Sequential Function Chart (SFC) is a powerful graphical programming language used to design and visualize control sequences in automated systems, ensuring clear communication of each step's function. It enhances your ability to manage complex processes by breaking them into smaller, manageable steps with defined transitions and actions. Discover how SFC can optimize your control system by reading the rest of the article.

Table of Comparison

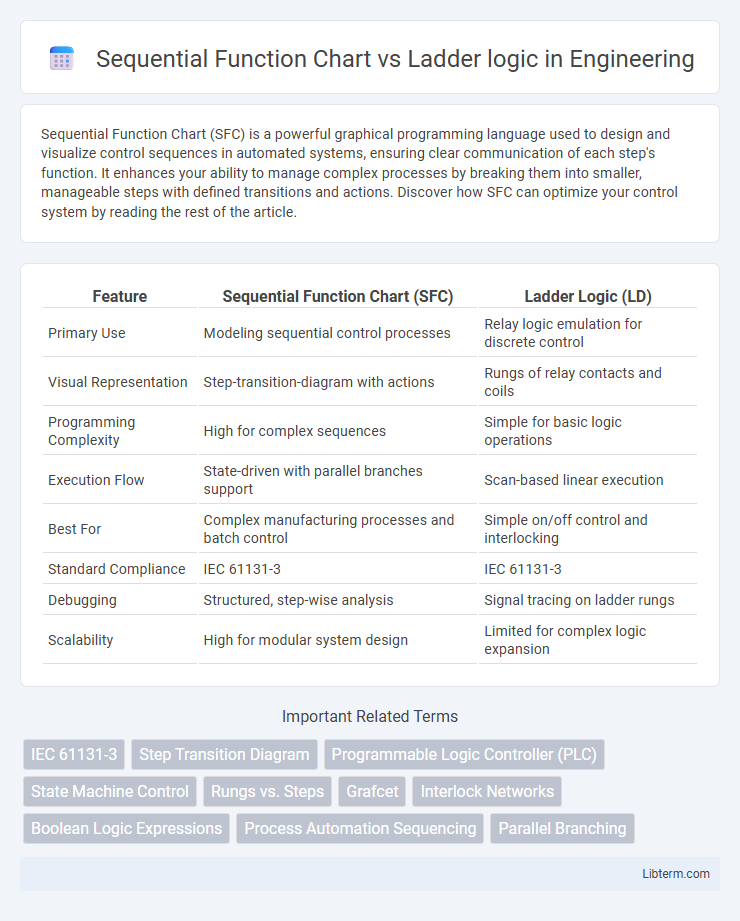

| Feature | Sequential Function Chart (SFC) | Ladder Logic (LD) |

|---|---|---|

| Primary Use | Modeling sequential control processes | Relay logic emulation for discrete control |

| Visual Representation | Step-transition-diagram with actions | Rungs of relay contacts and coils |

| Programming Complexity | High for complex sequences | Simple for basic logic operations |

| Execution Flow | State-driven with parallel branches support | Scan-based linear execution |

| Best For | Complex manufacturing processes and batch control | Simple on/off control and interlocking |

| Standard Compliance | IEC 61131-3 | IEC 61131-3 |

| Debugging | Structured, step-wise analysis | Signal tracing on ladder rungs |

| Scalability | High for modular system design | Limited for complex logic expansion |

Introduction to Sequential Function Chart and Ladder Logic

Sequential Function Chart (SFC) is a graphical programming language standardized by IEC 61131-3 used for designing complex control systems through step-by-step sequences and transitions. Ladder Logic, also standardized by IEC 61131-3, represents programs using relay logic diagrams, making it intuitive for electricians familiar with electrical schematics. Both SFC and Ladder Logic facilitate programmable logic controller (PLC) programming but differ in structure: SFC emphasizes sequential flow with clear state transitions, while Ladder Logic mimics electrical relay circuits for logical control.

Core Concepts of Sequential Function Chart (SFC)

Sequential Function Chart (SFC) core concepts center on structuring control processes into steps, transitions, and actions to provide clear, visual representations of sequence flow in automation tasks. Steps represent distinct states or operations, transitions define the logical conditions for moving between steps, and actions are executed when steps are active, enabling modular and systematic control design. SFC enhances readability and modularity compared to Ladder logic by emphasizing sequence control through state-based diagrams rather than relay logic depictions.

Core Concepts of Ladder Logic (LD)

Ladder Logic (LD) is a graphical programming language resembling electrical relay logic, where logic is represented using rungs on a ladder diagram for easy visualization of control circuits. Core concepts of Ladder Logic include contacts (normally open and closed) that act as input conditions and coils that represent outputs, facilitating real-time decision making in programmable logic controllers (PLCs). Unlike Sequential Function Chart (SFC), which emphasizes state transitions and actions, Ladder Logic prioritizes relay-based control flow and continuous scanning for rapid response in industrial automation.

Visual Representation and Structure Comparison

Sequential Function Chart (SFC) uses a graphical flowchart-like representation, displaying steps, transitions, and actions in a clear, hierarchical manner, which enhances readability and systematic process flow visualization. Ladder Logic (LD) resembles electrical relay schematics with rungs representing control logic, providing an intuitive interface for users familiar with relay control and making it well-suited for simple repeated processes. SFC's structured and modular design supports complex process sequences and parallelism, while Ladder Logic's linear and straightforward layout excels in discrete control and troubleshooting.

Programming Methodology: SFC vs Ladder Logic

Sequential Function Chart (SFC) programming methodology emphasizes a visual representation of control sequences using steps, transitions, and actions, enabling clear depiction of process flows and parallel operations. Ladder Logic relies on graphical symbols resembling electrical relay logic, using rungs to represent control circuits primarily suited for discrete control and simple decision-making. SFC is advantageous for complex, sequential, and batch processes with modular programming, while Ladder Logic excels in straightforward, event-driven tasks with fast execution and ease of debugging.

Ease of Troubleshooting and Maintenance

Sequential Function Chart (SFC) offers a clear visual representation of process sequences, making it easier to identify faults in complex control systems compared to Ladder Logic, which can become cluttered in extensive applications. SFC's modular approach simplifies troubleshooting by isolating individual steps and transitions, facilitating quicker diagnosis and corrections. Ladder Logic, while widely used, often requires more experience to interpret complex rung interactions, potentially increasing maintenance time.

Application Areas and Industrial Use Cases

Sequential Function Chart (SFC) excels in complex process control where step-by-step sequence execution and clear visualization of state transitions are critical, commonly used in batch processing, chemical industries, and automated manufacturing lines. Ladder Logic is widely adopted in discrete control systems, such as assembly lines, packaging machines, and robotic arms, due to its simplicity and direct mapping to relay logic, making it ideal for real-time control and troubleshooting. Industrial automation frequently implements SFC for processes requiring modular and hierarchical control structures, while Ladder Logic remains dominant in scenarios demanding fast response and straightforward implementation on programmable logic controllers (PLCs).

Flexibility and Scalability in Control Systems

Sequential Function Chart (SFC) offers superior flexibility in control systems by allowing clear visualization of complex sequences with easily modifiable states and transitions, supporting hierarchical and parallel processes. Ladder Logic, while intuitive and widely used for simple relay-based control, presents limitations in scalability due to its linear and less modular structure, making complex system expansions more challenging. SFC's modular design enhances scalability by enabling incremental development and integration of additional control steps without extensive rewiring or code rewriting, ideal for evolving automation requirements.

Performance, Efficiency, and Execution Speed

Sequential Function Chart (SFC) offers superior clarity for complex process control with high modularity, improving troubleshooting and maintainability. Ladder Logic (LD) is widely used for simple discrete control tasks, providing faster execution speed due to its straightforward row-by-row scan approach. In terms of performance and efficiency, SFC excels in managing parallel processes and sequence control, while Ladder Logic typically delivers quicker cycle times in simpler automation environments.

Selecting the Right Approach: Factors to Consider

When selecting between Sequential Function Chart (SFC) and Ladder Logic for industrial automation, consider the complexity and clarity of the process; SFC excels in visualizing sequential steps and parallel branches, making it ideal for complex, state-driven processes. Ladder Logic suits simpler, relay-based control systems where ease of troubleshooting and familiarity to electricians are priorities. Evaluate factors such as process complexity, scalability, debugging needs, and team expertise to determine the most effective programming approach.

Sequential Function Chart Infographic

libterm.com

libterm.com