Fatigue often results from prolonged physical or mental exertion, leading to weakened energy levels and reduced productivity. Chronic fatigue may indicate underlying health issues that require professional attention for effective management. Discover more about the causes, symptoms, and remedies to regain your vitality by reading the full article.

Table of Comparison

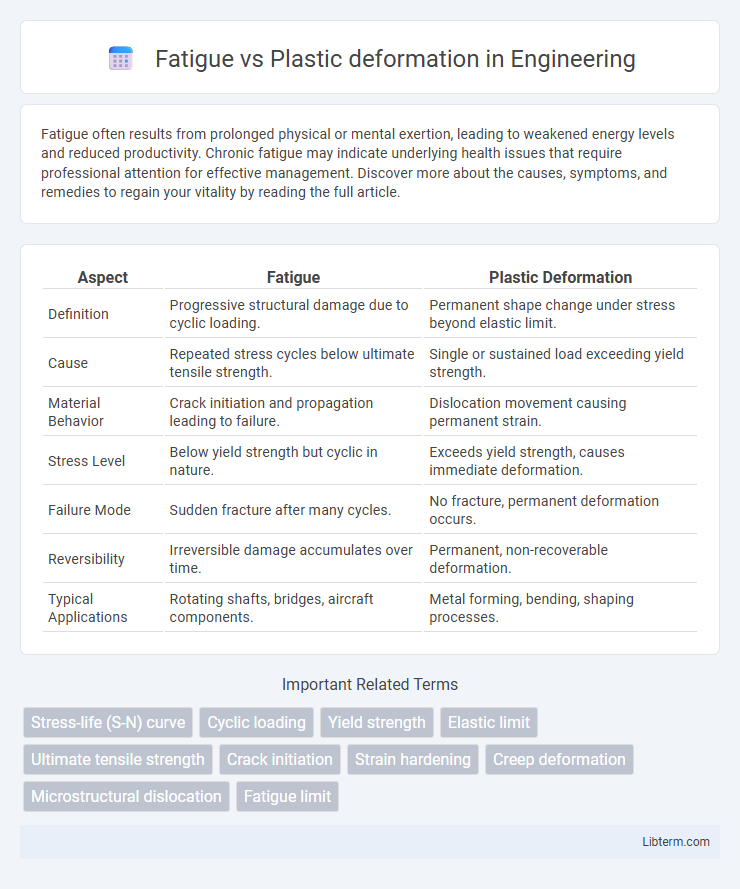

| Aspect | Fatigue | Plastic Deformation |

|---|---|---|

| Definition | Progressive structural damage due to cyclic loading. | Permanent shape change under stress beyond elastic limit. |

| Cause | Repeated stress cycles below ultimate tensile strength. | Single or sustained load exceeding yield strength. |

| Material Behavior | Crack initiation and propagation leading to failure. | Dislocation movement causing permanent strain. |

| Stress Level | Below yield strength but cyclic in nature. | Exceeds yield strength, causes immediate deformation. |

| Failure Mode | Sudden fracture after many cycles. | No fracture, permanent deformation occurs. |

| Reversibility | Irreversible damage accumulates over time. | Permanent, non-recoverable deformation. |

| Typical Applications | Rotating shafts, bridges, aircraft components. | Metal forming, bending, shaping processes. |

Introduction to Fatigue and Plastic Deformation

Fatigue refers to the progressive and localized structural damage that occurs when a material is subjected to cyclic loading, leading to the initiation and growth of cracks below its ultimate tensile strength. Plastic deformation involves the permanent, irreversible change in shape or size of a material under applied stress beyond its elastic limit, characterized by dislocation movement within the crystal lattice. Understanding the differences between fatigue and plastic deformation is crucial for predicting material failure, as fatigue relates to crack propagation under repeated stress, while plastic deformation involves sustained strain causing yield and shape change.

Defining Fatigue in Materials Science

Fatigue in materials science refers to the progressive and localized structural damage that occurs when a material is subjected to cyclic loading, leading to the initiation and growth of cracks over time. This phenomenon differs from plastic deformation, which involves a permanent change in shape resulting from a single or sustained load exceeding the material's yield strength. Understanding fatigue behavior is critical for predicting the lifespan of components exposed to repetitive stress, particularly in metals and alloys commonly used in engineering applications.

Understanding Plastic Deformation

Plastic deformation occurs when a material undergoes irreversible changes in shape due to applied stress exceeding its yield strength, resulting in dislocation movement within the crystal structure. Unlike fatigue, which involves progressive damage from cyclic loading, plastic deformation involves permanent strain from a single or sustained load. Understanding plastic deformation is critical for predicting a material's behavior under overload conditions and designing components to avoid failure through strain hardening or controlled ductility.

Key Differences Between Fatigue and Plastic Deformation

Fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading, whereas plastic deformation is the permanent change in shape resulting from a single or sustained application of stress beyond the elastic limit. Fatigue failure typically initiates from microscopic cracks that grow over time, while plastic deformation involves dislocation movement and slip within the material's crystal structure. The key difference lies in fatigue being time-dependent and repetitive stress-driven, while plastic deformation is an instantaneous response to stress exceeding yield strength.

Causes of Fatigue Failure

Fatigue failure occurs due to repeated cyclic loading that induces microscopic cracks in materials, eventually leading to fracture under stress levels lower than the material's ultimate tensile strength. Unlike plastic deformation, which involves permanent shape change from exceeding yield stress in a single event, fatigue damage accumulates progressively from stress variations below the yield limit. Key causes include stress concentration points, surface flaws, corrosion, and material defects that accelerate crack initiation and propagation during persistent loading cycles.

Mechanisms of Plastic Deformation

Plastic deformation occurs through the movement and multiplication of dislocations within a material's crystal lattice, enabling irreversible shape changes under applied stress. Mechanisms such as slip, twinning, and grain boundary sliding facilitate this deformation by altering atomic arrangements without fracturing the material. In contrast to fatigue, which involves cyclic loading and crack initiation, plastic deformation primarily concerns permanent strain accumulation resulting from dislocation dynamics and microstructural evolution.

Effects of Stress and Strain on Materials

Fatigue occurs when cyclic stress and strain cause progressive material damage leading to crack initiation and growth, often below the material's yield strength, whereas plastic deformation results from stress surpassing the yield strength causing permanent shape change. Under repeated loading, fatigue induces microstructural changes such as dislocation movement and initiation of microcracks, while plastic deformation involves significant dislocation motion and strain hardening. Stress amplitude, mean stress, and strain range critically influence fatigue life, while the magnitude and rate of applied stress determine the extent of plastic strain and ultimate material failure.

Real-World Examples of Fatigue vs Plastic Deformation

Fatigue often occurs in aircraft wings and bridges, where repeated stress cycles cause microscopic cracks that propagate over time, eventually leading to failure without significant permanent deformation. Plastic deformation is commonly observed in metal components of automotive crash zones, where materials undergo permanent shape changes to absorb impact energy. Understanding these real-world examples highlights how fatigue involves progressive damage under cyclic loading, whereas plastic deformation results from stress exceeding yield strength, causing irreversible material changes.

Prevention and Mitigation Strategies

Fatigue prevention focuses on reducing cyclic stresses through design improvements like stress concentrator removal, surface treatments such as shot peening, and material selection with high fatigue strength. Plastic deformation mitigation involves controlling applied loads to remain within the elastic limit and using heat treatments to enhance material ductility and hardness. Employing appropriate inspection techniques, including non-destructive testing, enables early detection and management of fatigue cracks before plastic deformation occurs.

Summary and Conclusion

Fatigue involves the progressive and localized structural damage occurring under cyclic loading, leading to failure at stress levels below the material's ultimate tensile strength. Plastic deformation is the permanent, non-reversible strain resulting from stresses exceeding the yield strength, altering the material's microstructure. Understanding the distinctions aids in predicting component lifespan and selecting appropriate materials for fatigue resistance and structural integrity.

Fatigue Infographic

libterm.com

libterm.com