Hot-dip coating involves immersing metal, typically steel or iron, into molten zinc to create a durable, corrosion-resistant layer that extends the material's lifespan. This process enhances your metal's protection against rust and environmental damage, making it ideal for construction, automotive, and industrial applications. Explore the rest of the article to understand how hot-dip coating can benefit your projects and the step-by-step procedure behind this effective treatment.

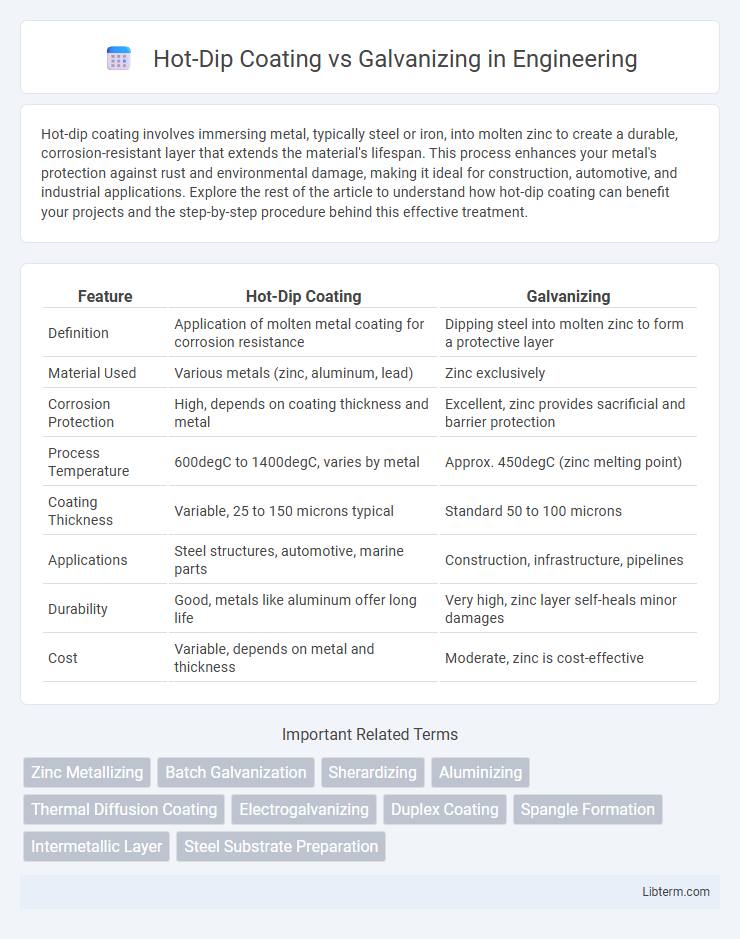

Table of Comparison

| Feature | Hot-Dip Coating | Galvanizing |

|---|---|---|

| Definition | Application of molten metal coating for corrosion resistance | Dipping steel into molten zinc to form a protective layer |

| Material Used | Various metals (zinc, aluminum, lead) | Zinc exclusively |

| Corrosion Protection | High, depends on coating thickness and metal | Excellent, zinc provides sacrificial and barrier protection |

| Process Temperature | 600degC to 1400degC, varies by metal | Approx. 450degC (zinc melting point) |

| Coating Thickness | Variable, 25 to 150 microns typical | Standard 50 to 100 microns |

| Applications | Steel structures, automotive, marine parts | Construction, infrastructure, pipelines |

| Durability | Good, metals like aluminum offer long life | Very high, zinc layer self-heals minor damages |

| Cost | Variable, depends on metal and thickness | Moderate, zinc is cost-effective |

Introduction to Metal Protective Coatings

Hot-dip coating and galvanizing are essential metal protective coatings designed to prevent corrosion and extend the lifespan of steel and iron structures. Hot-dip coating involves immersing metal in molten zinc, creating a robust zinc-iron alloy layer that offers superior adhesion and durability. Galvanizing, a subset of hot-dip coating, specifically refers to zinc coating techniques that provide excellent corrosion resistance through sacrificial protection, making it ideal for outdoor and industrial applications.

Understanding Hot-Dip Coating

Hot-dip coating involves immersing steel or iron into molten zinc, creating a durable, corrosion-resistant layer that bonds metallurgically with the substrate. This process forms a thick, uniform coating that significantly enhances the metal's lifespan in harsh environments by preventing rust and abrasion. Unlike galvanizing methods relying on electroplating, hot-dip coating ensures deeper zinc penetration and superior protection for industrial and construction applications.

What is Galvanizing?

Galvanizing is a metal protection process that involves applying a layer of zinc to steel or iron to prevent corrosion and increase durability. The most common method, hot-dip galvanizing, submerges the metal in molten zinc, creating a strong, long-lasting barrier against rust. This zinc coating not only shields the base metal from environmental damage but also provides sacrificial protection, corroding first to preserve the integrity of the underlying steel or iron.

Key Differences Between Hot-Dip Coating and Galvanizing

Hot-dip coating involves immersing metal into a molten protective layer, often zinc, to form a durable bond, while galvanizing specifically refers to the application of a zinc coating to prevent corrosion. The primary difference lies in the material used and the process control, with galvanizing providing a uniform zinc layer optimized for rust resistance, whereas hot-dip coating can use various metals or alloys for specialized protection. Durability and thickness of the coating vary, with galvanizing typically offering thicker, more consistent coverage essential for industrial and structural steel applications.

Advantages of Hot-Dip Coating

Hot-dip coating offers superior corrosion resistance by immersing steel in molten zinc, creating a robust metallurgical bond that exceeds traditional galvanizing methods in durability. This process provides thick, uniform zinc layers that enhance protection against harsh environmental conditions, extending the lifespan of coated materials. Hot-dip coating also improves abrasion resistance and offers better self-healing properties, reducing maintenance costs and enhancing long-term performance in industrial applications.

Benefits of Galvanizing

Galvanizing provides superior corrosion resistance due to the formation of a robust zinc coating that protects steel from rust and environmental damage. The process extends the lifespan of metal structures significantly, reducing maintenance costs and downtime. Galvanized steel's durability makes it ideal for outdoor applications, including construction, automotive, and infrastructure projects where long-term protection is critical.

Applications: Where Each Method Excels

Hot-dip coating excels in heavy-duty applications requiring thick, durable corrosion protection, such as infrastructure, bridges, and large steel structures exposed to harsh environments. Galvanizing is ideal for smaller components like fasteners, automotive parts, and metal furniture, offering a thinner but uniform zinc layer that provides excellent protection against rust and wear. Choosing between these methods depends on factors like environmental exposure, component size, and required durability, with hot-dip coating better suited for industrial use and galvanizing preferred for consumer and light industrial products.

Cost Comparison: Hot-Dip Coating vs Galvanizing

Hot-dip coating generally incurs lower initial costs compared to galvanizing due to simpler application processes and reduced labor requirements. Galvanizing, while often more expensive upfront, offers superior long-term corrosion resistance, potentially lowering maintenance and replacement expenses over time. The total cost comparison depends on factors such as project scale, environmental conditions, and expected lifespan, with hot-dip coating favored for budget-sensitive, short-term applications and galvanizing for durable, heavy-duty protection.

Durability and Long-term Performance

Hot-dip coating provides robust corrosion resistance by immersing steel in molten zinc, creating a thick, durable layer that withstands harsh environments and mechanical wear. Galvanizing forms a tightly bonded zinc-iron alloy layer that offers superior long-term protection against rust and weathering, extending the lifespan of steel structures. Both methods enhance durability significantly, but galvanizing typically ensures longer-lasting performance in outdoor and industrial applications.

Choosing the Right Coating for Your Project

Selecting the right coating for your project requires understanding key differences between hot-dip coating and galvanizing, both of which protect steel from corrosion through zinc application. Hot-dip coating involves immersing steel in molten zinc, forming a robust, thick layer ideal for outdoor and industrial environments exposed to harsh elements. Galvanizing typically refers to the hot-dip process but can also include electro-galvanizing, which applies a thinner zinc layer suited for indoor or less aggressive conditions, making the choice dependent on environmental exposure, durability requirements, and budget constraints.

Hot-Dip Coating Infographic

libterm.com

libterm.com