Boiling convection enhances heat transfer by combining fluid motion with phase change, significantly increasing thermal efficiency in systems like heat exchangers and cooling devices. This process involves nucleate boiling, where vapor bubbles form and rise, promoting vigorous mixing and rapid heat dissipation. Discover how boiling convection can optimize your thermal management by exploring the detailed mechanisms and practical applications in the rest of this article.

Table of Comparison

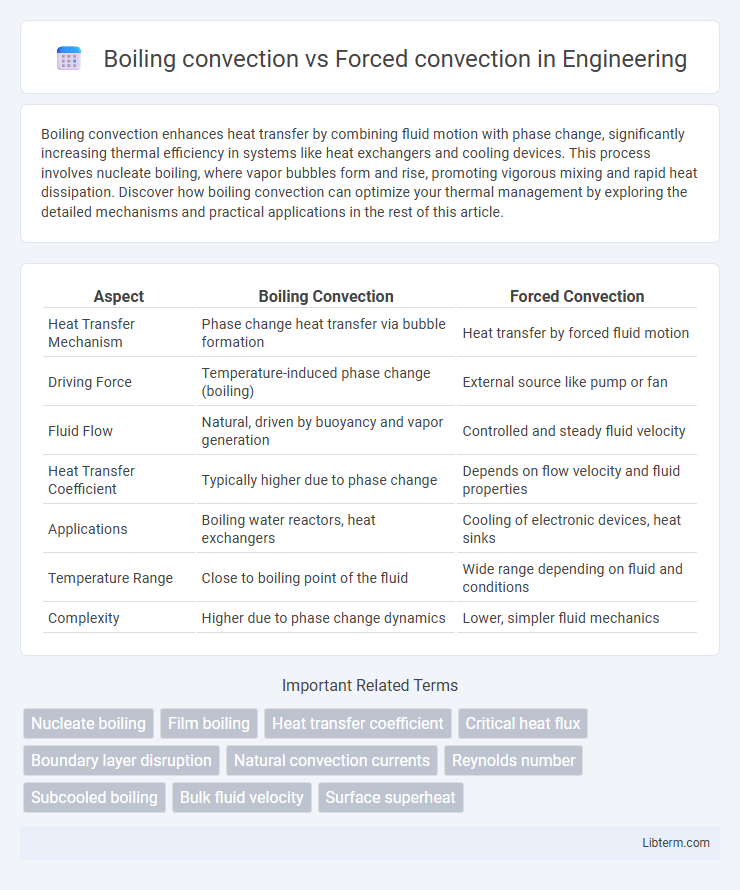

| Aspect | Boiling Convection | Forced Convection |

|---|---|---|

| Heat Transfer Mechanism | Phase change heat transfer via bubble formation | Heat transfer by forced fluid motion |

| Driving Force | Temperature-induced phase change (boiling) | External source like pump or fan |

| Fluid Flow | Natural, driven by buoyancy and vapor generation | Controlled and steady fluid velocity |

| Heat Transfer Coefficient | Typically higher due to phase change | Depends on flow velocity and fluid properties |

| Applications | Boiling water reactors, heat exchangers | Cooling of electronic devices, heat sinks |

| Temperature Range | Close to boiling point of the fluid | Wide range depending on fluid and conditions |

| Complexity | Higher due to phase change dynamics | Lower, simpler fluid mechanics |

Introduction to Heat Transfer Mechanisms

Boiling convection involves heat transfer through phase change where a liquid absorbs heat and vaporizes, creating bubbles that enhance thermal energy transfer at the surface. Forced convection relies on external fluid motion, such as pumps or fans, to increase heat transfer rates by continuously moving the fluid over the heated or cooled surface. Understanding these mechanisms is critical in designing efficient thermal management systems in industries like power generation, electronics cooling, and chemical processing.

Overview of Boiling Convection

Boiling convection occurs when a liquid reaches its boiling point and vapor bubbles form at the heated surface, enhancing heat transfer through phase change. This mechanism significantly increases the heat transfer coefficient compared to single-phase forced convection, especially in applications like heat exchangers and cooling systems. The intensity of boiling convection depends on surface temperature, pressure, and fluid properties, making it crucial for efficient thermal management in industrial processes.

Understanding Forced Convection

Forced convection involves the movement of fluid induced by external forces such as fans, pumps, or blowers, significantly enhancing heat transfer rates compared to natural convection. This process relies on the velocity and properties of the fluid to control the heat exchange between surfaces and the fluid, enabling applications like cooling in electronic devices or heating in industrial processes. Understanding forced convection requires analyzing parameters such as Reynolds number, Nusselt number, and Prandtl number to optimize the convective heat transfer coefficient effectively.

Key Differences Between Boiling and Forced Convection

Boiling convection involves phase change from liquid to vapor occurring at a heated surface, resulting in high heat transfer rates due to bubble formation and latent heat. Forced convection relies on external means such as fans or pumps to enhance fluid motion, increasing heat transfer without phase change. Boiling convection typically exhibits higher heat transfer coefficients and critical heat flux phenomena, whereas forced convection is dominated by fluid velocity, temperature gradients, and flow regime effects.

Heat Transfer Efficiency Comparison

Boiling convection achieves significantly higher heat transfer efficiency than forced convection due to phase change, which absorbs large amounts of latent heat, enhancing thermal energy removal. Forced convection relies solely on fluid velocity and temperature difference, limiting its heat transfer rate compared to boiling, especially at high heat fluxes. Consequently, boiling convection is preferred in applications requiring rapid and efficient thermal management, such as in heat exchangers and cooling systems for electronic devices.

Applications of Boiling Convection

Boiling convection is widely utilized in industrial applications such as heat exchangers, nuclear reactors, and refrigeration systems due to its high heat transfer efficiency during phase change. It enhances cooling performance in power plants by rapidly removing heat from reactor cores, preventing overheating and improving safety. This mode of convection is crucial in processes requiring efficient thermal management, especially where maintaining fluid temperature near boiling point optimizes energy transfer.

Applications of Forced Convection

Forced convection finds extensive applications in industries such as HVAC systems for climate control, automotive engine cooling to maintain optimal temperatures, and electronic device cooling to prevent overheating. It is crucial in heat exchangers and industrial processes where controlled heat transfer enhances efficiency, such as chemical reactors and power plants. Efficient forced convection systems improve energy consumption and operational reliability across these varied applications.

Factors Affecting Convection Performance

Boiling convection performance is primarily influenced by surface temperature, fluid properties, and bubble formation dynamics, which enhance heat transfer through phase change. Forced convection depends on fluid velocity, viscosity, and flow regime, where increased velocity improves heat transfer rates by reducing thermal boundary layers. Both convection types are affected by pressure, surface roughness, and fluid thermal conductivity, but boiling convection benefits more significantly from nucleate boiling conditions for optimal performance.

Challenges and Limitations

Boiling convection faces challenges such as surface fouling, bubble departure dynamics, and critical heat flux limitations that restrict efficient heat transfer at high heat fluxes. Forced convection encounters limitations including increased pressure drop, flow-induced vibrations, and scaling issues that affect system performance and reliability. Both convection modes require careful optimization to balance thermal efficiency with operational stability in engineering applications.

Conclusion and Future Perspectives

Boiling convection offers efficient heat transfer through phase change but is limited by surface conditions and critical heat flux challenges. Forced convection enables controlled thermal management via fluid motion but often requires higher energy input and complex system design. Future research aims to integrate nanofluids, optimized surface coatings, and hybrid convection systems to enhance overall heat transfer performance and energy efficiency in industrial applications.

Boiling convection Infographic

libterm.com

libterm.com