Pearlitic microstructure in steel consists of alternating layers of ferrite and cementite, providing a unique combination of strength and ductility. This lamellar structure forms during the slow cooling of austenite, directly influencing the hardenability and wear resistance of the alloy. Explore the rest of the article to understand how pearlitic properties impact your material selection and performance outcomes.

Table of Comparison

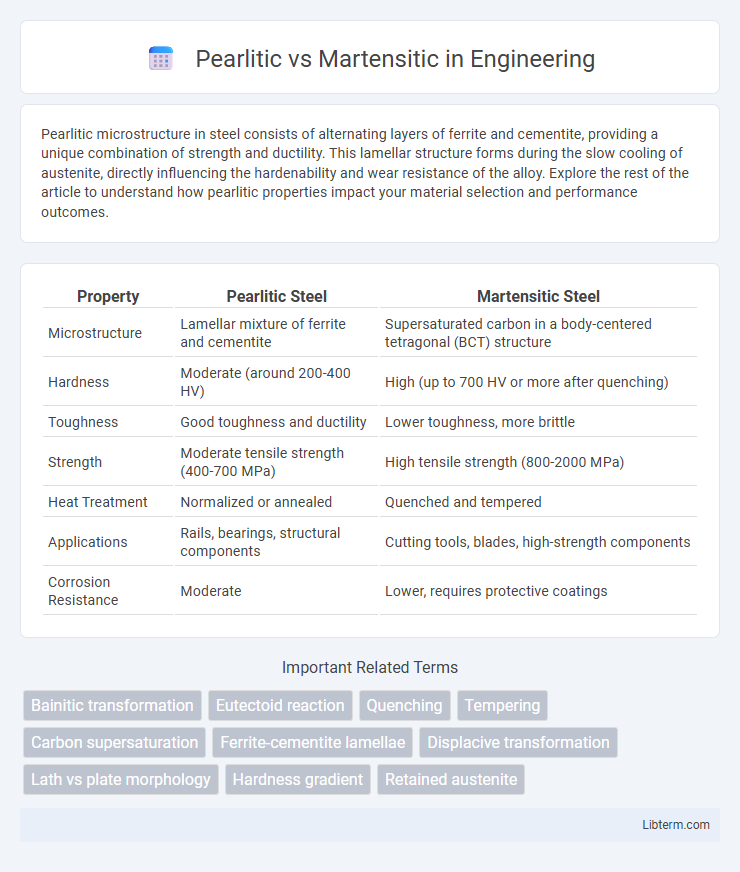

| Property | Pearlitic Steel | Martensitic Steel |

|---|---|---|

| Microstructure | Lamellar mixture of ferrite and cementite | Supersaturated carbon in a body-centered tetragonal (BCT) structure |

| Hardness | Moderate (around 200-400 HV) | High (up to 700 HV or more after quenching) |

| Toughness | Good toughness and ductility | Lower toughness, more brittle |

| Strength | Moderate tensile strength (400-700 MPa) | High tensile strength (800-2000 MPa) |

| Heat Treatment | Normalized or annealed | Quenched and tempered |

| Applications | Rails, bearings, structural components | Cutting tools, blades, high-strength components |

| Corrosion Resistance | Moderate | Lower, requires protective coatings |

Introduction to Steel Microstructures

Pearlitic and martensitic microstructures represent fundamental phases in steel, each defined by distinct atomic arrangements and mechanical properties. Pearlitic steel features alternating layers of ferrite and cementite, providing a balance of strength and ductility crucial for structural applications. Martensitic steel forms through rapid quenching, producing a supersaturated carbon structure that offers exceptional hardness and wear resistance for tool and blade manufacturing.

Overview of Pearlitic and Martensitic Structures

Pearlitic structures consist of alternating layers of ferrite and cementite, providing a balance of strength and ductility commonly found in medium to high carbon steels. Martensitic structures form through rapid quenching, creating a supersaturated solid solution of carbon in body-centered tetragonal iron, which results in high hardness and strength but reduced ductility. The unique microstructures of pearlite and martensite significantly influence the mechanical properties and applications of steels.

Formation Mechanisms of Pearlite and Martensite

Pearlite forms through a diffusion-controlled transformation where austenite decomposes into alternating layers of ferrite and cementite during slow cooling, enabling carbon atoms to migrate and segregate accordingly. Martensite forms via a diffusionless, shear-dominated transformation in which rapid quenching traps carbon atoms in a supersaturated body-centered tetragonal structure, causing a hard and brittle phase. The fundamental difference lies in pearlite's reliance on carbon diffusion and equilibrium phase separation versus martensite's rapid, non-diffusional lattice distortion.

Microstructural Characteristics

Pearlitic microstructure consists of alternating layers of ferrite and cementite, providing a balance of strength and ductility due to its lamellar arrangement. Martensitic microstructure forms through rapid quenching, resulting in a supersaturated, distorted body-centered tetragonal structure that is hard and brittle. The transformation from austenite to martensite lacks diffusion, creating a needle-like, acicular morphology distinct from the layered pearlite.

Mechanical Properties Comparison

Pearlitic steel exhibits high strength combined with good ductility due to its layered microstructure of ferrite and cementite, making it suitable for wear-resistant applications. Martensitic steel offers superior hardness and tensile strength derived from its body-centered tetragonal structure formed through rapid quenching, but it typically has lower ductility and increased brittleness. The trade-off between these mechanical properties positions pearlitic steel for toughness-focused uses, while martensitic steel excels in high-strength, high-hardness components like cutting tools and automotive parts.

Heat Treatment and Transformation Processes

Pearlitic steel undergoes a slow cooling heat treatment that allows the formation of alternating layers of ferrite and cementite, resulting in improved toughness and moderate strength. Martensitic steel forms through rapid quenching from the austenite phase, producing a hard and brittle microstructure due to trapped carbon atoms in a distorted body-centered tetragonal lattice. Controlling the heat treatment parameters such as cooling rate and tempering temperature is critical to tailor the mechanical properties associated with pearlitic and martensitic transformations.

Applications in Industry

Pearlitic steels are widely used in automotive components, rail tracks, and machinery parts due to their excellent wear resistance and moderate strength, offering durability under cyclic loads. Martensitic steels find extensive applications in cutting tools, blades, and high-strength structural components because of their superior hardness and tensile strength achieved through heat treatment. Industries such as aerospace and defense favor martensitic alloys for their impact resistance and toughness in critical performance environments.

Advantages and Disadvantages

Pearlitic steel offers excellent wear resistance and machinability due to its layered microstructure, making it ideal for applications requiring toughness and moderate strength. Martensitic steel provides superior hardness and tensile strength from its quenched and tempered microstructure, but it tends to be more brittle and less ductile. Pearlitic steels are better suited for machining and shock absorption, whereas martensitic steels excel in high-strength and wear-resistant components but require careful heat treatment to avoid brittleness.

Impact on Wear and Corrosion Resistance

Pearlitic steel offers moderate wear resistance due to its lamellar structure of alternating ferrite and cementite, which provides balanced strength and toughness. Martensitic steel exhibits superior wear resistance because of its hardened, tetragonal crystal structure formed through rapid quenching, enhancing hardness and reducing material degradation under abrasive conditions. Corrosion resistance in pearlitic steel is generally lower compared to martensitic steel, as the latter's higher carbon content and heat treatment improve passivation and resistance to oxidative environments.

Selection Criteria for Engineering Uses

Pearlitic steels offer high strength and good wear resistance, making them ideal for applications like rails and cutting tools where toughness and durability are essential. Martensitic steels provide superior hardness and tensile strength due to their fine, needle-like microstructure, suitable for high-strength components such as blades and structural parts requiring excellent fatigue resistance. Selection criteria focus on balancing hardness, toughness, and machinability, with pearlitic preferred for applications needing moderate strength and ductility, and martensitic chosen for maximum hardness and strength under demanding mechanical loads.

Pearlitic Infographic

libterm.com

libterm.com