Plug welds create strong, permanent joints by filling holes in one metal piece to fuse it with another underneath. This welding technique is ideal for connecting overlapping sheets or reinforcing structures where traditional welds may be impractical. Explore the rest of this article to understand how plug welds can enhance your metalworking projects with durability and precision.

Table of Comparison

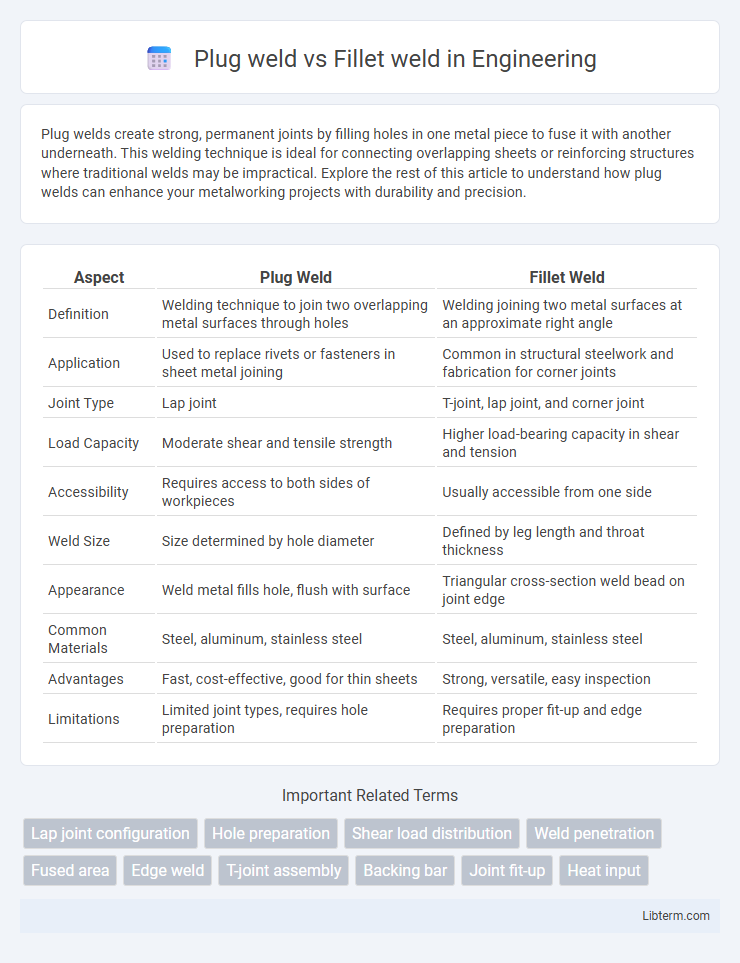

| Aspect | Plug Weld | Fillet Weld |

|---|---|---|

| Definition | Welding technique to join two overlapping metal surfaces through holes | Welding joining two metal surfaces at an approximate right angle |

| Application | Used to replace rivets or fasteners in sheet metal joining | Common in structural steelwork and fabrication for corner joints |

| Joint Type | Lap joint | T-joint, lap joint, and corner joint |

| Load Capacity | Moderate shear and tensile strength | Higher load-bearing capacity in shear and tension |

| Accessibility | Requires access to both sides of workpieces | Usually accessible from one side |

| Weld Size | Size determined by hole diameter | Defined by leg length and throat thickness |

| Appearance | Weld metal fills hole, flush with surface | Triangular cross-section weld bead on joint edge |

| Common Materials | Steel, aluminum, stainless steel | Steel, aluminum, stainless steel |

| Advantages | Fast, cost-effective, good for thin sheets | Strong, versatile, easy inspection |

| Limitations | Limited joint types, requires hole preparation | Requires proper fit-up and edge preparation |

Introduction to Plug Welds and Fillet Welds

Plug welds are circular welds used to join two overlapping metal pieces by filling a drilled hole in the top piece, providing strong shear resistance and eliminating the need for edge preparation. Fillet welds are triangular welds that join two surfaces at a right angle, commonly used in lap, T, and corner joints to provide structural strength and seal the joint from environmental exposure. Both weld types are essential in fabrication and construction, with plug welds typically applied for joining sheet metals and fillet welds for creating corner or edge reinforcements.

Definition and Key Features of Plug Welds

Plug welds are circular welds used to join two overlapping metal pieces by filling a pre-drilled hole in the top piece with weld metal, creating a strong bond through fusion. Key features of plug welds include their ability to provide shear strength similar to spot welds, minimize material distortion, and are often used when access to both sides of the joint is limited. Unlike fillet welds, which join two adjacent surfaces at a right angle, plug welds fill through-holes and are ideal for joining sheet metals in automotive and construction applications.

Definition and Key Features of Fillet Welds

Fillet welds are a type of weld used to join two surfaces at a right angle or an approximate angle, typically in T, lap, or corner joint configurations. They are characterized by their triangular cross-section, providing a strong bond between the connected metal pieces without requiring edge preparation. Fillet welds are versatile, commonly applied in structural steel fabrication, shipbuilding, and pipeline construction due to their ease of application and effective load distribution.

Applications of Plug Welds in Industry

Plug welds provide strong, fatigue-resistant joints ideal for joining overlapping metal sheets in automotive manufacturing and heavy machinery assembly. They are frequently used to fasten components where access is restricted to one side, such as in vehicle chassis and structural frames. Their ability to minimize surface distortion and increase load distribution makes plug welds essential for industrial applications requiring durable, concealed connections.

Common Uses of Fillet Welds

Fillet welds are commonly used in structural steel fabrication, joining T-joints, lap joints, and corner joints in construction, shipbuilding, and automotive industries. They provide strong, reliable connections for load-bearing applications and are ideal for welding materials of varying thicknesses without requiring edge preparation. Fillet welds are favored for their ease of application and versatility in joining components at right angles or overlapping surfaces.

Plug Weld vs Fillet Weld: Strength Comparison

Plug welds provide high shear strength by filling holes in overlapping sheets, ensuring solid metal-to-metal bonding ideal for stress-bearing joints. Fillet welds offer strong tensile strength by fusing two surfaces at a right angle, commonly used in structural applications requiring resistance to bending forces. In strength comparison, plug welds excel in shear load scenarios, while fillet welds are superior for withstanding tensile and bending stresses.

Differences in Welding Process and Technique

Plug weld involves filling a circular hole in one metal piece to join it to another, ensuring strong shear strength, whereas fillet weld creates a triangular cross-section along the joint edges. The plug weld process typically requires drilling holes and welding through them, concentrating on fusion within the hole, while fillet weld is performed along the overlapping edges without penetrating holes. Fillet welding is suitable for corner, lap, and tee joints, while plug welding excels in joining sheets where full penetration welds are impractical.

Cost and Time Considerations

Plug welds generally offer lower labor costs and faster completion times compared to fillet welds because they require less edge preparation and can be executed more quickly in confined spaces. Fillet welds, while often providing stronger joints, demand more surface preparation and precision, increasing both material consumption and time investment. Choosing plug welds can optimize project budgets by reducing welding time and minimizing filler metal usage, making them cost-effective for applications where joint strength requirements are moderate.

Inspection and Quality Control

Inspection of plug welds emphasizes verifying weld size, penetration, and absence of voids or cracks through visual inspection and nondestructive testing methods like ultrasonic testing (UT). Fillet weld inspection prioritizes checking leg length, throat thickness, and surface discontinuities using techniques such as magnetic particle testing (MPT) and dye penetrant testing (DPT). Quality control for both weld types involves adherence to AWS D1.1 standards, ensuring proper welding procedure specifications (WPS) and welder qualifications to maintain structural integrity and performance.

Choosing Between Plug Weld and Fillet Weld

Choosing between plug weld and fillet weld depends on the joint design and load requirements; plug welds are ideal for joining overlapping plates where access is limited, providing strong shear resistance through the hole filled with weld metal. Fillet welds excel in T-joints, lap joints, and corner joints, offering ease of application and good strength in both shear and tensile loads along accessible edges. The decision should consider factors like welding position, material thickness, and stress orientation to ensure optimal structural integrity and cost-effectiveness.

Plug weld Infographic

libterm.com

libterm.com