An autotransformer is an electrical transformer with a single winding that acts as both the primary and secondary, offering voltage transformation with higher efficiency and reduced size compared to conventional transformers. It is commonly used in applications requiring voltage regulation, such as in power distribution and motor starting, providing cost-effective solutions for your electrical needs. Explore the rest of the article to understand how autotransformers function and their practical advantages.

Table of Comparison

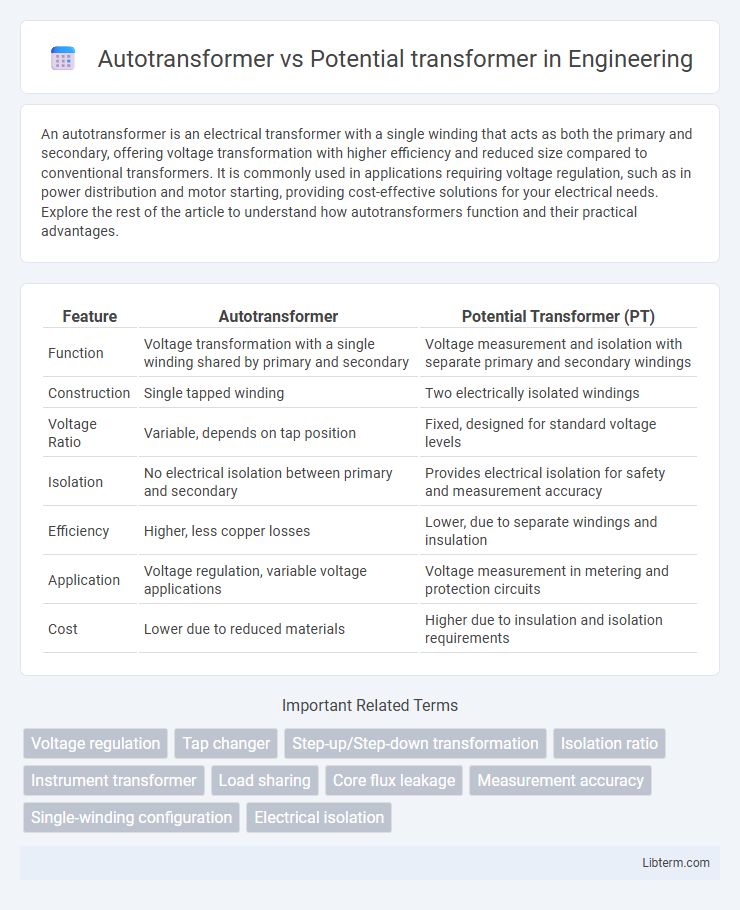

| Feature | Autotransformer | Potential Transformer (PT) |

|---|---|---|

| Function | Voltage transformation with a single winding shared by primary and secondary | Voltage measurement and isolation with separate primary and secondary windings |

| Construction | Single tapped winding | Two electrically isolated windings |

| Voltage Ratio | Variable, depends on tap position | Fixed, designed for standard voltage levels |

| Isolation | No electrical isolation between primary and secondary | Provides electrical isolation for safety and measurement accuracy |

| Efficiency | Higher, less copper losses | Lower, due to separate windings and insulation |

| Application | Voltage regulation, variable voltage applications | Voltage measurement in metering and protection circuits |

| Cost | Lower due to reduced materials | Higher due to insulation and isolation requirements |

Introduction to Autotransformers and Potential Transformers

Autotransformers are electrical transformers with a single winding that acts as both the primary and secondary winding, allowing voltage adjustment with higher efficiency and reduced size compared to traditional transformers. Potential transformers (PTs) are specialized transformers designed to step down high voltages to lower, standardized levels for safe measurement and protection in power systems. Unlike autotransformers, potential transformers provide electrical isolation between high voltage and measuring instruments, ensuring accuracy and safety in voltage monitoring.

Core Working Principles of Autotransformers

Autotransformers operate on the principle of electromagnetic induction using a single winding that acts as both the primary and secondary, sharing part of the winding to transfer energy efficiently. The variable tap on the winding allows for voltage adjustment by changing the turns ratio, which results in a compact design with reduced materials compared to two-winding transformers. These transformers provide voltage transformation with a direct electrical connection between input and output, making them suitable for applications requiring voltage regulation and stepping up or down voltages within a limited range.

Core Working Principles of Potential Transformers

Potential transformers operate by using electromagnetic induction to step down high voltages to a lower, standardized voltage suitable for measurement and protection systems, maintaining accuracy and safety in electrical grids. Their core working principle involves two magnetically coupled windings where the primary winding connects to the high voltage line, and the secondary winding delivers a proportional, scaled voltage output. Unlike autotransformers, potential transformers provide electrical isolation between primary and secondary circuits, essential for preventing high voltage from reaching measurement instruments.

Key Differences Between Autotransformer and Potential Transformer

Autotransformers feature a single winding acting as both primary and secondary, enabling voltage transformation with higher efficiency and lower cost, whereas potential transformers have separate primary and secondary windings for electrical isolation. Autotransformers are typically used for voltage regulation and step-up or step-down applications, while potential transformers provide accurate voltage measurement and isolation in metering and protection circuits. The key difference lies in isolation and application: potential transformers ensure galvanic isolation for safety and precision, whereas autotransformers afford compact design and efficiency but lack isolation.

Construction and Design Basics

An autotransformer consists of a single winding with taps at different points to provide voltage transformation, allowing for compact design and reduced material use. A potential transformer features two separate windings, primary and secondary, electrically isolated to ensure accurate voltage measurement and safety. The autotransformer's continuous winding design contrasts with the potential transformer's distinct coil arrangement optimized for precise voltage reduction and isolation.

Voltage Regulation and Transformation Efficiency

Autotransformers exhibit superior voltage regulation due to their shared winding design, resulting in minimal voltage drops under load compared to potential transformers, which rely on separate primary and secondary windings. The transformation efficiency of autotransformers is significantly higher, often exceeding 98%, as they transfer power both electrically and magnetically, whereas potential transformers typically have lower efficiency due to energy losses in magnetic coupling and insulation. These characteristics make autotransformers more suitable for applications requiring stable voltage output and energy-efficient voltage transformation.

Typical Applications of Autotransformers

Autotransformers are commonly used in voltage regulation and adjustment applications such as motor starting, voltage step-up or step-down in power distribution, and testing laboratories due to their compact size and efficiency. They are ideal for boosting voltage in transmission lines, supplying variable voltage to electrical equipment, and providing isolation in low-voltage scenarios. Unlike potential transformers primarily used for measurement and protection, autotransformers excel in power delivery where continuous voltage variation and load sharing are critical.

Typical Applications of Potential Transformers

Potential transformers are commonly used in power system metering and protection to step down high voltage levels to standardized low voltages for accurate measurement and monitoring. They are essential in electrical substations, switchgear, and control panels to provide voltage inputs to instrumentation and relays. In contrast, autotransformers are primarily employed for voltage regulation and low-power applications rather than precise voltage measurement.

Advantages and Limitations Comparison

Autotransformers offer higher efficiency and reduced size compared to potential transformers due to their single winding design, making them cost-effective for voltage regulation in power systems. However, autotransformers do not provide electrical isolation between primary and secondary circuits, limiting their use in applications requiring safety isolation, which potential transformers ensure by having separate primary and secondary windings. Potential transformers provide accurate voltage measurement with galvanic isolation, enhancing safety but often at the expense of increased size, cost, and reduced efficiency compared to autotransformers.

Safety Considerations and Best Practices

Autotransformers have a shared winding for both primary and secondary sides, which poses higher electric shock risks compared to potential transformers that have galvanic isolation, enhancing safety. Best practices for autotransformers include ensuring proper insulation and grounding, while potential transformers require regular insulation testing and secure enclosure to prevent accidental contact. Safety considerations prioritize using potential transformers in metering and protective relaying to minimize hazardous exposure and ensure accurate voltage measurement.

Autotransformer Infographic

libterm.com

libterm.com