JIT (Just-In-Time) improves efficiency by reducing inventory waste and streamlining production processes, while TOC (Theory of Constraints) focuses on identifying and managing the most critical bottleneck limiting overall system performance. Together, these methodologies enhance operational productivity and ensure smoother workflow in manufacturing and business environments. Discover how combining JIT and TOC strategies can optimize your processes and maximize results in the rest of this article.

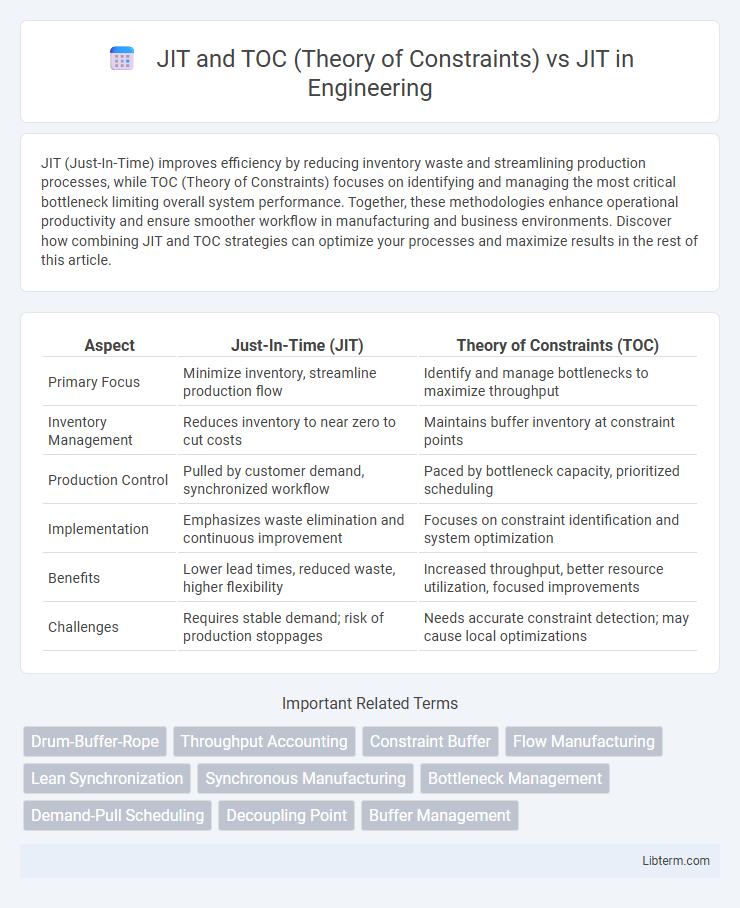

Table of Comparison

| Aspect | Just-In-Time (JIT) | Theory of Constraints (TOC) |

|---|---|---|

| Primary Focus | Minimize inventory, streamline production flow | Identify and manage bottlenecks to maximize throughput |

| Inventory Management | Reduces inventory to near zero to cut costs | Maintains buffer inventory at constraint points |

| Production Control | Pulled by customer demand, synchronized workflow | Paced by bottleneck capacity, prioritized scheduling |

| Implementation | Emphasizes waste elimination and continuous improvement | Focuses on constraint identification and system optimization |

| Benefits | Lower lead times, reduced waste, higher flexibility | Increased throughput, better resource utilization, focused improvements |

| Challenges | Requires stable demand; risk of production stoppages | Needs accurate constraint detection; may cause local optimizations |

Introduction to JIT and TOC

Just-In-Time (JIT) is an inventory management strategy aimed at reducing waste and improving efficiency by receiving goods only as they are needed in the production process. The Theory of Constraints (TOC) focuses on identifying and managing the most critical limiting factor (constraint) that hinders overall system performance. While JIT emphasizes inventory minimization and flow optimization, TOC prioritizes constraint management to maximize throughput and continuous improvement.

Core Principles of Just-In-Time (JIT)

Just-In-Time (JIT) emphasizes reducing inventory waste by delivering materials exactly when needed through continuous flow and pull-based systems, enhancing production efficiency. The core principles of JIT include eliminating non-value-added activities, maintaining high-quality standards, and fostering supplier relationships for timely deliveries. In contrast, the Theory of Constraints (TOC) focuses on identifying and managing system bottlenecks to improve throughput, making TOC more about optimizing constraint resources rather than just inventory minimization.

Fundamentals of the Theory of Constraints (TOC)

The Theory of Constraints (TOC) focuses on identifying and managing the system's most critical bottleneck to optimize overall throughput, contrasting with Just-In-Time (JIT), which emphasizes waste reduction and inventory minimization. TOC's fundamental principle is that improving the constraint directly increases system performance, using tools like the Five Focusing Steps and drum-buffer-rope scheduling. Unlike JIT, which targets continuous flow and lean operations, TOC prioritizes constraint management to elevate capacity and drive sustainable growth in production environments.

Key Differences Between JIT and TOC

Just-in-Time (JIT) focuses on minimizing inventory and streamlining production processes to reduce waste, emphasizing continuous flow and demand-driven replenishment. The Theory of Constraints (TOC) centers on identifying and managing the system's most critical bottleneck or constraint to optimize overall throughput and performance. Key differences include JIT's goal of inventory reduction and process efficiency, while TOC prioritizes constraint exploitation and system-wide improvement by elevating the bottleneck's capacity.

Process Flow: How JIT and TOC Manage Production

JIT (Just-In-Time) optimizes production by minimizing inventory and aligning raw materials precisely with demand, ensuring smooth, continuous process flow and reducing waste. TOC (Theory of Constraints) focuses on identifying and managing the system's bottleneck to maximize throughput and improve overall production efficiency. While JIT emphasizes supply chain synchronization and waste elimination, TOC prioritizes constraint management to enhance process flow and accelerate production cycles.

Inventory Management Approaches in JIT vs TOC

Inventory management in Just-In-Time (JIT) minimizes stock levels by synchronizing production schedules with demand to reduce waste and carrying costs. In contrast, the Theory of Constraints (TOC) prioritizes managing and protecting critical constraints, often maintaining buffer inventories at bottlenecks to ensure continuous flow and prevent system delays. JIT's lean inventory approach contrasts with TOC's strategic buffer stocks, both aiming to optimize production but differing in inventory deployment and risk management.

Bottleneck Identification and Management

JIT (Just-In-Time) emphasizes minimizing inventory and streamlining production processes, while TOC (Theory of Constraints) focuses explicitly on identifying and managing bottlenecks to improve overall system throughput. TOC uses the Five Focusing Steps, including the critical step of identifying the system's constraint, which governs the pace of production and limits output, whereas JIT may not directly address bottleneck management but targets waste reduction and process efficiency. Effective bottleneck identification and management in TOC lead to focused improvements that elevate throughput, contrasting with JIT's broader inventory and workflow optimization strategies.

Advantages and Limitations of JIT

Just-In-Time (JIT) inventory management minimizes waste and reduces carrying costs by synchronizing production with demand, enhancing efficiency and cash flow. Its advantages include lower inventory levels, reduced storage costs, and increased responsiveness to market changes. Limitations of JIT involve vulnerability to supply chain disruptions, limited flexibility in handling demand spikes, and dependency on reliable supplier performance.

Benefits and Challenges of Implementing TOC

The Theory of Constraints (TOC) enhances Just-In-Time (JIT) by addressing system bottlenecks to improve overall throughput, inventory management, and operational efficiency. Implementing TOC offers benefits such as targeted process improvement, reduced lead times, and increased production flow, but challenges include identifying true constraints, aligning cross-functional teams, and managing resistance to change. Successful TOC deployment requires continuous monitoring and iterative adjustments to sustain improvements and maximize value across the supply chain.

Choosing Between JIT, TOC, or Integrating Both

Choosing between Just-In-Time (JIT) and the Theory of Constraints (TOC) involves evaluating operational bottlenecks and inventory management needs; JIT excels in reducing waste and inventory holding costs, while TOC targets system constraints to optimize throughput. Integrating both approaches can enhance production efficiency by focusing on continuous flow and constraint-driven improvements simultaneously. Decision-makers should assess production variability, demand patterns, and system constraints to determine the optimal strategy or combination for maximizing productivity.

JIT and TOC (Theory of Constraints) Infographic

libterm.com

libterm.com