Roller bearings are essential components designed to reduce friction and support radial and axial loads in machinery, enhancing operational efficiency and durability. Their robust construction allows them to manage heavy loads and high speeds, making them ideal for various industrial applications. Discover how selecting the right roller bearing can improve your equipment's performance in the rest of this article.

Table of Comparison

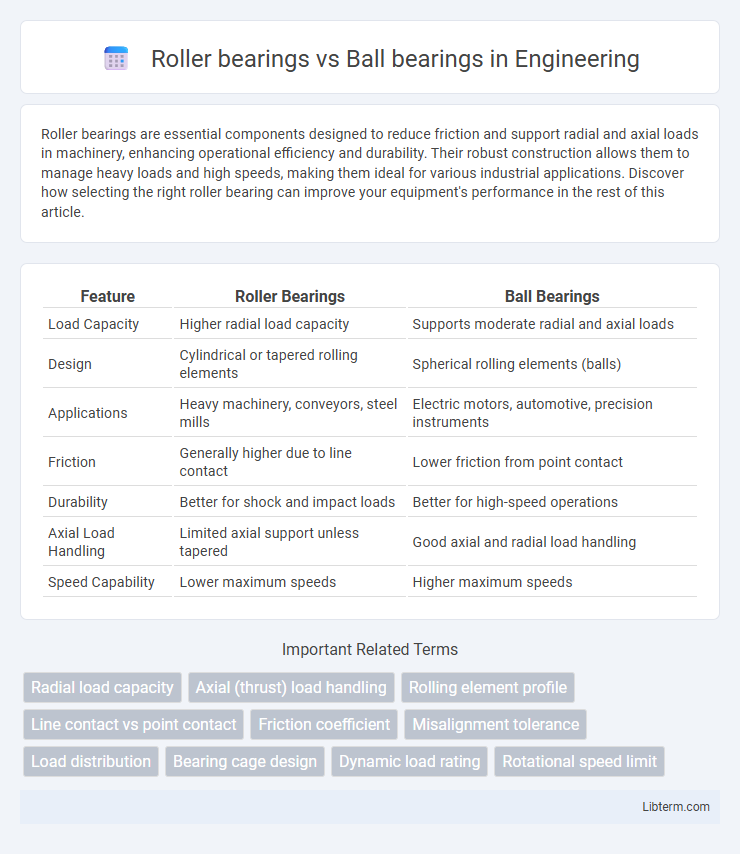

| Feature | Roller Bearings | Ball Bearings |

|---|---|---|

| Load Capacity | Higher radial load capacity | Supports moderate radial and axial loads |

| Design | Cylindrical or tapered rolling elements | Spherical rolling elements (balls) |

| Applications | Heavy machinery, conveyors, steel mills | Electric motors, automotive, precision instruments |

| Friction | Generally higher due to line contact | Lower friction from point contact |

| Durability | Better for shock and impact loads | Better for high-speed operations |

| Axial Load Handling | Limited axial support unless tapered | Good axial and radial load handling |

| Speed Capability | Lower maximum speeds | Higher maximum speeds |

Introduction to Rolling Element Bearings

Rolling element bearings encompass both roller bearings and ball bearings, designed to reduce rotational friction and support loads by using rolling elements between bearing races. Roller bearings utilize cylindrical or tapered rollers to handle heavier radial and axial loads, offering enhanced load capacity compared to ball bearings. Ball bearings employ spherical balls that excel in managing lower load capacities with reduced friction and higher speed capabilities, making each type suited to specific industrial applications based on load, speed, and alignment requirements.

What Are Roller Bearings?

Roller bearings use cylindrical or tapered rolling elements to support radial and axial loads, providing higher load capacity compared to ball bearings due to increased contact area. They are ideal for heavy-duty applications such as conveyor belts, automotive wheels, and industrial machinery where durability and load distribution are critical. Roller bearings reduce friction and wear, enhancing machine efficiency and lifespan under high-stress conditions.

What Are Ball Bearings?

Ball bearings are mechanical components designed to reduce friction and support radial and axial loads by using balls as the rolling elements between inner and outer rings. These bearings enable smooth rotational motion and are commonly used in applications such as electric motors, bicycles, and automotive wheels. Their design allows for high-speed operation and precise alignment, making them ideal for low to moderate load conditions.

Design Differences: Roller vs. Ball Bearings

Roller bearings feature cylindrical or tapered rolling elements designed to handle heavier radial loads and better distribute stress over a larger contact area compared to ball bearings. Ball bearings utilize spherical balls that provide lower friction and support both radial and axial loads, making them ideal for high-speed applications with lighter load requirements. The design difference fundamentally affects load capacity, friction levels, and the types of applications suited for each bearing type.

Load Capacity Comparison

Roller bearings generally offer higher load capacity than ball bearings due to their larger contact area between the rolling elements and raceways, allowing them to better support heavy radial loads. Ball bearings excel in handling both radial and axial loads but have lower load capacity compared to roller bearings due to point contact. Applications requiring heavy load support and durability, such as heavy machinery and conveyor systems, typically prefer roller bearings for optimal performance.

Applications: Where Each Bearing Excels

Roller bearings excel in heavy-load applications such as industrial machinery, conveyor belts, and automotive axles due to their higher radial load capacity and durability under shock and vibration. Ball bearings are ideal for high-speed, precision applications including electric motors, hard drives, and aerospace components, offering lower friction and smoother operation. Choosing between the two depends on factors like load type, speed, and required lifespan, with roller bearings preferred for heavy loads and ball bearings for high-speed, low-load environments.

Durability and Lifespan Analysis

Roller bearings offer superior durability compared to ball bearings due to their larger contact area, which distributes loads more evenly and reduces stress on individual components. This design results in a longer lifespan under heavy load and high-impact conditions, making roller bearings ideal for industrial applications requiring high load capacity and resistance to wear. In contrast, ball bearings excel in reducing friction in lighter load scenarios, but their smaller contact points tend to wear faster, leading to a comparatively shorter operational life.

Efficiency and Performance Factors

Roller bearings provide higher load capacity and greater efficiency in handling radial and axial loads compared to ball bearings, making them ideal for heavy-duty applications. Ball bearings excel in high-speed performance due to their lower friction and ability to handle moderate loads with precision. The choice between roller bearings and ball bearings depends on specific performance factors such as load magnitude, speed requirements, and application conditions.

Cost Considerations in Bearing Selection

Roller bearings generally incur higher initial costs than ball bearings due to their complex design and ability to handle heavier loads, which can increase overall operational efficiency and reduce maintenance expenses in demanding applications. Ball bearings offer a cost-effective solution for lighter loads and high-speed operations, making them ideal for everyday machinery where budget constraints are critical. Selecting the right bearing requires balancing upfront investment against longevity and performance to optimize total cost of ownership.

Choosing the Right Bearing for Your Needs

Roller bearings provide higher load capacity and better performance in applications with heavy radial loads, while ball bearings excel in handling both radial and axial loads with lower friction and greater precision. Selecting the right bearing depends on factors such as load type, speed requirements, and environmental conditions, where roller bearings suit heavy-duty machinery and ball bearings are preferable for high-speed, low-load scenarios. Understanding these distinctions ensures optimal efficiency and longevity in mechanical systems across industries.

Roller bearings Infographic

libterm.com

libterm.com