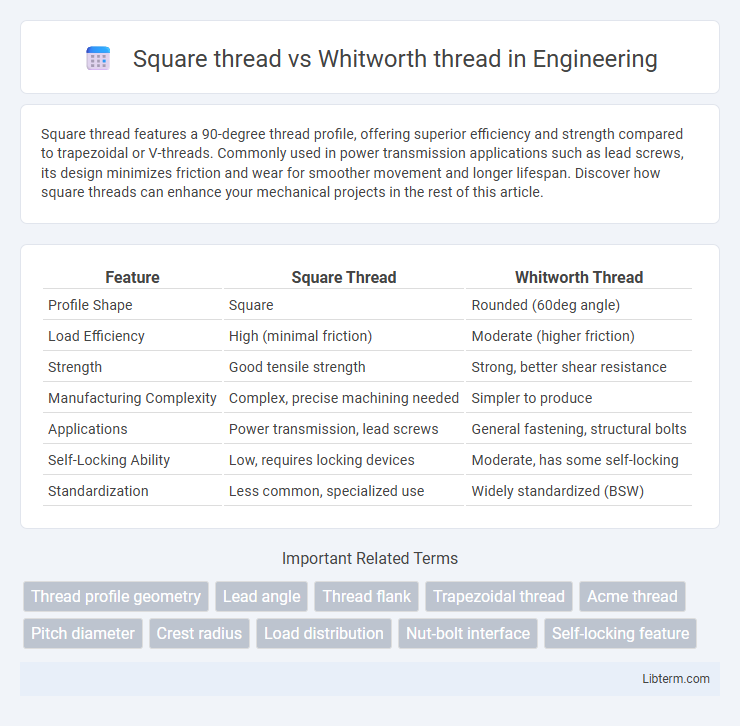

Table of Comparison

| Feature | Square Thread | Whitworth Thread |

|---|---|---|

| Profile Shape | Square | Rounded (60deg angle) |

| Load Efficiency | High (minimal friction) | Moderate (higher friction) |

| Strength | Good tensile strength | Strong, better shear resistance |

| Manufacturing Complexity | Complex, precise machining needed | Simpler to produce |

| Applications | Power transmission, lead screws | General fastening, structural bolts |

| Self-Locking Ability | Low, requires locking devices | Moderate, has some self-locking |

| Standardization | Less common, specialized use | Widely standardized (BSW) |

Introduction to Thread Types

Square threads feature a profile with flat crests and roots, primarily designed for power transmission and high-load applications due to their low friction and efficient load distribution. Whitworth threads have a rounded profile with a 55-degree angle, commonly used for general fastening purposes, offering ease of manufacturing and good strength. The choice between square and Whitworth threads depends on the application's requirements for load capacity, precision, and manufacturing complexity.

Overview of Square Threads

Square threads feature a thread profile with a square-shaped cross-section designed to provide high efficiency and minimal friction in power transmission applications. They are commonly used in lead screws, jacks, and presses due to their capability to handle heavy loads and resist wear. Compared to Whitworth threads, square threads offer better strength and durability but are more challenging to manufacture and less suitable for general fastening purposes.

Overview of Whitworth Threads

Whitworth threads, established by Sir Joseph Whitworth in 1841, are characterized by a thread angle of 55 degrees and rounded crests and roots, offering robust strength and resistance to stress concentration. Widely used in British Standard Pipe (BSP) fittings and older machinery, Whitworth threads provide reliable sealing in fluid and gas applications due to their precise thread geometry. The design prioritizes ease of manufacturing and compatibility across various industrial sectors, making Whitworth threads a longstanding standard in mechanical engineering.

Design Differences: Square vs Whitworth

Square threads feature a thread profile with a flat crest and root, providing high efficiency and strength for power transmission applications. Whitworth threads have a rounded thread profile with a 55-degree angle, designed for general fastening purposes with improved load distribution. The distinct geometric differences between square and Whitworth threads influence their suitability, with square threads excelling in minimizing friction and Whitworth threads offering better resistance to wear and easier manufacturing.

Strength and Load Capacity Comparison

Square threads exhibit superior strength and load capacity compared to Whitworth threads due to their nearly perpendicular thread profile, which distributes shear forces evenly along the thread flanks. Whitworth threads, featuring an angled 55-degree thread form, experience higher stress concentrations that reduce their load-bearing efficiency under heavy mechanical loads. Consequently, square threads are preferred in power transmission applications where maximum load capacity and durability are critical.

Applications and Use Cases

Square threads are primarily used in applications demanding high efficiency and power transmission, such as lead screws in machine tools, jacks, and presses due to their low friction and high load-carrying capacity. Whitworth threads find widespread use in fastening and general engineering tasks, particularly in British standard screw threads for pipes, bolts, and nuts, where moderate strength and ease of manufacturing are essential. The choice between Square and Whitworth threads depends on the need for precise linear motion control versus general-purpose fastening and mechanical assembly.

Manufacturing and Machining Considerations

Square threads offer superior efficiency in power transmission and lower friction, but their manufacturing requires precise machinery and is more complex due to the thread's geometry, making them challenging to cut and grind. Whitworth threads, featuring a 55-degree thread angle with rounded roots, are easier to manufacture and machine using standard tools, providing better strength and resistance to stress concentrations in general fastening applications. The choice depends on balancing manufacturing complexity with functional requirements, where square threads demand advanced tooling for accurate production, while Whitworth threads accommodate simpler, cost-effective machining processes.

Advantages of Square Threads

Square threads offer superior efficiency compared to Whitworth threads due to their low friction and high torque transmission capabilities. Their profile design minimizes radial pressure on nut walls, reducing wear and enhancing longevity in power transmission applications. These characteristics make square threads ideal for linear motion devices such as lead screws and jacks requiring precise, smooth operation.

Advantages of Whitworth Threads

Whitworth threads offer superior load distribution due to their rounded thread profile, reducing stress concentration and increasing joint durability in heavy-duty applications. Their standardized 55-degree thread angle improves resistance to wear and facilitates smoother assembly and disassembly compared to square threads. Whitworth threads also provide better sealing capabilities, making them ideal for applications requiring airtight or fluid-tight connections.

Choosing the Right Thread for Your Project

Selecting between square thread and Whitworth thread depends on the application's load requirements and precision. Square threads offer high efficiency and minimal friction, ideal for power transmission and heavy-duty applications, while Whitworth threads provide strong, all-purpose fastening with a rounded profile suitable for general assembly and ease of manufacturing. Evaluate factors like load capacity, wear resistance, and machining complexity to determine the optimal thread type for project success.

Square thread Infographic

libterm.com

libterm.com