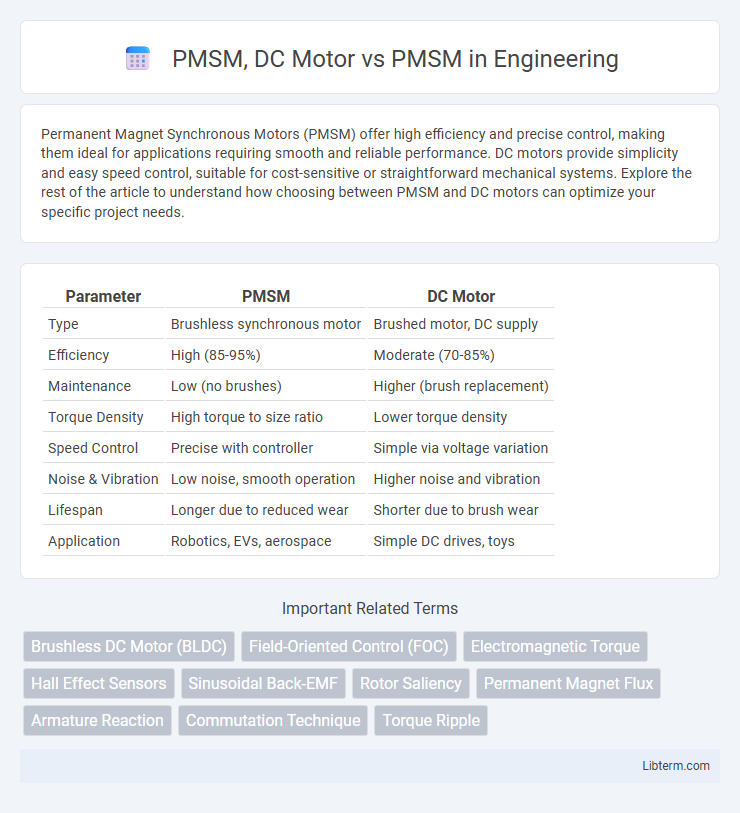

Permanent Magnet Synchronous Motors (PMSM) offer high efficiency and precise control, making them ideal for applications requiring smooth and reliable performance. DC motors provide simplicity and easy speed control, suitable for cost-sensitive or straightforward mechanical systems. Explore the rest of the article to understand how choosing between PMSM and DC motors can optimize your specific project needs.

Table of Comparison

| Parameter | PMSM | DC Motor |

|---|---|---|

| Type | Brushless synchronous motor | Brushed motor, DC supply |

| Efficiency | High (85-95%) | Moderate (70-85%) |

| Maintenance | Low (no brushes) | Higher (brush replacement) |

| Torque Density | High torque to size ratio | Lower torque density |

| Speed Control | Precise with controller | Simple via voltage variation |

| Noise & Vibration | Low noise, smooth operation | Higher noise and vibration |

| Lifespan | Longer due to reduced wear | Shorter due to brush wear |

| Application | Robotics, EVs, aerospace | Simple DC drives, toys |

Introduction to PMSM: Basics and Applications

Permanent Magnet Synchronous Motors (PMSMs) utilize permanent magnets embedded in the rotor to create a constant magnetic field, enabling efficient and precise control of rotational speed and torque. Compared to traditional DC motors, PMSMs offer higher power density, improved efficiency, and reduced maintenance due to the absence of brushes and commutators. Commonly employed in electric vehicles, industrial robotics, and aerospace applications, PMSMs provide reliable performance in environments demanding high dynamic response and energy efficiency.

Understanding DC Motors: Principles and Uses

DC motors operate on the principle of converting direct current electrical energy into mechanical energy through electromagnetic interactions between the stator and rotor. Commonly used in applications requiring variable speed control and high starting torque, DC motors are found in electric vehicles, industrial machines, and household appliances. Their simplicity, ease of control, and reliable performance make them a fundamental choice for many low- to medium-power motor applications compared to the more complex Permanent Magnet Synchronous Motors (PMSM).

Key Differences Between PMSM and DC Motors

PMSMs (Permanent Magnet Synchronous Motors) use permanent magnets in the rotor and rely on synchronous operation with the stator's rotating magnetic field, resulting in higher efficiency and better performance at varying speeds compared to traditional DC motors. DC motors operate using a commutator and brushes to switch current direction, which causes higher maintenance and lower efficiency due to mechanical wear and sparking. PMSMs offer improved torque density, quieter operation, and reduced electromagnetic interference, making them ideal for applications requiring precision and reliability.

Efficiency Comparison: PMSM vs DC Motor

Permanent Magnet Synchronous Motors (PMSMs) offer higher efficiency than traditional DC motors due to their reduced energy losses and improved power density. PMSMs feature better torque-to-inertia ratios and lower heat generation, resulting in enhanced performance in variable speed applications. Compared to DC motors, PMSMs demonstrate superior energy savings, especially in high-load or continuous operation scenarios.

Performance Characteristics of PMSM

Permanent Magnet Synchronous Motors (PMSMs) exhibit high efficiency and superior torque density compared to traditional DC motors, making them ideal for precision applications. PMSMs deliver consistent speed control and reduced electromagnetic losses due to their sinusoidal back EMF and rotor design with permanent magnets. These performance characteristics result in enhanced dynamic response and lower maintenance requirements, outperforming DC motors in energy efficiency and reliability.

Control Techniques: PMSM vs DC Motor

Field-oriented control (FOC) is the dominant technique for PMSM, offering precise torque and speed regulation by decoupling flux and torque control, which enhances efficiency and dynamic response. DC motors typically use simpler armature voltage control and PWM techniques but lack the sophisticated vector control methods available for PMSMs. Advanced control algorithms in PMSMs enable superior performance in precision and energy savings compared to traditional DC motor controls.

Maintenance and Reliability Factors

Permanent Magnet Synchronous Motors (PMSMs) require less maintenance compared to DC motors due to the absence of brushes and commutators, reducing wear and sparking issues. PMSMs offer higher reliability with longer service life and lower operational costs, stemming from their robust design and improved thermal management. In contrast, DC motors necessitate frequent inspections and replacements of brushes and commutators, increasing downtime and maintenance expenses.

Cost Considerations: PMSM Compared to DC Motor

Permanent Magnet Synchronous Motors (PMSMs) generally have higher initial costs than traditional DC motors due to the use of rare-earth magnets and sophisticated electronic controllers. Despite the upfront expense, PMSMs offer lower operational and maintenance costs because of their higher efficiency and reduced wear from the absence of brushes. When evaluating overall lifecycle expenses, PMSMs can be more cost-effective in applications demanding energy savings and long-term reliability.

Application Suitability: Choosing Between PMSM and DC Motor

Permanent Magnet Synchronous Motors (PMSMs) are ideal for applications requiring high efficiency, precise speed control, and compact design, such as electric vehicles and robotics. DC motors excel in simpler, low-cost applications where variable speed control and high starting torque are crucial, including small appliances and basic industrial machinery. Selecting between PMSM and DC motor depends on the specific requirements of power density, control complexity, and operational environment.

Future Trends in Electric Motor Technologies

Permanent Magnet Synchronous Motors (PMSMs) offer higher efficiency, greater power density, and improved thermal performance compared to traditional DC motors, making them ideal for advanced electric vehicle applications. Future trends in electric motor technologies emphasize the integration of rare-earth-free magnets, enhanced inverter control algorithms, and the use of wide-bandgap semiconductors to boost PMSM performance and reduce reliance on critical materials. Emerging solutions in PMSM design target reduced cost, increased energy efficiency, and enhanced reliability, driving widespread adoption in transportation, robotics, and renewable energy sectors.

PMSM, DC Motor Infographic

libterm.com

libterm.com