The proportional limit marks the maximum stress a material can withstand while maintaining a linear relationship between stress and strain, crucial for predicting structural behavior. Understanding this limit helps engineers ensure safety and prevent permanent deformation in materials under load. Explore the article to learn how the proportional limit impacts material selection and design decisions in your projects.

Table of Comparison

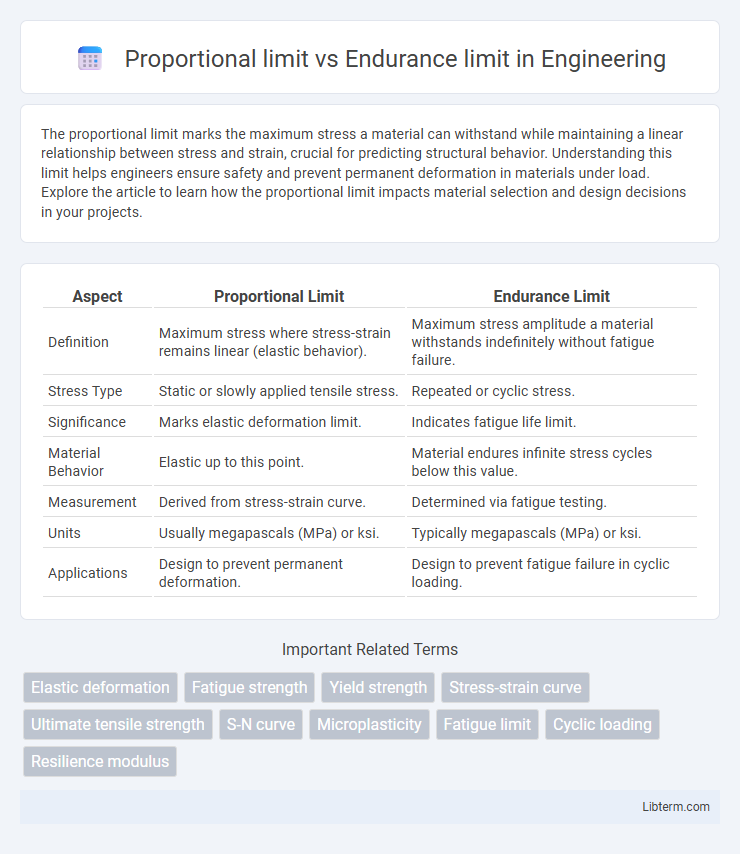

| Aspect | Proportional Limit | Endurance Limit |

|---|---|---|

| Definition | Maximum stress where stress-strain remains linear (elastic behavior). | Maximum stress amplitude a material withstands indefinitely without fatigue failure. |

| Stress Type | Static or slowly applied tensile stress. | Repeated or cyclic stress. |

| Significance | Marks elastic deformation limit. | Indicates fatigue life limit. |

| Material Behavior | Elastic up to this point. | Material endures infinite stress cycles below this value. |

| Measurement | Derived from stress-strain curve. | Determined via fatigue testing. |

| Units | Usually megapascals (MPa) or ksi. | Typically megapascals (MPa) or ksi. |

| Applications | Design to prevent permanent deformation. | Design to prevent fatigue failure in cyclic loading. |

Understanding the Proportional Limit

The proportional limit defines the maximum stress a material can withstand while maintaining a linear stress-strain relationship, marking the end of elastic behavior. Unlike the endurance limit, which indicates the stress level below which a material can endure infinite loading cycles without failure, the proportional limit is crucial for determining safe load limits to prevent permanent deformation. Understanding the proportional limit helps engineers design structures that avoid yielding and ensures materials return to their original shape after unloading.

Defining the Endurance Limit

The endurance limit is the maximum stress level a material can withstand indefinitely without experiencing fatigue failure, unlike the proportional limit, which marks the stress threshold within elastic deformation. This critical fatigue parameter is essential for designing components subjected to cyclic loading, ensuring long-term durability by preventing crack initiation and propagation. Accurate determination of the endurance limit involves rigorous fatigue testing under varying stress amplitudes to establish safe operational stress ranges.

Key Differences Between Proportional and Endurance Limits

The proportional limit marks the maximum stress at which a material deforms elastically and stress-strain curve remains linear, while the endurance limit represents the maximum stress a material can withstand indefinitely without fatigue failure. Proportional limit is concerned with elastic behavior under a single load, whereas endurance limit relates to cyclic loading and fatigue resistance over millions of cycles. Unlike the proportional limit, the endurance limit is typically lower and is critical for designing components subject to repeated stress fluctuations.

Significance in Material Science

The proportional limit marks the maximum stress a material can withstand while maintaining a linear stress-strain relationship, crucial for predicting elastic behavior and designing structures within safe load limits. The endurance limit defines the maximum cyclic stress a material can endure indefinitely without failure, essential for assessing fatigue life in components subjected to repetitive loading. Understanding both limits enables engineers to optimize material selection and prevent mechanical failure in static and dynamic applications.

Stress-Strain Relationship Explained

The proportional limit marks the maximum stress at which a material's stress-strain curve remains linear, indicating elastic behavior and a constant ratio of stress to strain. In contrast, the endurance limit defines the maximum stress a material can withstand indefinitely without fatigue failure under cyclic loading. Understanding the difference between these limits is crucial for designing components subjected to static loads versus repeated stress cycles, ensuring safety and durability in engineering applications.

Testing Methods for Proportional and Endurance Limits

Tensile testing determines the proportional limit by gradually applying load until the stress-strain curve deviates from linearity, indicating the end of elastic behavior. Endurance limit testing involves repeated cyclic loading using a fatigue testing machine to identify the maximum stress level a material can withstand indefinitely without failure. Strain gauges and extensometers precisely measure deformation during proportional limit tests, while load-controlled fatigue testers track failure cycles for endurance limit assessment.

Applications in Engineering Design

The proportional limit defines the maximum stress a material can endure while maintaining a linear elastic relationship between stress and strain, crucial for ensuring structural components behave predictably under load. The endurance limit, or fatigue limit, represents the maximum stress level a material can withstand indefinitely without failure, essential for designing components subjected to cyclic loading such as bridges and rotating machinery. Engineering design utilizes the proportional limit to prevent permanent deformation, while the endurance limit guides fatigue life assessments, enabling safer and more durable product development.

Factors Influencing Each Limit

The proportional limit is influenced primarily by material composition, microstructure, and temperature, which affect the initial elastic behavior of metals before permanent deformation. The endurance limit depends on factors such as surface finish, size, temperature, stress concentration, and cyclic loading conditions, determining the stress amplitude a material can withstand for infinite fatigue life. Both limits are sensitive to environmental conditions, but fatigue mechanisms play a more critical role in defining the endurance limit compared to the proportional limit.

Real-World Examples and Case Studies

The proportional limit marks the maximum stress a material can withstand while maintaining a linear relationship between stress and strain, as demonstrated in steel beams used in bridge construction where exceeding this limit causes permanent deformation. The endurance limit refers to the maximum stress a material can endure for infinite cycles without failure, highlighted by fatigue testing in airplane wing components subjected to repeated loading during flights. Case studies of aircraft landing gear show materials designed with endurance limits to prevent catastrophic failure under cyclic stress, emphasizing the critical role of these limits in ensuring structural safety and longevity.

Conclusion: Choosing the Right Limit for Analysis

The proportional limit defines the maximum stress a material can withstand while maintaining linear elasticity, critical for initial design safety margins. The endurance limit represents the stress threshold below which a material can endure infinite cycles without failure, essential for fatigue analysis in cyclic loading conditions. Selecting the appropriate limit depends on the application: proportional limit for static loads and endurance limit for components subjected to repeated stress variations.

Proportional limit Infographic

libterm.com

libterm.com