Welding is a critical fabrication process that joins materials, usually metals or thermoplastics, by applying intense heat to melt the parts together. This technique is essential in construction, manufacturing, and repairs, ensuring strong and durable connections. Explore the article to understand how welding can enhance your projects with precision and strength.

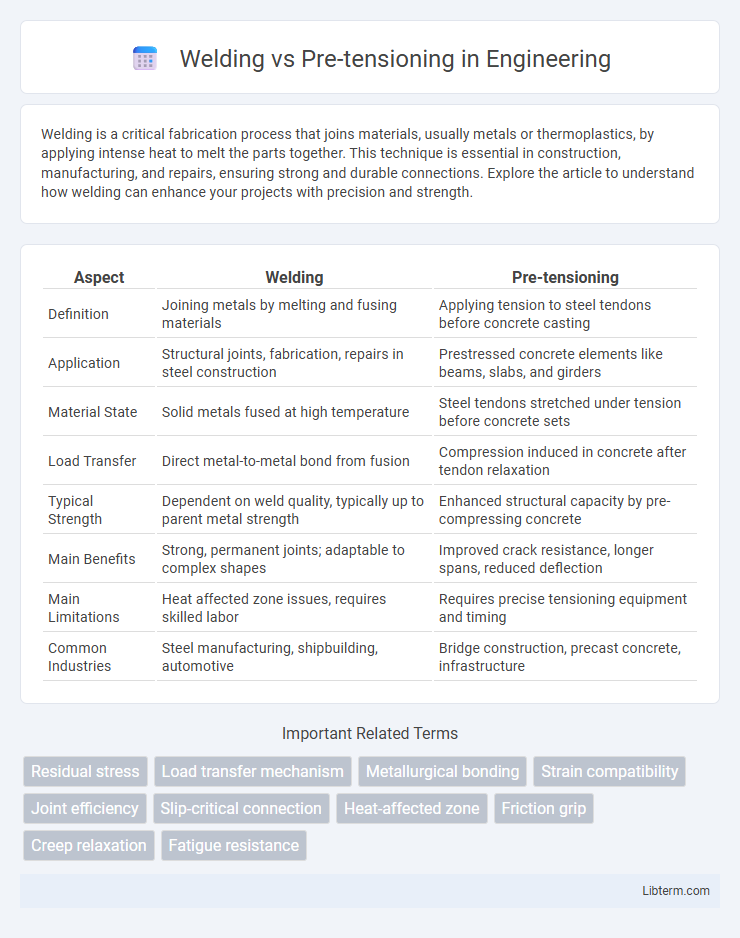

Table of Comparison

| Aspect | Welding | Pre-tensioning |

|---|---|---|

| Definition | Joining metals by melting and fusing materials | Applying tension to steel tendons before concrete casting |

| Application | Structural joints, fabrication, repairs in steel construction | Prestressed concrete elements like beams, slabs, and girders |

| Material State | Solid metals fused at high temperature | Steel tendons stretched under tension before concrete sets |

| Load Transfer | Direct metal-to-metal bond from fusion | Compression induced in concrete after tendon relaxation |

| Typical Strength | Dependent on weld quality, typically up to parent metal strength | Enhanced structural capacity by pre-compressing concrete |

| Main Benefits | Strong, permanent joints; adaptable to complex shapes | Improved crack resistance, longer spans, reduced deflection |

| Main Limitations | Heat affected zone issues, requires skilled labor | Requires precise tensioning equipment and timing |

| Common Industries | Steel manufacturing, shipbuilding, automotive | Bridge construction, precast concrete, infrastructure |

Introduction to Welding and Pre-tensioning

Welding is a fabrication process that joins materials, primarily metals, by causing coalescence through heat, pressure, or both, creating strong, permanent joints used in construction and manufacturing. Pre-tensioning involves applying tensile force to steel tendons before concrete casting, enhancing structural strength and controlling stress distribution in pre-stressed concrete elements. Both techniques are essential in structural engineering but serve different purposes, with welding focusing on joining components and pre-tensioning improving load-bearing capacity.

Key Differences Between Welding and Pre-tensioning

Welding involves joining metal parts by melting their surfaces to create a strong, permanent bond, while pre-tensioning applies tensile force to steel tendons before concrete is cast to enhance structural strength. Welding is primarily used for fabricating and repairing metal components, whereas pre-tensioning is a technique in prestressed concrete to control cracks and improve load-bearing capacity. Key differences include the application method--heat and fusion for welding versus mechanical tensioning for pre-tensioning--and the materials affected, with welding targeting metals and pre-tensioning focusing on concrete reinforcement.

Core Principles of Welding

Welding involves the fusion of materials, typically metals or thermoplastics, by applying heat, pressure, or both to create a strong joint at the molecular level. The core principles of welding include proper selection of welding methods such as MIG, TIG, or arc welding, control of heat input to avoid distortions, and ensuring compatibility of filler materials with base metals. Welding emphasizes metallurgical bonding, requiring skilled manipulation of temperature and environment to achieve structural integrity and resistance to mechanical stress.

Fundamental Concepts of Pre-tensioning

Pre-tensioning involves applying a tensile force to steel tendons before concrete casting, enhancing structural strength and durability through controlled stress distribution. Unlike welding, which relies on heat to join metal components, pre-tensioning leverages the elastic properties of steel to induce compressive stress in concrete, reducing cracking and increasing load-bearing capacity. This fundamental concept is crucial in prestressed concrete applications, enabling optimized performance in bridges, beams, and other infrastructure elements.

Material Suitability: Welding vs Pre-tensioning

Welding is ideal for materials with high ductility, such as mild steel and stainless steel, allowing strong, permanent joints through localized melting and fusion. Pre-tensioning suits materials like high-strength steel strands or cables, which benefit from tensile stress applied before loading to enhance performance and crack resistance. Material suitability depends on thermal sensitivity, strength requirements, and structural application, influencing the choice between welding and pre-tensioning techniques.

Structural Applications and Use Cases

Welding provides a permanent joint ideal for connecting steel components in structural applications such as building frameworks and bridge construction, offering high strength and rigidity. Pre-tensioning enhances concrete elements by applying tension to steel tendons before concrete curing, improving load-bearing capacity and resistance to tensile stresses in applications like prestressed concrete beams and slabs. Structural engineers select welding for metal assemblies requiring seamless integration, while pre-tensioning is preferred for concrete infrastructures needing enhanced durability and crack control.

Advantages of Welding

Welding offers a permanent, strong bond by fusing metals at high temperatures, ensuring structural integrity in critical applications. It allows for versatile design flexibility and seamless connections without the need for additional components such as bolts or anchors. Compared to pre-tensioning, welding provides enhanced resistance to dynamic loads and reduces the risk of loosening under vibration or stress.

Advantages of Pre-tensioning

Pre-tensioning offers superior load distribution and enhanced structural integrity by applying tensile forces before external loads are applied, reducing the risk of cracks and improving durability in concrete elements. It allows for precise control over stress levels, resulting in higher efficiency and longer service life compared to welding, which can introduce heat-affected zones and potential weaknesses. Pre-tensioning also minimizes material fatigue and maintenance needs, making it ideal for bridges, beams, and other critical infrastructure requiring long-term reliability.

Limitations and Challenges

Welding faces limitations such as heat distortion, residual stresses, and difficulty in joining certain materials like high-strength steels or aluminum alloys, which can compromise joint integrity. Pre-tensioning challenges include the need for precise control of stress levels, potential relaxation over time, and complex installation procedures requiring specialized equipment and expertise. Both methods demand careful consideration of material properties and environmental factors to ensure structural performance and durability.

Choosing the Right Method: Welding or Pre-tensioning

Choosing the right method between welding and pre-tensioning depends on the specific structural requirements and material characteristics. Welding provides strong, permanent joints ideal for steel fabrication, while pre-tensioning enhances concrete's load-bearing capacity by applying controlled stress before external loads. Consider factors such as load type, environmental conditions, and project scale to determine the most effective approach for durability and performance.

Welding Infographic

libterm.com

libterm.com