Plug flow reactors maintain a steady flow where reactants move through the reactor as a "plug," ensuring minimal back-mixing and a uniform residence time, ideal for continuous processes. Batch reactors operate by loading reactants into a vessel, mixing them thoroughly, and then processing for a set duration before emptying, which is well-suited for small-scale or variable production. Discover the key differences and applications of plug flow and batch reactors to optimize your chemical processing operations.

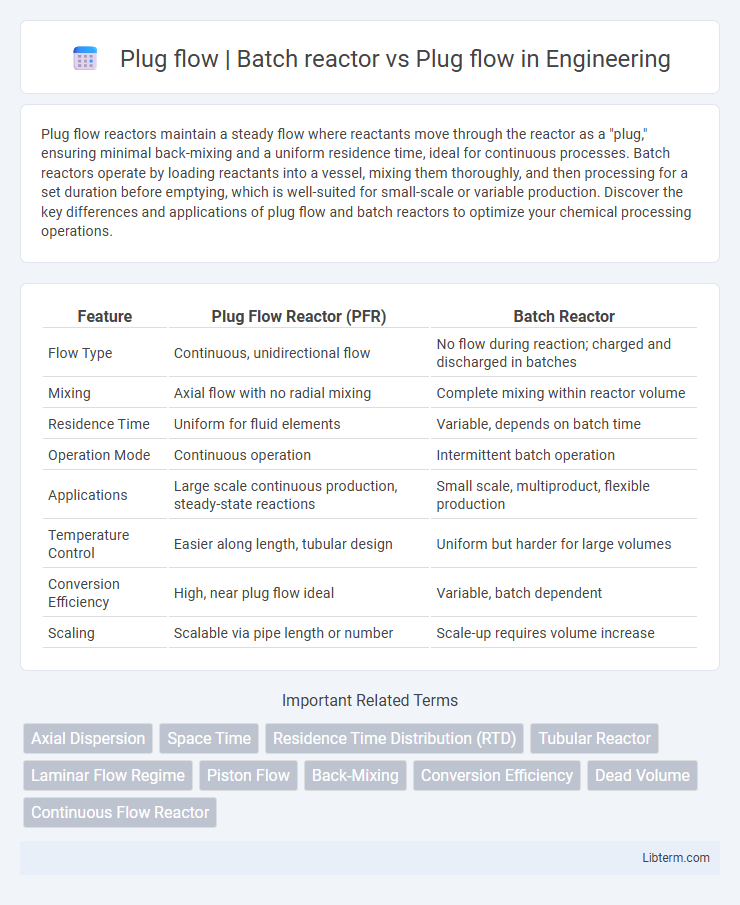

Table of Comparison

| Feature | Plug Flow Reactor (PFR) | Batch Reactor |

|---|---|---|

| Flow Type | Continuous, unidirectional flow | No flow during reaction; charged and discharged in batches |

| Mixing | Axial flow with no radial mixing | Complete mixing within reactor volume |

| Residence Time | Uniform for fluid elements | Variable, depends on batch time |

| Operation Mode | Continuous operation | Intermittent batch operation |

| Applications | Large scale continuous production, steady-state reactions | Small scale, multiproduct, flexible production |

| Temperature Control | Easier along length, tubular design | Uniform but harder for large volumes |

| Conversion Efficiency | High, near plug flow ideal | Variable, batch dependent |

| Scaling | Scalable via pipe length or number | Scale-up requires volume increase |

Introduction to Chemical Reactors

Plug flow reactors (PFRs) maintain a unidirectional flow where reactants move through the reactor as discrete fluid elements, allowing continuous operation with high conversion efficiency and minimal back-mixing. Batch reactors operate in a closed system where reactants are loaded, reacted over time, and products are removed, offering flexibility for small-scale or variable production but typically lower throughput. Understanding these reactor types is fundamental for optimizing reaction kinetics, residence time distribution, and process scale-up in chemical engineering applications.

What is a Plug Flow Reactor (PFR)?

A Plug Flow Reactor (PFR) is a type of chemical reactor where the fluid flows through a cylindrical pipe with a uniform velocity profile, maintaining a constant composition in radial direction while changing along the length. Unlike Batch Reactors, which treat reactants in a static volume allowing complete mixing, PFRs enable continuous operation with reactants moving as ideal "plugs" without back-mixing. This design optimizes reaction efficiency by maintaining high reactant concentration gradients, making PFRs ideal for fast, irreversible reactions in industrial applications.

What is a Batch Reactor?

A batch reactor is a closed system where reactants are loaded, reacted over time, and then products are removed, ideal for small-scale and flexible chemical processes. Unlike plug flow reactors (PFR), which maintain a continuous, steady movement of reactants through a tube, batch reactors operate without continuous inflow or outflow during the reaction phase. This design allows precise control over reaction time and conditions, making batch reactors suitable for complex or multi-step reactions requiring thorough mixing and temperature control.

Key Features of Plug Flow Reactors

Plug flow reactors (PFRs) are characterized by their continuous operation and directionally uniform flow, which minimizes back-mixing and ensures that reactants move through the reactor as discrete plugs. This setup promotes a high conversion efficiency for reactions with significant concentration gradients and allows precise control of reaction times and temperature profiles. Unlike batch reactors where the contents are mixed and reaction occurs uniformly over time, PFRs provide a steady-state environment ideal for large-scale chemical production with consistent product quality.

Key Features of Batch Reactors

Batch reactors operate with a fixed volume where reactants are loaded, reacted, and then removed, allowing precise control over reaction time and conditions. Unlike plug flow reactors, batch reactors provide uniform exposure of reactants to temperature and mixing, ideal for small-scale or multi-step syntheses. Their key features include flexibility in operation, suitability for complex reaction mixtures, and ability to handle variable reaction times efficiently.

Plug Flow vs Batch Reactor: Operational Differences

Plug flow reactors maintain a continuous, unidirectional flow where reactants enter and products exit simultaneously, ensuring uniform reaction time and concentration gradients along the reactor length. Batch reactors operate by charging reactants into a vessel, allowing the reaction to proceed over time without flow, resulting in variable concentration and temperature profiles throughout the reaction period. The key operational difference lies in plug flow's steady-state, spatially distributed conversion versus batch reactor's time-dependent, homogeneously mixed environment.

Efficiency Comparison: Plug Flow and Batch Reactors

Plug flow reactors (PFRs) offer higher efficiency in continuous processing by maintaining a steady concentration gradient and minimizing back-mixing, resulting in better conversion rates for first-order reactions compared to batch reactors. Batch reactors provide flexibility for small-scale production and complex reaction sequences but suffer from lower throughput and inconsistent reaction times. The superior efficiency of PFRs in handling large volumes and consistent reaction conditions makes them ideal for industrial-scale chemical manufacturing.

Advantages and Disadvantages of Plug Flow Reactors

Plug flow reactors (PFRs) offer high conversion efficiency for reactions with first-order kinetics due to their characteristic unidirectional flow and minimal back-mixing, leading to superior reactant utilization compared to batch reactors. PFRs provide consistent product quality and are suitable for continuous large-scale production, but they require precise control of flow rates and are less flexible for handling variable reaction times or multiple reaction steps than batch reactors. Limitations include complex design for handling highly viscous or multiphase mixtures and higher initial capital costs, though their scalability and efficiency benefits often outweigh these disadvantages in industrial applications.

Advantages and Disadvantages of Batch Reactors

Batch reactors offer flexibility in handling multiple reactions with varying operating conditions, making them ideal for small-scale production and synthesis of high-purity products. Advantages include ease of operation, simple design, and suitability for time-dependent reactions, while disadvantages involve limited scalability, uneven temperature and concentration distribution, and longer processing times compared to plug flow reactors. Plug flow reactors provide continuous operation with high conversion efficiency and consistent product quality, but lack the versatility inherent to batch systems.

Choosing Between Plug Flow and Batch Reactors: Factors to Consider

Choosing between plug flow and batch reactors depends on the reaction kinetics, production scale, and process control requirements. Plug flow reactors offer continuous operation with uniform residence time, ideal for large-scale processes and reactions needing precise temperature control. Batch reactors provide flexibility for small-scale, multi-product operations and are suitable for complex reaction sequences requiring variable reaction times.

Plug flow | Batch reactor Infographic

libterm.com

libterm.com