Valve timing controls the precise opening and closing of an engine's intake and exhaust valves, crucial for optimizing combustion efficiency and engine performance. Proper valve timing enhances fuel economy, reduces emissions, and increases power output by ensuring the air-fuel mixture and exhaust gases flow at the right moments. Discover how precise valve timing can transform your engine's performance by reading the full article.

Table of Comparison

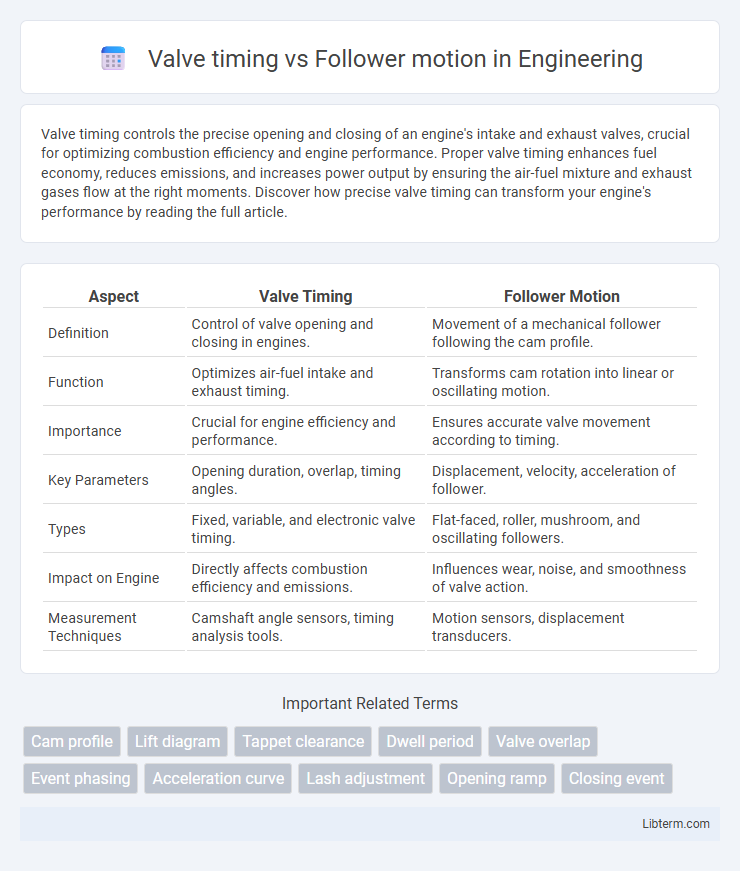

| Aspect | Valve Timing | Follower Motion |

|---|---|---|

| Definition | Control of valve opening and closing in engines. | Movement of a mechanical follower following the cam profile. |

| Function | Optimizes air-fuel intake and exhaust timing. | Transforms cam rotation into linear or oscillating motion. |

| Importance | Crucial for engine efficiency and performance. | Ensures accurate valve movement according to timing. |

| Key Parameters | Opening duration, overlap, timing angles. | Displacement, velocity, acceleration of follower. |

| Types | Fixed, variable, and electronic valve timing. | Flat-faced, roller, mushroom, and oscillating followers. |

| Impact on Engine | Directly affects combustion efficiency and emissions. | Influences wear, noise, and smoothness of valve action. |

| Measurement Techniques | Camshaft angle sensors, timing analysis tools. | Motion sensors, displacement transducers. |

Introduction to Valve Timing and Follower Motion

Valve timing controls the opening and closing of engine valves, directly affecting airflow and combustion efficiency in internal combustion engines. Follower motion describes the movement of the cam follower, which translates camshaft rotation into valve motion, influencing valve lift and duration. Precise synchronization of valve timing and follower motion maximizes engine performance, fuel efficiency, and emissions control.

Fundamentals of Valve Timing in Engine Operation

Valve timing in engine operation determines the precise opening and closing of intake and exhaust valves, optimizing airflow and combustion efficiency. The follower motion translates the camshaft's rotational movement into linear motion, controlling valve lift and duration for accurate timing. Proper synchronization between valve timing and follower motion ensures maximum engine performance, fuel economy, and reduced emissions.

Overview of Follower Motion Mechanisms

Follower motion mechanisms convert rotary motion into precise linear or oscillatory movements essential for valve timing in engines. Common designs include cam-follower systems where the camshaft profile dictates valve opening and closing sequences, directly influencing engine efficiency and performance. Optimizing follower motion reduces wear and vibration, ensuring accurate valve timing and enhancing combustion control.

Key Differences Between Valve Timing and Follower Motion

Valve timing controls the precise opening and closing of engine valves to optimize air-fuel mixture intake and exhaust expulsion, directly affecting engine efficiency and power output. Follower motion describes the movement pattern of the valve lifter or tappet within the cam mechanism, influencing the smoothness and accuracy of valve actuation. Key differences lie in valve timing's role in synchronization and combustion performance, whereas follower motion pertains to the mechanical transmission of camshaft motion to the valves.

Importance of Precise Valve Timing

Precise valve timing is critical in optimizing engine performance by ensuring valves open and close at exact intervals to maximize air-fuel mixture intake and exhaust gas expulsion. Accurate synchronization between valve timing and follower motion reduces engine wear, enhances fuel efficiency, and improves power output by maintaining optimal combustion conditions. Deviations in valve timing can lead to incomplete combustion, increased emissions, and mechanical failures, emphasizing the importance of precise control in high-performance engines.

Influence of Follower Motion on Engine Performance

Follower motion directly impacts valve timing accuracy, influencing engine breathing efficiency and power output. Rapid acceleration or deceleration of the follower can cause valve float or bounce, reducing combustion chamber sealing and causing performance losses. Optimizing follower kinematics minimizes wear and ensures precise valve events, enhancing overall engine responsiveness and fuel efficiency.

Common Valve Timing Strategies

Common valve timing strategies such as cam timing, variable valve timing (VVT), and exhaust valve overlap optimize engine performance by precisely controlling valve opening and closing intervals. Cam timing uses fixed profiles for valve operation, while VVT adjusts valve timing dynamically based on engine speed and load to improve fuel efficiency and power output. Exhaust valve overlap enhances scavenging by allowing exhaust gases to exit while intake valves open, contributing to better combustion and reduced emissions.

Types of Follower Motion Profiles

Valve timing significantly influences engine performance through the use of various follower motion profiles, such as uniform velocity, simple harmonic, and uniform acceleration and retardation motion. Simple harmonic motion is widely favored for its smooth acceleration characteristics, reducing wear and vibration, while uniform velocity profiles provide consistent speed but can cause abrupt impacts. Uniform acceleration and retardation motion offers a balanced approach, optimizing valve opening and closing for enhanced combustion efficiency and mechanical longevity.

Impact of Valve Timing and Follower Motion on Emissions and Efficiency

Valve timing significantly influences engine efficiency and emissions by controlling the precise opening and closing of intake and exhaust valves, optimizing air-fuel mixture flow and combustion. Follower motion affects cam profile accuracy and valve lift consistency, impacting the sealing efficiency and reducing valve train friction, which in turn enhances fuel economy and lowers pollutant output. Optimized valve timing combined with precise follower motion reduces unburned hydrocarbons and NOx emissions, improving overall engine performance and environmental compliance.

Future Trends in Valve Timing and Follower Motion Technologies

Future trends in valve timing technologies emphasize variable valve timing (VVT) systems enhanced by artificial intelligence and machine learning algorithms to optimize engine efficiency and emissions dynamically. Advanced follower motion mechanisms are being developed with lightweight, wear-resistant materials and precision manufacturing techniques to reduce friction and improve durability in high-performance engines. Integration of electromagnetic and electrohydraulic actuators promises faster, more accurate valve control, supporting the shift toward electrification and hybrid powertrains.

Valve timing Infographic

libterm.com

libterm.com