A tee joint is a fundamental welding connection where one pipe or metal piece intersects perpendicularly with another, forming a T shape. This type of joint is essential in piping systems and structural frameworks due to its ability to support load and fluid flow efficiently. Discover how mastering tee joints can enhance your welding projects by reading the full article.

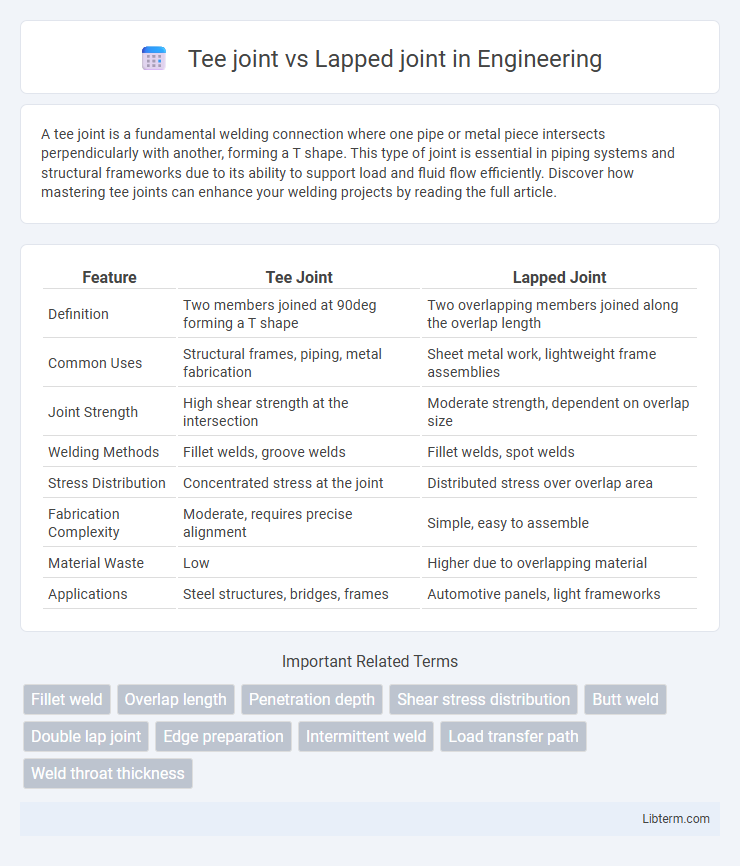

Table of Comparison

| Feature | Tee Joint | Lapped Joint |

|---|---|---|

| Definition | Two members joined at 90deg forming a T shape | Two overlapping members joined along the overlap length |

| Common Uses | Structural frames, piping, metal fabrication | Sheet metal work, lightweight frame assemblies |

| Joint Strength | High shear strength at the intersection | Moderate strength, dependent on overlap size |

| Welding Methods | Fillet welds, groove welds | Fillet welds, spot welds |

| Stress Distribution | Concentrated stress at the joint | Distributed stress over overlap area |

| Fabrication Complexity | Moderate, requires precise alignment | Simple, easy to assemble |

| Material Waste | Low | Higher due to overlapping material |

| Applications | Steel structures, bridges, frames | Automotive panels, light frameworks |

Introduction to Tee Joints and Lapped Joints

Tee joints involve joining two members at a 90-degree angle, forming a "T" shape commonly used in structural applications and piping systems. Lapped joints overlap two pieces of material side-by-side, providing increased surface area for welding or fastening, often found in sheet metal and woodworking. Both joints serve distinct mechanical and fabrication purposes, with tee joints offering perpendicular connections and lapped joints enhancing shear strength through surface contact.

Definition of Tee Joint

A Tee joint is a type of welded joint where two metal pieces are joined perpendicular to each other, forming a "T" shape, with one piece positioned at the middle of the other. This joint is commonly used in structural applications, piping, and fabrication where strength at the intersection is critical. Tee joints provide good strength and load distribution, especially when welds are applied along the edges of the perpendicular piece.

Definition of Lapped Joint

A lapped joint is a type of connection where two overlapping members are joined together by welding, bolting, or riveting, providing a larger surface area for load distribution. Unlike tee joints, where one member is perpendicular to another, lapped joints align members parallel, creating enhanced shear strength. This joint is commonly used in sheet metal work, structural applications, and automotive frames requiring strong, stable connections.

Structural Differences Between Tee and Lapped Joints

Tee joints connect two members at a 90-degree angle, forming a "T" shape where one member is perpendicular to the other, providing strong resistance to bending and shear forces. Lapped joints overlap two members in the same plane, distributing loads over a larger area but often exhibiting lower shear strength compared to tee joints. The primary structural difference lies in load transfer mechanisms and stress distribution: tee joints concentrate stresses at the intersection point, while lapped joints spread stresses across the overlap region.

Strength and Load-Bearing Comparison

Tee joints offer superior strength and load-bearing capacity due to their perpendicular configuration, which efficiently distributes stress across the welded area, making them ideal for structural applications. Lapped joints, while easier to fabricate, generally provide lower strength as the overlapping surfaces create stress concentration points that reduce load-bearing efficiency. The choice between tee and lapped joints significantly impacts the durability and stability of welded structures under dynamic and static loads.

Common Applications of Tee Joints

Tee joints are commonly used in structural frameworks, piping systems, and metal fabrication where two components meet at a perpendicular angle, providing strength and stability in load-bearing constructions. They are frequently found in bridge building, automotive chassis, and HVAC ductwork due to their ability to withstand stress and distribute forces effectively. Unlike lapped joints, which are suitable for overlapping materials, tee joints excel in applications requiring rigid right-angle connections.

Common Applications of Lapped Joints

Lapped joints are widely used in woodworking, metal fabrication, and automotive industries due to their simplicity and strength in overlapping materials. Common applications include frame construction, panel assembly, and sheet metal work where ease of alignment and load distribution across the joint are critical. These joints provide reliable resistance to shear forces, making them ideal for structural components and surface attachments.

Pros and Cons of Tee Joints

Tee joints provide a strong perpendicular connection ideal for frameworks and structural applications, offering excellent load-bearing capacity and ease of alignment. However, tee joints can be prone to stress concentration at the intersection, potentially leading to fatigue or cracking under cyclic loads without proper reinforcement. Compared to lapped joints, tee joints typically require more precise welding techniques and material preparation to ensure durability and prevent distortion.

Pros and Cons of Lapped Joints

Lapped joints offer strong mechanical stability and increased surface area for adhesive bonding, making them ideal for applications requiring reliable load distribution. However, they can lead to an increased thickness at the joint, potentially causing alignment issues and added weight in assembled structures. The overlapping design may also create stress concentration points, which can reduce fatigue resistance compared to other joint types like tee joints.

Choosing the Right Joint for Your Project

Tee joints provide strong perpendicular connections ideal for frameworks and structural applications, offering excellent load distribution along the intersecting parts. Lapped joints, characterized by overlapping surfaces, are preferred for their simplicity and increased bonding area in sheet metal and thin materials, enhancing resistance to shear forces. Choosing the right joint depends on material thickness, load requirements, and joint orientation; tee joints suit high-strength structural needs while lapped joints excel in lightweight, corrosion-resistant assemblies.

Tee joint Infographic

libterm.com

libterm.com