The double squirrel cage design enhances motor efficiency and starting torque by utilizing two rotor cages with different electrical resistances. This configuration improves performance under varying load conditions, making it ideal for applications requiring reliable and robust operation. Explore the full article to understand how this technology can benefit your specific needs.

Table of Comparison

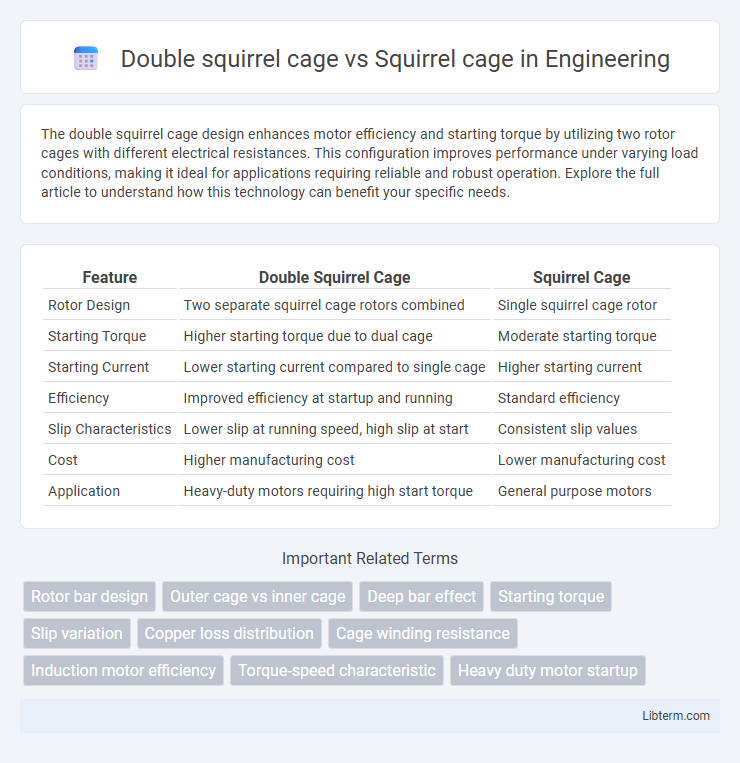

| Feature | Double Squirrel Cage | Squirrel Cage |

|---|---|---|

| Rotor Design | Two separate squirrel cage rotors combined | Single squirrel cage rotor |

| Starting Torque | Higher starting torque due to dual cage | Moderate starting torque |

| Starting Current | Lower starting current compared to single cage | Higher starting current |

| Efficiency | Improved efficiency at startup and running | Standard efficiency |

| Slip Characteristics | Lower slip at running speed, high slip at start | Consistent slip values |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Application | Heavy-duty motors requiring high start torque | General purpose motors |

Introduction to Squirrel Cage and Double Squirrel Cage Motors

Squirrel cage motors feature a rotor constructed from aluminum or copper bars short-circuited by end rings, forming a cage-like structure that provides ruggedness and reliability in industrial applications. Double squirrel cage motors enhance this design by incorporating two sets of bars, enabling separate starting and running circuits, which improve starting torque and reduce current surge during startup. The dual cage configuration distinguishes double squirrel cage motors as more efficient in handling heavy-load starts compared to standard squirrel cage motors.

Construction Differences: Squirrel Cage vs Double Squirrel Cage

The primary construction difference between a squirrel cage and a double squirrel cage lies in their rotor design: a squirrel cage rotor features a single cage made of conductive bars shorted by end rings, while a double squirrel cage rotor incorporates two cages--an outer cage with high resistance and an inner cage with low resistance--enabling improved starting torque and reduced starting current. The double squirrel cage motor's dual-cage structure allows for better control of rotor current during startup, enhancing performance in heavy-load applications. In contrast, the simpler single cage squirrel cage rotor is more cost-effective but offers relatively lower starting torque and less efficient starting characteristics.

Operating Principle Explained

The double squirrel cage motor features two rotor cages with bars of different resistances and reactances to optimize starting torque and efficiency, whereas the standard squirrel cage motor has a single rotor cage with uniform bars. During startup, the outer cage of the double squirrel cage motor provides high resistance facilitating high starting torque, while the inner cage reduces rotor resistance at running speed for improved efficiency. This dual-cage design enhances performance across various load conditions compared to the conventional squirrel cage motor.

Starting Torque Comparison

Double squirrel cage motors provide higher starting torque compared to standard squirrel cage motors due to their unique rotor design, which features two winding cages with different resistances. This construction allows for improved torque at startup, especially under heavy load conditions, making double squirrel cage motors ideal for applications requiring strong initial torque. Standard squirrel cage motors typically exhibit lower starting torque, as their single cage rotor has fixed resistance that limits torque generation during startup.

Efficiency and Performance

Double squirrel cage rotors enhance efficiency by reducing rotor losses and improving torque characteristics compared to standard squirrel cage designs. These rotors provide higher starting torque and smoother operation, leading to better overall performance in industrial motor applications. Optimized rotor geometry and dual-layer conductor bars minimize energy dissipation and maintain consistent speed, maximizing motor efficiency.

Applications in Industry

Double squirrel cage induction motors offer enhanced starting torque and better efficiency compared to single squirrel cage motors, making them ideal for heavy-duty industrial applications such as crushers, conveyors, and hoists. Single squirrel cage motors are commonly utilized in general industrial machinery requiring moderate starting torque and consistent operation, such as pumps, fans, and compressors. The choice between double and single squirrel cage motors depends on specific load characteristics and starting requirements, with double squirrel cages preferred in industries demanding high starting torque and robust performance.

Cost and Maintenance Considerations

Double squirrel cage motors typically have higher initial costs due to their more complex construction compared to standard squirrel cage motors. Maintenance expenses for double squirrel cage motors can be lower in the long term because their design reduces rotor heating and mechanical wear, enhancing durability. Standard squirrel cage motors, while cheaper upfront, may incur higher maintenance costs over time due to increased susceptibility to rotor issues and limited efficiency in variable load conditions.

Disadvantages of Each Motor Type

Squirrel cage motors commonly face challenges such as lower starting torque and difficulty in speed control, limiting their application in variable load conditions. Double squirrel cage motors, while offering improved starting torque, tend to be more complex and expensive due to their dual winding design. Both types may suffer from thermal issues under heavy loads, but the double squirrel cage motor's intricate structure can lead to increased maintenance requirements.

Selection Criteria for Motor Types

Double squirrel cage motors offer higher starting torque and better efficiency compared to standard squirrel cage motors, making them ideal for heavy-duty applications requiring frequent starts and stops. Selection criteria prioritize load characteristics, such as torque demand and starting current limitations, with double squirrel cage motors favored in industries like compressors and crushers. Cost considerations, maintenance requirements, and operational speed also influence the choice between double squirrel cage and standard squirrel cage motor types.

Summary: Which Motor to Choose?

Double squirrel cage motors offer enhanced starting torque and improved efficiency compared to single squirrel cage motors, making them ideal for applications requiring heavy starting loads or frequent starts. Single squirrel cage motors are simpler, more cost-effective, and suitable for standard industrial applications with moderate starting torque demands. Choosing between the two depends on specific load requirements, starting conditions, and budget constraints, with double squirrel cage motors preferred for demanding, high-torque environments.

Double squirrel cage Infographic

libterm.com

libterm.com