The electrostrictive effect is a property of certain dielectric materials that causes them to change shape or dimensions in response to an applied electric field, resulting in precise mechanical deformation. This nonlinear phenomenon is widely utilized in sensors, actuators, and energy harvesting devices due to its high sensitivity and stability under varying field strengths. Discover how the electrostrictive effect can enhance your applications by exploring the detailed mechanisms and examples in the rest of this article.

Table of Comparison

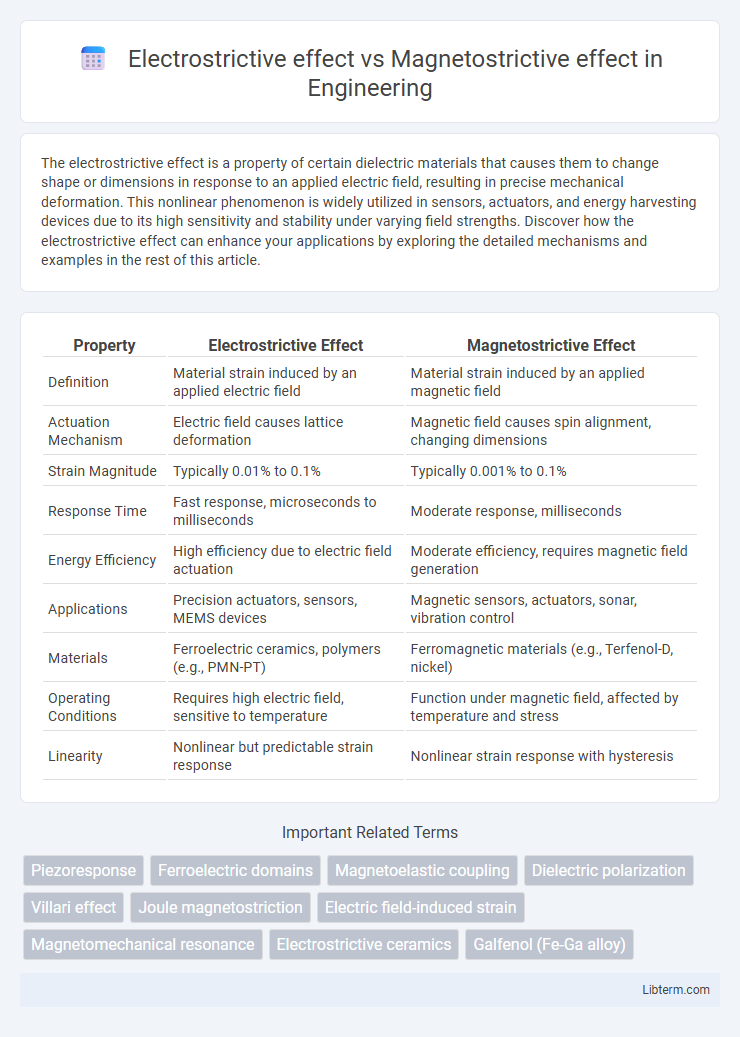

| Property | Electrostrictive Effect | Magnetostrictive Effect |

|---|---|---|

| Definition | Material strain induced by an applied electric field | Material strain induced by an applied magnetic field |

| Actuation Mechanism | Electric field causes lattice deformation | Magnetic field causes spin alignment, changing dimensions |

| Strain Magnitude | Typically 0.01% to 0.1% | Typically 0.001% to 0.1% |

| Response Time | Fast response, microseconds to milliseconds | Moderate response, milliseconds |

| Energy Efficiency | High efficiency due to electric field actuation | Moderate efficiency, requires magnetic field generation |

| Applications | Precision actuators, sensors, MEMS devices | Magnetic sensors, actuators, sonar, vibration control |

| Materials | Ferroelectric ceramics, polymers (e.g., PMN-PT) | Ferromagnetic materials (e.g., Terfenol-D, nickel) |

| Operating Conditions | Requires high electric field, sensitive to temperature | Function under magnetic field, affected by temperature and stress |

| Linearity | Nonlinear but predictable strain response | Nonlinear strain response with hysteresis |

Introduction to Electrostriction and Magnetostriction

Electrostriction is the property of dielectric materials to change shape or dimensions under an applied electric field, typically observed in ferroelectric ceramics and polymers. Magnetostriction refers to the change in shape or dimensions of ferromagnetic materials when exposed to a magnetic field, commonly seen in materials like nickel, iron, and Terfenol-D. Both effects involve strain generation, but electrostriction arises from electric polarization, whereas magnetostriction results from the alignment of magnetic domains.

Underlying Principles of Electrostrictive and Magnetostrictive Effects

The electrostrictive effect arises from the quadratic relationship between electric field and strain in certain dielectric materials, where polarization induces a reversible deformation without polarity dependence. The magnetostrictive effect results from the alignment of magnetic domains in ferromagnetic materials under an external magnetic field, causing a change in shape or dimension due to magnetoelastic coupling. Both phenomena involve coupling between physical fields and mechanical strain, but electrostriction is driven by electric polarization, while magnetostriction is governed by magnetic domain reorientation.

Material Basis: Key Substances Exhibiting Each Effect

Electrostrictive effect primarily occurs in ferroelectric materials such as lead zirconate titanate (PZT) and barium titanate, where the polarization-induced strain results from the reorientation of electric dipoles under an electric field. Magnetostrictive effect is predominantly observed in ferromagnetic materials like Terfenol-D (an alloy of terbium, dysprosium, and iron) and nickel, where the magnetic domain realignment causes measurable changes in shape or dimensions under a magnetic field. Both effects rely on intrinsic material properties, with electrostriction rooted in electric dipole interactions and magnetostriction driven by spin alignment in magnetic domains.

Mechanisms of Action: How Electrostriction and Magnetostriction Work

Electrostriction occurs when a material's dielectric polarization induces a quadratic strain proportional to the square of the applied electric field, resulting from the alignment of electric dipoles within the crystal lattice. Magnetostriction involves the change in shape or dimensions of a ferromagnetic material caused by the reorientation of magnetic domains under an applied magnetic field, altering the magnetoelastic energy state. Both effects rely on intrinsic coupling between electromagnetic fields and lattice deformation, but electrostriction is primarily driven by electric dipole interactions, whereas magnetostriction depends on magnetic domain dynamics and spin-lattice coupling.

Differences in Physical Parameters and Stimuli

The electrostrictive effect involves a material undergoing reversible deformation when subjected to an electric field, characterized by parameters such as electric field strength and dielectric constant. In contrast, the magnetostrictive effect occurs when a material changes shape or dimensions in response to a magnetic field, governed by magnetic field intensity and magnetic permeability. Electrostriction typically requires alternating electric fields for actuation, while magnetostriction depends on variations in magnetic flux density to induce mechanical strain.

Applications of Electrostrictive Materials

Electrostrictive materials exhibit dimensional changes under electric fields, making them ideal for use in precision actuators, sensors, and adaptive optics where fine displacement control is crucial. Unlike magnetostrictive materials that respond to magnetic fields and are prevalent in sonar and vibration control, electrostrictive materials find applications in micro-positioning devices, ultrasonic transducers, and energy harvesting systems due to their high sensitivity and fast response. Their stable operation at high frequencies and ability to generate precise mechanical strain enable advancements in medical imaging and nanopositioning technologies.

Applications of Magnetostrictive Materials

Magnetostrictive materials are widely used in applications such as precision actuators, sensors, and ultrasonic transducers due to their ability to change shape under magnetic fields. These materials enable efficient vibration control and energy harvesting in industrial and aerospace systems. Their high sensitivity and mechanical robustness make them ideal for nondestructive testing and sonar technology.

Comparative Analysis: Performance and Efficiency

Electrostrictive effect exhibits higher precision in strain response under varying electric fields, making it ideal for micro-actuators, while magnetostrictive effect generally offers greater mechanical robustness and larger strain outputs suitable for heavy-duty applications. Efficiency of electrostrictive materials tends to be higher in low-field operations with faster response times, whereas magnetostrictive materials excel in high-field environments but may incur energy losses due to magnetic hysteresis. Comparative performance metrics highlight that electrostrictive devices outperform in miniaturized, low-power applications, whereas magnetostrictive actuators dominate in industrial-scale, high-force settings.

Recent Advances and Research Trends

Recent advances in the electrostrictive effect highlight enhanced material compositions such as lead-free perovskite ceramics, improving strain response under electric fields for actuators and sensors. Magnetostrictive effect research trends emphasize the development of rare-earth-free alloy systems like Fe-Ga and Fe-Al for sustainable and cost-effective magneto-mechanical energy harvesting applications. Cutting-edge studies integrate nanostructuring and computational modeling to optimize the coupling efficiency and durability of both electrostrictive and magnetostrictive materials in advanced multifunctional devices.

Future Prospects in Smart Material Technologies

The electrostrictive effect, characterized by strain response to electric fields, offers high-precision actuation suitable for microelectromechanical systems (MEMS) and advanced sensors, positioning it as a critical technology in future smart material applications. Magnetostrictive materials, which deform under magnetic fields, enable robust energy harvesting and wireless sensing, making them ideal for harsh environment monitoring and adaptive structures. Emerging research on hybrid systems combining electrostrictive and magnetostrictive properties aims to enhance multifunctionality and efficiency, driving innovation in next-generation adaptive and self-powered smart materials.

Electrostrictive effect Infographic

libterm.com

libterm.com