Model Predictive Control (MPC) is an advanced method used to regulate complex systems by predicting future behavior and optimizing control moves accordingly. This approach enhances efficiency and stability in industrial processes, robotics, and energy management by continuously adjusting actions based on real-time data. Explore the rest of the article to understand how MPC can improve your system's performance and adaptability.

Table of Comparison

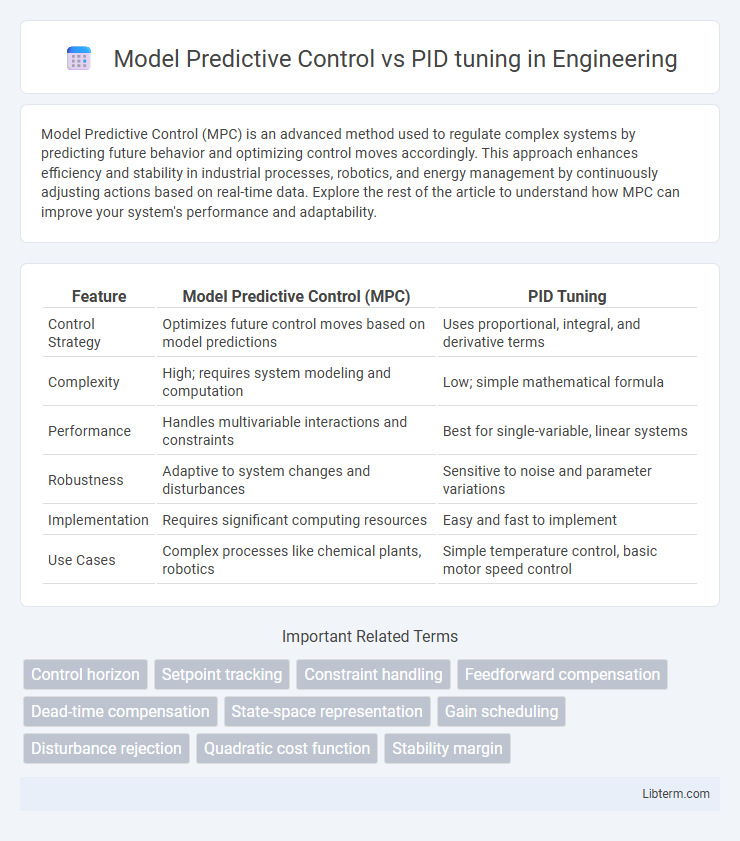

| Feature | Model Predictive Control (MPC) | PID Tuning |

|---|---|---|

| Control Strategy | Optimizes future control moves based on model predictions | Uses proportional, integral, and derivative terms |

| Complexity | High; requires system modeling and computation | Low; simple mathematical formula |

| Performance | Handles multivariable interactions and constraints | Best for single-variable, linear systems |

| Robustness | Adaptive to system changes and disturbances | Sensitive to noise and parameter variations |

| Implementation | Requires significant computing resources | Easy and fast to implement |

| Use Cases | Complex processes like chemical plants, robotics | Simple temperature control, basic motor speed control |

Introduction to Model Predictive Control and PID Tuning

Model Predictive Control (MPC) uses a dynamic model of the process to optimize control actions over a future time horizon, handling multivariable systems and constraints effectively. PID tuning adjusts proportional, integral, and derivative gains to achieve desired closed-loop performance, primarily for single-input single-output (SISO) systems. MPC offers advanced predictive capabilities and constraint management, while PID remains popular for its simplicity and ease of implementation in traditional control environments.

Core Principles of PID Control

PID control operates on three core principles: proportional action corrects current errors by applying a control effort proportional to the error magnitude; integral action eliminates steady-state errors by integrating past errors over time; derivative action predicts future errors by responding to the rate of error change. Effective PID tuning seeks to balance these actions to achieve stability, fast response, and minimal overshoot. Unlike Model Predictive Control, which uses a dynamic system model and optimization over a prediction horizon, PID control relies solely on real-time error feedback without explicit system modeling.

Fundamentals of Model Predictive Control

Model Predictive Control (MPC) optimizes control actions by solving a finite horizon optimization problem at each step, using a dynamic system model to predict future outputs. Unlike PID tuning, which adjusts fixed gains based on error feedback, MPC incorporates constraints and multivariable interactions directly into its control strategy. The fundamental strength of MPC lies in its ability to anticipate future disturbances and optimize control trajectories, ensuring improved performance for complex and constrained systems.

Key Differences Between MPC and PID Tuning

Model Predictive Control (MPC) utilizes a dynamic model of the process to predict future outputs and optimize control actions over a defined horizon, offering robustness in handling multivariable systems and constraints. PID tuning relies on adjusting proportional, integral, and derivative gains to correct errors based on current and past signals, making it simpler but less effective for complex or interacting processes. MPC provides proactive control by anticipating future disturbances, whereas PID tuning is reactive and primarily suitable for single-loop control scenarios.

Performance Comparison: Accuracy and Response

Model Predictive Control (MPC) outperforms PID tuning in accuracy by using a dynamic model of the process to anticipate future errors, leading to optimized control moves and reduced steady-state error. MPC's multivariable optimization enables faster response times and better handling of system constraints compared to PID controllers, which rely on fixed gain parameters and reactive adjustments. Performance comparison shows MPC delivers superior setpoint tracking and disturbance rejection, especially in complex, nonlinear, or multivariable systems, whereas PID remains effective in simpler, single-loop applications.

Handling Constraints in Control Systems

Model Predictive Control (MPC) excels in handling constraints within control systems by explicitly incorporating input and state limitations into the optimization problem solved at each control step. In contrast, PID tuning lacks inherent mechanisms for constraint management, often requiring external modifications or safety filters to prevent violations. MPC's predictive model enables anticipatory control actions that maintain system performance while respecting imposed boundaries, making it superior for constrained environments.

Implementation Complexity and Computational Requirements

Model Predictive Control (MPC) demands higher implementation complexity due to its reliance on dynamic system models, prediction horizons, and real-time optimization algorithms, requiring significant computational power and expertise in system identification and controller design. In contrast, PID tuning involves simpler implementation with straightforward parameter adjustments (proportional, integral, and derivative gains) and minimal computational requirements, making it suitable for systems with limited processing capabilities. MPC's computational requirements grow with system complexity and prediction horizon length, often necessitating advanced processors, whereas PID controllers can operate efficiently on basic microcontrollers.

Adaptability to Process Changes

Model Predictive Control (MPC) excels in adaptability to process changes by using a dynamic model to predict future behavior and optimize control actions over a moving horizon, allowing it to adjust proactively to disturbances and varying conditions. In contrast, PID tuning relies on fixed gain parameters, which often require manual retuning or adaptive schemes to handle changes effectively, limiting responsiveness to complex or nonlinear process variations. MPC's ability to incorporate constraints and multivariable interactions makes it more robust and flexible for systems experiencing frequent or unpredictable changes.

Common Applications and Use Cases

Model Predictive Control (MPC) is widely used in complex, multivariable industrial processes such as chemical reactors, oil refineries, and advanced manufacturing due to its ability to handle constraints and optimize future performance. PID tuning remains predominant in simpler or well-understood systems like HVAC, motor speed control, and basic process loops where straightforward feedback control suffices. Both control strategies are fundamental in automation, but MPC offers superior performance in applications requiring predictive adjustments and optimal control under constraints.

Future Trends in Advanced Process Control

Model Predictive Control (MPC) outperforms PID tuning by leveraging real-time optimization and multi-variable control, making it ideal for complex, dynamic processes. Future trends in advanced process control emphasize integrating MPC with machine learning algorithms and digital twins to enhance predictive accuracy and adaptive capabilities. The shift towards Industry 4.0 drives the adoption of cloud-based MPC solutions, enabling scalable, data-driven optimization and reduced operational costs.

Model Predictive Control Infographic

libterm.com

libterm.com