Fatigue resistance is a material's ability to withstand repeated stress cycles without failure, crucial for ensuring durability in mechanical components and structures. Understanding the factors influencing fatigue resistance, such as material composition, surface finish, and loading conditions, helps optimize performance and prevent unexpected breakdowns. Explore the rest of the article to learn how to enhance your designs with improved fatigue resistance techniques.

Table of Comparison

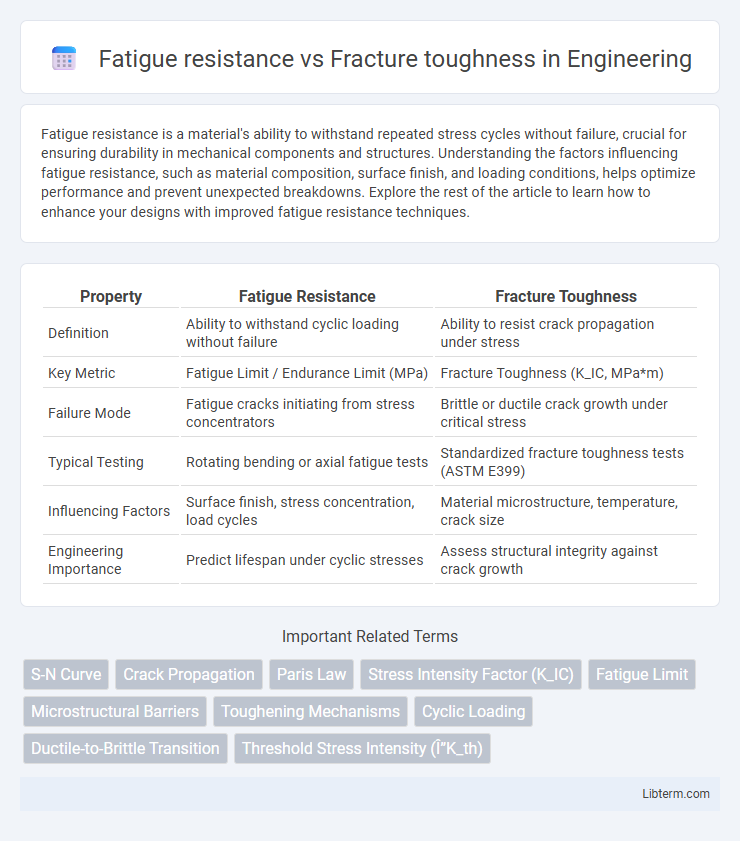

| Property | Fatigue Resistance | Fracture Toughness |

|---|---|---|

| Definition | Ability to withstand cyclic loading without failure | Ability to resist crack propagation under stress |

| Key Metric | Fatigue Limit / Endurance Limit (MPa) | Fracture Toughness (K_IC, MPa*m) |

| Failure Mode | Fatigue cracks initiating from stress concentrators | Brittle or ductile crack growth under critical stress |

| Typical Testing | Rotating bending or axial fatigue tests | Standardized fracture toughness tests (ASTM E399) |

| Influencing Factors | Surface finish, stress concentration, load cycles | Material microstructure, temperature, crack size |

| Engineering Importance | Predict lifespan under cyclic stresses | Assess structural integrity against crack growth |

Understanding Fatigue Resistance

Fatigue resistance measures a material's ability to withstand cyclic loading without failure, playing a critical role in applications subjected to repetitive stress. It depends on microstructural features such as grain size, phase distribution, and the presence of defects, which influence crack initiation and growth rates. Understanding fatigue resistance involves analyzing crack propagation behavior under fluctuating loads, which differs from fracture toughness that quantifies a material's capacity to resist crack propagation under a single, static load.

Defining Fracture Toughness

Fracture toughness measures a material's ability to resist crack propagation under stress, quantifying its capacity to withstand sudden fracture. This property is critical for evaluating structural components that experience high stress concentrations, ensuring they maintain integrity despite flaws. Fatigue resistance differs by describing a material's endurance under repeated cyclic loading without failure.

Key Differences: Fatigue Resistance vs Fracture Toughness

Fatigue resistance measures a material's ability to withstand repeated cyclic loading without crack initiation, whereas fracture toughness quantifies the capacity to resist crack propagation once a crack is present. Fatigue resistance is crucial for components subjected to fluctuating stresses, like aircraft wings, while fracture toughness is vital in assessing structural integrity under sudden or impact loads. These properties differ fundamentally: fatigue resistance involves endurance over time, and fracture toughness relates to the energy absorption and crack growth behavior under critical stress.

Material Microstructure and Its Impact

Material microstructure plays a crucial role in determining both fatigue resistance and fracture toughness by influencing crack initiation and propagation mechanisms. Fine-grained microstructures enhance fatigue resistance through improved crack closure and grain boundary strengthening, while tough microstructures with secondary phases or toughening mechanisms, such as transformation toughening or crack deflection, significantly improve fracture toughness. Optimizing grain size, phase distribution, and defect density within the microstructure directly controls the material's ability to resist cyclic loading and resist crack growth under stress.

Testing Methods for Fatigue and Fracture

Fatigue resistance testing commonly employs cyclic loading methods such as rotating bending, axial, or torsional fatigue tests to evaluate a material's ability to withstand repeated stress cycles before failure, characterized by S-N curves or stress-life data. Fracture toughness testing primarily uses standardized techniques like the compact tension (CT) and single-edge notched bend (SENB) tests to measure a material's resistance to crack propagation, quantified by parameters such as K_IC or J_IC values. Both testing methods are critical for understanding material performance under different loading conditions, with fatigue tests focusing on crack initiation and propagation over time, while fracture toughness tests assess the critical stress intensity factor at crack growth onset.

Real-World Applications and Performance

Fatigue resistance is crucial in components subjected to cyclic stresses, such as aircraft wings and automotive suspension systems, where materials must endure repeated loading without crack initiation. Fracture toughness defines a material's ability to resist crack propagation, vital in pressure vessels and structural bridges to prevent catastrophic failure once a crack forms. Balancing fatigue resistance and fracture toughness ensures longevity and safety in real-world applications, optimizing performance under complex, variable loading conditions.

Factors Influencing Fatigue Life

Fatigue resistance is predominantly influenced by factors such as material microstructure, surface finish, and the presence of stress concentrators like notches or cracks, which significantly affect crack initiation and propagation rates. Fracture toughness determines a material's ability to resist crack growth once a crack has formed, but fatigue life mainly depends on cyclic stress amplitude, environmental conditions, and loading frequency. Understanding the interplay between grain size, residual stresses, and corrosion effects is crucial for optimizing fatigue performance in engineering materials.

Enhancing Fracture Toughness: Techniques

Enhancing fracture toughness involves techniques such as alloying with elements like nickel or chromium to improve microstructural stability and crack tip blunting, as well as thermomechanical processing that refines grain size and induces beneficial residual stresses. Advanced surface treatments including laser peening and shot peening create compressive surface stresses that impede crack initiation and propagation, thereby increasing resistance to fracture. Incorporation of second-phase particles or ductile reinforcements within the matrix enhances energy absorption during crack growth, significantly improving overall fracture toughness.

Trade-offs in Material Selection

Fatigue resistance and fracture toughness often present trade-offs in material selection, as materials with high fatigue resistance typically exhibit lower fracture toughness and vice versa. Selecting alloys with enhanced fatigue resistance, such as titanium or aluminum alloys, can lead to reduced crack propagation rates but may compromise the ability to withstand sudden, high-stress impacts. Engineers must balance these properties based on application demands, considering factors like cyclic loading conditions and potential fracture risks to optimize performance and safety.

Recent Advances in Material Engineering

Recent advances in material engineering have significantly enhanced fatigue resistance and fracture toughness through the development of novel composite materials and nano-engineered alloys. Techniques such as additive manufacturing and controlled microstructure manipulation improve crack deflection and energy dissipation, thereby extending the lifespan of critical components in aerospace and automotive industries. Integration of machine learning algorithms for real-time monitoring and predictive maintenance further optimizes material performance against cyclic loading and fracture propagation.

Fatigue resistance Infographic

libterm.com

libterm.com