Poisson's ratio measures the ratio of transverse strain to axial strain in a material under stress, reflecting how it deforms in directions perpendicular to the applied force. This property is crucial in engineering and materials science for predicting material behavior and ensuring structural integrity. Explore this article to understand how Poisson's ratio influences your designs and material selection.

Table of Comparison

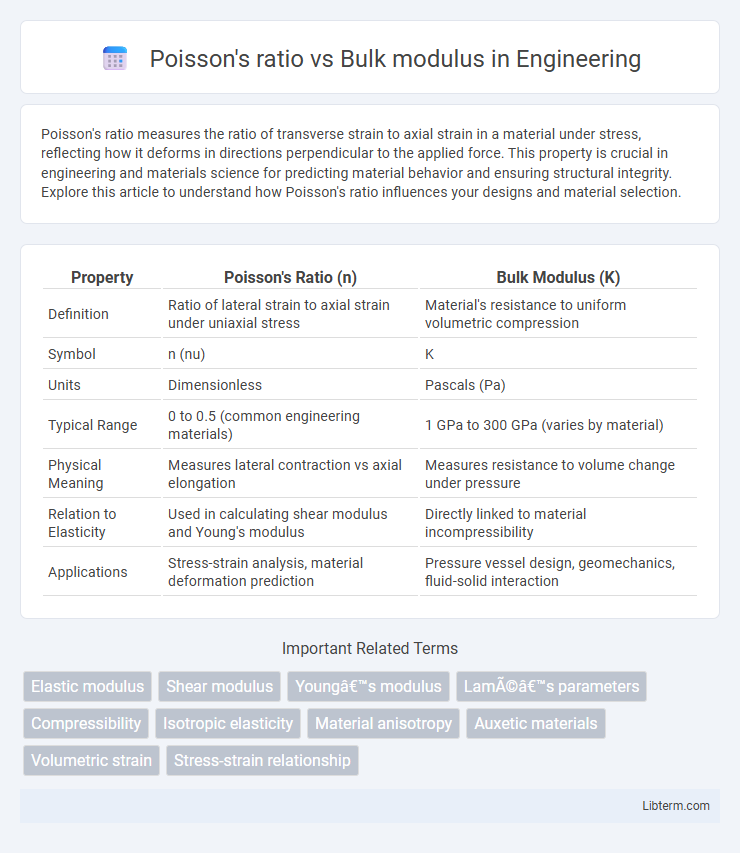

| Property | Poisson's Ratio (n) | Bulk Modulus (K) |

|---|---|---|

| Definition | Ratio of lateral strain to axial strain under uniaxial stress | Material's resistance to uniform volumetric compression |

| Symbol | n (nu) | K |

| Units | Dimensionless | Pascals (Pa) |

| Typical Range | 0 to 0.5 (common engineering materials) | 1 GPa to 300 GPa (varies by material) |

| Physical Meaning | Measures lateral contraction vs axial elongation | Measures resistance to volume change under pressure |

| Relation to Elasticity | Used in calculating shear modulus and Young's modulus | Directly linked to material incompressibility |

| Applications | Stress-strain analysis, material deformation prediction | Pressure vessel design, geomechanics, fluid-solid interaction |

Introduction to Poisson's Ratio and Bulk Modulus

Poisson's ratio quantifies the lateral strain to axial strain ratio under uniaxial stress, typically ranging between 0 and 0.5 for most materials, indicating volumetric stability during deformation. Bulk modulus measures a material's resistance to uniform compression, representing the ratio of applied pressure to fractional volume decrease. Both parameters are fundamental in characterizing elastic properties and are interrelated through elastodynamic equations governing isotropic materials.

Definitions: Understanding Poisson's Ratio

Poisson's ratio measures the lateral strain to axial strain ratio in a material subjected to uniaxial stress, indicating how much a material becomes thinner in cross-section when stretched. The bulk modulus quantifies a material's resistance to uniform compression, representing the ratio of volumetric stress to volumetric strain. Understanding Poisson's ratio helps predict dimensional changes under stress, while the bulk modulus relates to volumetric elasticity, both essential in material science and engineering applications.

Exploring Bulk Modulus: Meaning and Formula

Bulk modulus measures a material's resistance to uniform compression and is defined as the ratio of applied pressure to the resulting volumetric strain. It is mathematically expressed as \( K = -V \frac{dP}{dV} \), where \( K \) is the bulk modulus, \( P \) is pressure, and \( V \) is volume. Poisson's ratio influences the relationship between bulk modulus and other elastic constants, linking lateral strain to axial strain under stress.

Physical Significance of Poisson's Ratio

Poisson's ratio quantifies the lateral contraction of a material when subjected to axial stretching, providing insight into its deformation behavior under stress. It indicates the relative change in transverse strain to axial strain, which helps characterize the material's ductility and volumetric changes. While bulk modulus measures a material's resistance to uniform compression, Poisson's ratio complements this by describing how the shape of the material changes during loading, essential for predicting mechanical performance in engineering applications.

Bulk Modulus: Importance in Material Science

Bulk modulus, a fundamental mechanical property, quantifies a material's resistance to uniform compression, influencing its ability to withstand pressure without volume change. Unlike Poisson's ratio, which measures the transverse strain response to axial stress, bulk modulus directly relates to volumetric elasticity critical in designing materials for high-pressure environments. This parameter is essential for applications in geophysics, aerospace, and structural engineering, where understanding compressibility governs material selection and performance optimization.

Mathematical Relationship Between Poisson's Ratio and Bulk Modulus

Poisson's ratio (n) and Bulk modulus (K) are related through the elastic constants of isotropic materials by the equation K = E / [3(1 - 2n)], where E is the Young's modulus. This relationship highlights that as Poisson's ratio approaches 0.5, indicating near-incompressibility, the bulk modulus tends to infinity, reflecting increasing resistance to volume change under pressure. Understanding this mathematical connection is crucial for predicting material behavior under mechanical stress in fields like materials science and mechanical engineering.

Comparison: Mechanical Implications of Poisson's Ratio vs Bulk Modulus

Poisson's ratio and bulk modulus both characterize material deformation under stress but differ in mechanical implications; Poisson's ratio measures lateral strain to axial strain ratio, indicating ductility and volumetric change, while bulk modulus quantifies resistance to uniform compression, reflecting material incompressibility. Higher Poisson's ratio values imply greater transverse expansion, affecting shear behavior, whereas a larger bulk modulus denotes stiffer materials resisting volume change under pressure. Engineers use Poisson's ratio for predicting shape changes and failure modes, while bulk modulus is critical for applications involving fluid pressure and material compaction.

Applications: Where Poisson's Ratio and Bulk Modulus Matter

Poisson's ratio is critical in structural engineering for determining material deformation under stress, influencing the design of bridges, buildings, and aerospace components to ensure stability and durability. Bulk modulus plays a vital role in geophysics and material science by describing a material's resistance to uniform compression, essential for modeling seismic wave propagation and designing pressure-resistant vessels. Both parameters are pivotal in biomechanics to simulate tissue elasticity and in manufacturing, where precise material selection impacts product performance under mechanical loads.

Factors Affecting Both Properties in Materials

Poisson's ratio and bulk modulus are influenced by atomic bonding strength, crystal structure, and temperature within materials. Variations in bonding type, such as ionic, covalent, or metallic bonds, alter the material's resistance to volumetric deformation and lateral strain, directly impacting both properties. Microstructural features like grain size and phase distribution also play a crucial role in modifying the bulk modulus and Poisson's ratio by affecting elastic response under stress.

Summary: Key Differences and Interdependence

Poisson's ratio quantifies the lateral strain response of a material to axial stress, typically ranging from 0 to 0.5 in most solids, while the bulk modulus measures a material's resistance to uniform compression, expressed in units of pressure such as gigapascals. These parameters are interrelated through elastic modulus values, where a higher bulk modulus often corresponds to a lower Poisson's ratio, indicating less lateral expansion under compression. Understanding their key differences and interdependence is crucial for predicting material behavior under various mechanical loads in fields like materials science and structural engineering.

Poisson's ratio Infographic

libterm.com

libterm.com