Fatigue strength refers to the maximum stress a material can endure for a specified number of cycles without failure, making it essential in predicting a component's durability under repeated loading. Understanding fatigue strength helps prevent unexpected breakdowns in mechanical parts and structural elements, thereby ensuring safety and reliability. Explore the article to learn how fatigue strength impacts your designs and material selection.

Table of Comparison

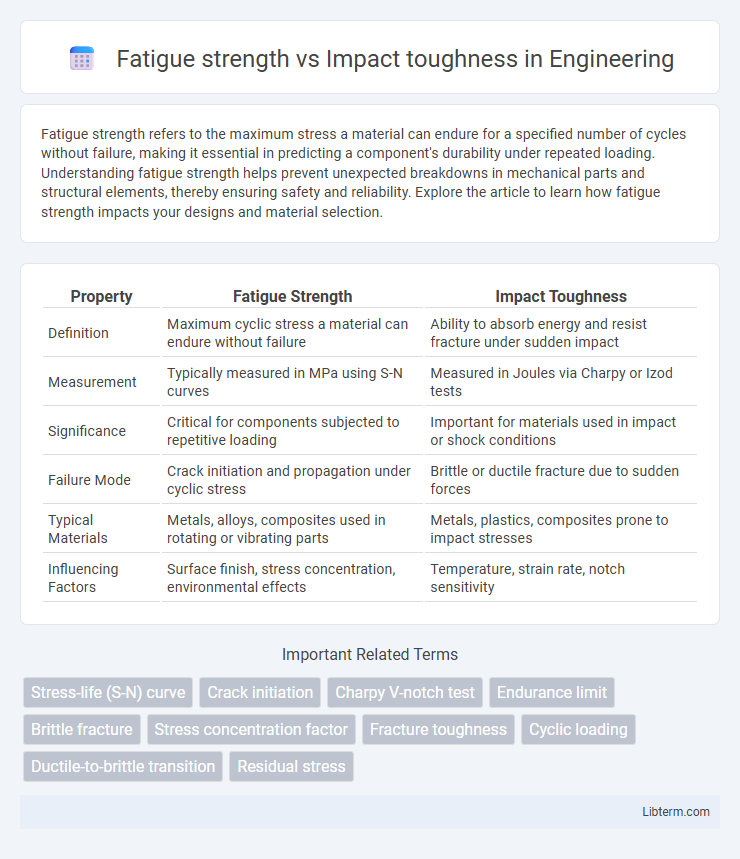

| Property | Fatigue Strength | Impact Toughness |

|---|---|---|

| Definition | Maximum cyclic stress a material can endure without failure | Ability to absorb energy and resist fracture under sudden impact |

| Measurement | Typically measured in MPa using S-N curves | Measured in Joules via Charpy or Izod tests |

| Significance | Critical for components subjected to repetitive loading | Important for materials used in impact or shock conditions |

| Failure Mode | Crack initiation and propagation under cyclic stress | Brittle or ductile fracture due to sudden forces |

| Typical Materials | Metals, alloys, composites used in rotating or vibrating parts | Metals, plastics, composites prone to impact stresses |

| Influencing Factors | Surface finish, stress concentration, environmental effects | Temperature, strain rate, notch sensitivity |

Understanding Fatigue Strength

Fatigue strength refers to a material's ability to withstand cyclic loading without failure, crucial for applications subjected to repetitive stress such as bridges, aircraft, and automotive components. It is typically evaluated by the number of cycles a material can endure before crack initiation occurs under a specified stress amplitude, often measured using S-N curves (stress versus number of cycles). Understanding fatigue strength helps engineers predict service life, optimize material selection, and design components that resist crack propagation under fluctuating loads.

Defining Impact Toughness

Impact toughness measures a material's ability to absorb energy and plastically deform without fracturing under sudden, high-velocity forces, usually tested by Charpy or Izod impact tests. Fatigue strength defines the maximum stress a material can withstand for a given number of cycles without failure, emphasizing resistance to repeated loading rather than sudden impacts. Impact toughness is critical for applications requiring resistance to shock loading, while fatigue strength is essential for durability under cyclic stresses.

Key Differences: Fatigue Strength vs Impact Toughness

Fatigue strength measures a material's ability to withstand cyclic loading without failure over time, while impact toughness evaluates the energy a material can absorb during a sudden impact or shock. Fatigue strength is critical in components subjected to fluctuating stresses, such as rotating shafts, whereas impact toughness is vital for applications requiring resistance to brittle fracture under rapid loading, like structural beams. The key difference lies in fatigue strength addressing durability under repeated stress, while impact toughness focuses on material behavior under instantaneous force.

Factors Influencing Fatigue Strength

Fatigue strength is primarily influenced by factors such as material microstructure, surface finish, and stress concentration, which govern a material's ability to withstand cyclic loading without failure. Impact toughness, on the other hand, measures a material's capacity to absorb energy during sudden impact and is affected by temperature, strain rate, and material ductility. Understanding the interplay between microstructural properties and environmental conditions is essential for optimizing fatigue performance in engineering applications.

Factors Affecting Impact Toughness

Impact toughness depends significantly on material composition, microstructure, temperature, and loading rate, as these factors influence the material's ability to absorb energy during sudden impacts. Grain size refinement, alloying elements, and heat treatment can enhance toughness by promoting ductile fracture mechanisms. Low temperatures and high strain rates typically reduce impact toughness by encouraging brittle fracture modes.

Testing Methods for Fatigue Strength

Fatigue strength testing methods primarily involve cyclic stress application through rotating bending, axial fatigue, or flexural fatigue tests to determine the material's endurance limit under repeated loading. Specimens are subjected to controlled stress amplitudes until failure occurs or a predetermined number of cycles is reached, enabling the generation of S-N curves that illustrate fatigue life. This contrasts with impact toughness testing, which uses rapid energy absorption measurements like Charpy or Izod tests to evaluate a material's resistance to sudden fracture.

Standard Tests for Impact Toughness

Impact toughness is commonly measured by standard tests such as the Charpy V-Notch (CVN) and Izod tests, which determine a material's ability to absorb energy during sudden impact. In contrast, fatigue strength evaluates a material's endurance limit under cyclic loading conditions, typically assessed through fatigue testing procedures like rotating bending or axial fatigue tests. While fatigue strength focuses on resistance to fracture over repeated stress, impact toughness directly quantifies the material's resistance to crack propagation under high-strain-rate impacts per ASTM E23 standards.

Material Selection: Fatigue vs Impact Criteria

Fatigue strength measures a material's resistance to crack initiation and propagation under cyclic loading, critical for components subjected to repetitive stress such as gears and shafts. Impact toughness quantifies a material's ability to absorb energy during sudden, high-strain-rate events, essential for applications vulnerable to shock or impact like automotive bumpers and protective gear. Selecting materials based on fatigue criteria prioritizes endurance under fluctuating loads, whereas impact criteria emphasize energy absorption capacity to prevent brittle failure.

Applications Requiring High Fatigue Strength

Applications requiring high fatigue strength, such as aerospace components and automotive suspension systems, demand materials that can endure repeated cyclic loading without failure. Fatigue strength is critical for parts subjected to fluctuating stresses over time, ensuring longevity and reliability under operational conditions. Unlike impact toughness, which measures energy absorption during sudden impacts, fatigue strength specifically addresses resistance to crack initiation and propagation under repeated stress cycles.

Situations Demanding Superior Impact Toughness

Situations demanding superior impact toughness include structures subject to sudden, high-velocity impacts such as automotive crash components, aerospace parts exposed to bird strikes, and industrial machinery experiencing unexpected shocks. Impact toughness measures a material's ability to absorb energy and resist fracture under rapid loading, which is critical for preventing catastrophic failure in these scenarios. Unlike fatigue strength, which gauges resistance to cyclic loading over time, impact toughness ensures durability against instantaneous, high-energy impacts.

Fatigue strength Infographic

libterm.com

libterm.com