Failure Mode and Effects Analysis (FMEA) systematically identifies potential failure points within a process or product to assess their impact on performance and safety. By prioritizing risks based on severity, occurrence, and detectability, FMEA helps implement effective corrective actions that enhance reliability and prevent costly failures. Explore the rest of the article to discover practical steps for conducting FMEA and improving Your operational efficiency.

Table of Comparison

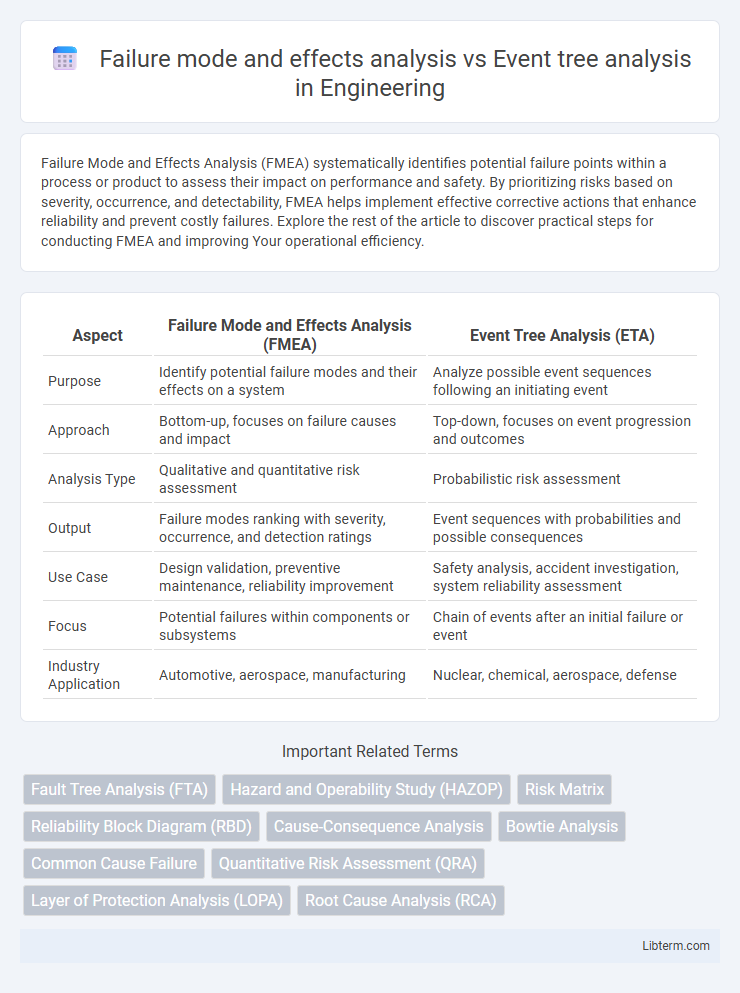

| Aspect | Failure Mode and Effects Analysis (FMEA) | Event Tree Analysis (ETA) |

|---|---|---|

| Purpose | Identify potential failure modes and their effects on a system | Analyze possible event sequences following an initiating event |

| Approach | Bottom-up, focuses on failure causes and impact | Top-down, focuses on event progression and outcomes |

| Analysis Type | Qualitative and quantitative risk assessment | Probabilistic risk assessment |

| Output | Failure modes ranking with severity, occurrence, and detection ratings | Event sequences with probabilities and possible consequences |

| Use Case | Design validation, preventive maintenance, reliability improvement | Safety analysis, accident investigation, system reliability assessment |

| Focus | Potential failures within components or subsystems | Chain of events after an initial failure or event |

| Industry Application | Automotive, aerospace, manufacturing | Nuclear, chemical, aerospace, defense |

Introduction to Risk Assessment Techniques

Failure Mode and Effects Analysis (FMEA) systematically identifies potential failure points within a system and evaluates their impacts to prioritize mitigation efforts. Event Tree Analysis (ETA) models the sequential progression of events following an initiating incident, quantifying the probabilities of various outcomes to assess risk pathways. Both techniques are essential in risk assessment, offering complementary perspectives: FMEA focuses on preventive measures by analyzing component-level failures, while ETA provides insight into event consequences and recovery strategies.

What is Failure Mode and Effects Analysis (FMEA)?

Failure Mode and Effects Analysis (FMEA) is a systematic, proactive method used to identify potential failure modes within a system, process, or product, and assess their effects on overall performance. It prioritizes risks by evaluating the severity, occurrence, and detectability of each failure mode, enabling teams to implement corrective actions before failures occur. FMEA emphasizes early detection and mitigation of failures, making it a vital tool in quality management and risk assessment across industries such as manufacturing, healthcare, and aerospace.

What is Event Tree Analysis (ETA)?

Event Tree Analysis (ETA) is a systematic, forward-looking risk assessment method used to evaluate possible outcomes following an initiating event by mapping sequences of success and failure paths through a tree-like model. It quantifies the probabilities of different end states, helping identify critical system failures and their consequences. ETA is widely applied in reliability engineering, safety analysis, and risk management to complement Failure Mode and Effects Analysis (FMEA) by focusing on event sequences rather than component failures.

Key Objectives: FMEA vs ETA

Failure Mode and Effects Analysis (FMEA) primarily aims to identify potential failure modes within a system and assess their impact on system performance to prioritize mitigation efforts. Event Tree Analysis (ETA) focuses on systematically exploring possible event sequences following an initiating event to evaluate the probability and consequences of different outcomes. FMEA helps prevent failures by proactively addressing weaknesses, while ETA aids in understanding risk pathways and decision points after an incident occurs.

Methodology Comparison: FMEA and ETA

Failure Mode and Effects Analysis (FMEA) systematically identifies potential failure modes within a system and evaluates their impacts to prioritize mitigation actions based on severity, occurrence, and detection rankings. Event Tree Analysis (ETA) employs a forward, inductive process modeling method that maps sequences of events following an initiating event, assessing the probability of various outcomes through logical branching structures. While FMEA emphasizes failure cause identification and risk prioritization through qualitative scoring, ETA focuses on quantifying event sequences and failure probabilities to evaluate system reliability and safety margins.

Strengths of Failure Mode and Effects Analysis

Failure Mode and Effects Analysis (FMEA) excels in its systematic identification and prioritization of potential failure modes based on severity, occurrence, and detectability, offering detailed insight into risk mitigation at an early design stage. Its structured approach enables cross-functional teams to pinpoint failure causes and effects, fostering proactive improvements in product reliability and safety. FMEA's strengths also include its ability to integrate easily with quality management systems and facilitate continuous improvement through iterative reviews.

Advantages of Event Tree Analysis

Event Tree Analysis (ETA) provides a dynamic, forward-looking approach that visually maps out possible outcomes following an initiating event, enhancing the understanding of complex failure sequences and their probabilities. It excels in quantifying conditional probabilities of cascading events, supporting robust risk assessment in safety-critical systems. ETA's structured scenario analysis facilitates effective decision-making by identifying critical paths and mitigation strategies with greater clarity compared to Failure Mode and Effects Analysis (FMEA).

Limitations of FMEA and ETA

Failure Mode and Effects Analysis (FMEA) often struggles with identifying complex interactions between failure modes due to its primarily qualitative nature and reliance on expert judgment, potentially overlooking rare but high-impact events. Event Tree Analysis (ETA) faces challenges in modeling highly dynamic systems because it assumes a fixed sequence of events and may not capture feedback loops or dependencies accurately. Both methodologies can suffer from incomplete data, but FMEA's limitation lies in its difficulty quantifying risk probabilities, whereas ETA can become computationally intensive and unwieldy with large event sets.

When to Use FMEA vs ETA

Failure Mode and Effects Analysis (FMEA) is best used during the design and development phases to systematically identify and prioritize potential failure modes within a system, helping teams mitigate risks early. Event Tree Analysis (ETA) is more effective in analyzing the probability of different outcomes following an initiating event, making it ideal for safety and reliability assessments after a failure occurs. Choosing FMEA facilitates proactive failure prevention, whereas ETA supports reactive analysis of event sequences and consequence evaluation.

Conclusion: Choosing the Right Risk Assessment Tool

Choosing between Failure Mode and Effects Analysis (FMEA) and Event Tree Analysis (ETA) depends on the specific risk assessment goals and system complexity. FMEA excels in identifying potential failure modes and prioritizing corrective actions at the component level, making it ideal for design and manufacturing phases. ETA provides a comprehensive evaluation of event sequences and their consequences, best suited for analyzing complex system behaviors and emergency response scenarios.

Failure mode and effects analysis Infographic

libterm.com

libterm.com