Globe valves provide precise flow control by using a movable plug and a fixed seat within a spherical body, making them ideal for regulating fluid flow in pipelines. Their design ensures reliable sealing and minimal leakage, enhancing safety and efficiency in various industrial applications. Explore this article to understand how a globe valve can optimize your fluid management system.

Table of Comparison

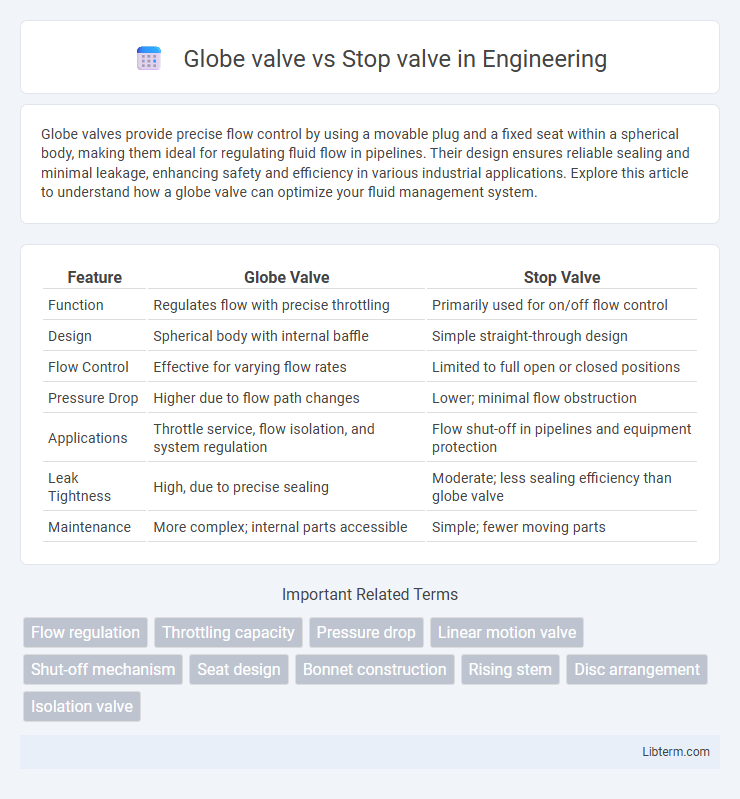

| Feature | Globe Valve | Stop Valve |

|---|---|---|

| Function | Regulates flow with precise throttling | Primarily used for on/off flow control |

| Design | Spherical body with internal baffle | Simple straight-through design |

| Flow Control | Effective for varying flow rates | Limited to full open or closed positions |

| Pressure Drop | Higher due to flow path changes | Lower; minimal flow obstruction |

| Applications | Throttle service, flow isolation, and system regulation | Flow shut-off in pipelines and equipment protection |

| Leak Tightness | High, due to precise sealing | Moderate; less sealing efficiency than globe valve |

| Maintenance | More complex; internal parts accessible | Simple; fewer moving parts |

Introduction to Globe Valves and Stop Valves

Globe valves provide precise flow control, featuring a spherical body and a movable disk that regulates fluid through a linear motion. Stop valves, typically used for simple on-off control, have a straightforward design that allows quick shutoff but limited throttling capabilities. Both valves are essential in fluid handling systems, with globe valves excelling in modulation and stop valves favored for isolating flow.

Key Differences Between Globe Valves and Stop Valves

Globe valves feature a spherical body shape with a movable disk that regulates flow by moving perpendicular to the seat, providing precise throttling and flow control, whereas stop valves primarily function as on/off devices with a simpler design that prioritizes quick shutoff. Globe valves exhibit higher pressure drops due to flow direction changes inside their body, contrasting with stop valves that maintain straighter flow paths and lower pressure losses. Material construction, typical applications, and maintenance complexity also differentiate globe valves, which suit throttling in pipelines, from stop valves favored for isolation and straightforward operation.

Working Principle of Globe Valves

Globe valves operate using a linear motion where a movable disk or plug moves perpendicularly against a stationary ring seat to regulate fluid flow. This precise mechanism allows for efficient throttling and flow control, differentiating it from stop valves that primarily provide on/off functionality by lifting a gate or disk out of the flow path. Globe valves are preferred in applications requiring accurate flow regulation and frequent operation cycles.

Working Mechanism of Stop Valves

Stop valves operate by moving a disc or plug perpendicular to the flow to completely block or allow fluid passage, providing reliable shut-off capabilities. Unlike globe valves, which regulate flow through a spherical body with internal baffles, stop valves achieve flow control primarily through direct closure without flow modulation. The simple linear motion of the stop valve's stem ensures quick operation and tight sealing, making it ideal for emergency shut-off and isolation in piping systems.

Applications of Globe Valves

Globe valves are widely used in applications requiring precise flow control, such as in cooling water systems, fuel oil systems, and feedwater systems in power plants. Their ability to regulate flow with accuracy makes them ideal for throttling services in chemical processing and HVAC systems. Unlike stop valves, globe valves provide better sealing and flow modulation, enhancing their suitability for high-pressure and high-temperature environments.

Applications of Stop Valves

Stop valves are commonly used in plumbing and industrial applications to completely shut off fluid flow in pipelines for maintenance or emergencies. These valves are ideal for systems requiring quick isolation, such as water supply lines, gas pipelines, and steam systems, due to their simple mechanism and tight sealing ability. Their design allows for effective flow control and easy operation in environments where immediate stopping of fluid is critical.

Advantages of Globe Valves

Globe valves offer superior throttling capabilities compared to stop valves, enabling precise flow control in various industrial applications. Their design allows for better sealing and less leakage, ensuring reliable shutoff even under high pressure conditions. Globe valves also provide easier maintenance due to their straightforward construction and accessible internal parts.

Advantages of Stop Valves

Stop valves offer rapid shut-off capabilities, making them ideal for emergency situations where quick flow isolation is crucial. Their simple design ensures easy maintenance and reliable performance under varying pressure conditions. Additionally, stop valves typically provide a tighter seal compared to globe valves, reducing the risk of leakage in pipeline systems.

Choosing Between Globe Valve and Stop Valve

Choosing between a globe valve and a stop valve depends on the application requirements for flow control and shutoff precision. Globe valves offer superior throttling capabilities and precise flow regulation due to their disc and seat design, making them ideal for systems requiring frequent adjustment. Stop valves provide a simpler, more straightforward shutoff mechanism, suitable for applications where on/off control is the priority and minimal pressure drop is desired.

Conclusion: Globe Valve vs Stop Valve

Globe valves offer precise flow regulation and are ideal for throttling applications, while stop valves excel at fully shutting off fluid flow with minimal pressure drop. The choice between globe and stop valves depends on the need for control versus isolation in a pipeline system. Selecting the appropriate valve enhances operational efficiency and ensures system reliability.

Globe valve Infographic

libterm.com

libterm.com