Slip form is a continuous concrete pouring technique used to create seamless vertical structures like walls, silos, and towers efficiently. The method enhances structural integrity and speeds up construction by utilizing a moving formwork system that rises with the poured concrete. Explore the rest of the article to understand how slip form works and its applications in modern construction.

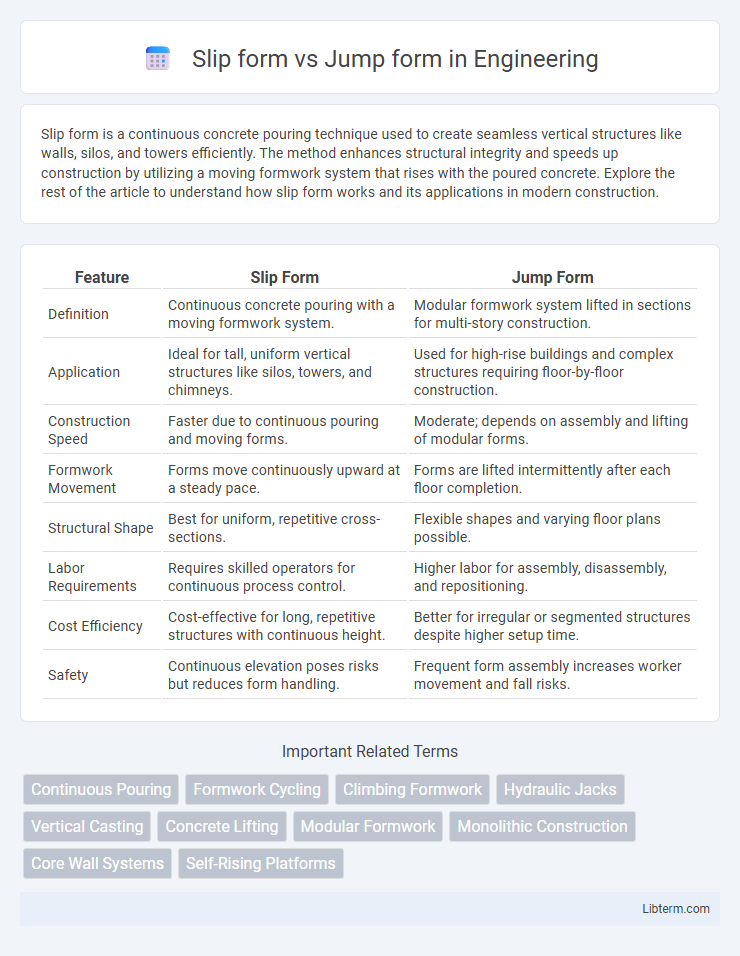

Table of Comparison

| Feature | Slip Form | Jump Form |

|---|---|---|

| Definition | Continuous concrete pouring with a moving formwork system. | Modular formwork system lifted in sections for multi-story construction. |

| Application | Ideal for tall, uniform vertical structures like silos, towers, and chimneys. | Used for high-rise buildings and complex structures requiring floor-by-floor construction. |

| Construction Speed | Faster due to continuous pouring and moving forms. | Moderate; depends on assembly and lifting of modular forms. |

| Formwork Movement | Forms move continuously upward at a steady pace. | Forms are lifted intermittently after each floor completion. |

| Structural Shape | Best for uniform, repetitive cross-sections. | Flexible shapes and varying floor plans possible. |

| Labor Requirements | Requires skilled operators for continuous process control. | Higher labor for assembly, disassembly, and repositioning. |

| Cost Efficiency | Cost-effective for long, repetitive structures with continuous height. | Better for irregular or segmented structures despite higher setup time. |

| Safety | Continuous elevation poses risks but reduces form handling. | Frequent form assembly increases worker movement and fall risks. |

Introduction to Slip Form and Jump Form

Slip form is a continuous pouring technique used in constructing vertical concrete structures such as silos, towers, and elevator shafts, allowing for uninterrupted upward movement of the formwork. Jump form involves modular, reusable climbing formwork with distinct stages, enabling efficient building of high-rise structures by sequentially moving the formwork to the next level after concrete sets. Both methods enhance construction speed and structural integrity, with slip form ideal for seamless, tall structures and jump form suited for segmented, multistory projects.

Key Differences Between Slip Form and Jump Form

Slip form involves continuous, vertical concrete pouring using a moving form system ideal for tall structures like silos and towers, enabling faster construction with fewer joints. Jump form utilizes climbing formwork that is dismantled and relocated floor-by-floor, suitable for building stairwells and elevator shafts with high precision in complex geometries. Key differences include slip form's continuous operation versus jump form's repetitive assembly process, and slip form's advantage in speed compared to jump form's flexibility in intricate structural shapes.

How Slip Form Works: Process and Techniques

Slip form works by continuously pouring concrete into a moving formwork system that slides upward at a controlled rate as the concrete sets and gains strength. Hydraulic jacks and synchronized winches enable the form to lift steadily, ensuring seamless vertical structures like towers and silos without construction joints. This technique requires precise timing, uniform concrete mix, and skilled operators to maintain structural integrity and surface quality throughout the slip-forming process.

Jump Form Construction: Process Overview

Jump form construction involves a climbing formwork system that moves upwards as the building rises, enabling continuous concrete pouring for high-rise structures. The process starts with assembling the jump form at the base, followed by concrete placement, curing, and then hydraulic lifting of the entire formwork to the next level. This method enhances construction speed, safety, and uniformity in tall building projects compared to traditional slip form techniques.

Advantages of Slip Form Construction

Slip form construction offers continuous, seamless concrete pouring, resulting in enhanced structural integrity and faster project completion times compared to jump form. This method allows for uninterrupted vertical progression, reducing labor costs and minimizing joint weaknesses in high-rise buildings and core structures. The efficiency and quality control inherent to slip form technology make it ideal for large-scale infrastructure projects requiring uniform strength and durability.

Benefits of Using Jump Form Systems

Jump form systems offer significant benefits including enhanced safety through enclosed working platforms, which reduce fall hazards on high-rise construction sites. Their modular design accelerates construction timelines by enabling simultaneous work on multiple building sections without waiting for the formwork to climb. Improved structural precision and alignment result from the rigid framework, ensuring consistent quality in concrete placement and minimizing rework.

Applications of Slip Form in Modern Projects

Slip form is widely applied in the construction of tall structures such as silos, chimneys, and high-rise buildings due to its continuous concrete pouring technique that enhances structural uniformity and reduces construction time. This method is highly favored in projects requiring vertical elements with consistent cross-sections, including bridge piers and elevator shafts. Its efficiency and adaptability in harsh weather conditions make slip form ideal for large-scale infrastructure projects, enabling seamless and rapid vertical construction.

Typical Uses for Jump Form Construction

Jump form construction is typically used for high-rise buildings and structures where repetitive floor designs require rapid vertical progression. It excels in projects like office towers, hotels, and residential skyscrapers due to its efficiency in forming walls and core structures continuously. This method enhances safety and productivity by allowing the formwork to be raised incrementally without disassembling, reducing construction time and labor costs.

Slip Form vs Jump Form: Cost Comparison

Slip form construction typically incurs lower labor costs due to its continuous pouring process, accelerating project timelines and reducing on-site labor hours compared to jump form. Jump form systems generally require higher initial investment for formwork and crane usage, but offer advantages in vertical accuracy and flexibility for complex structures, impacting overall cost. Evaluating project scale and complexity is essential; slip form is often more cost-effective for tall, repetitive structures, whereas jump form suits variable designs despite potentially higher costs.

Choosing the Right Formwork System for Your Project

Slip form and jump form are both efficient formwork systems used in high-rise construction, but selecting the right one depends on project specifics like height, material, and cycle time. Slip form suits continuous concrete pouring, offering speed and seamless walls for structures such as silos and chimneys, while jump form provides modular panels ideal for repetitive floor slabs with precise alignment in building cores. Evaluating factors like project timeline, structural complexity, and labor skillset ensures optimal formwork choice to balance cost efficiency and construction quality.

Slip form Infographic

libterm.com

libterm.com