Turning is a versatile machining process used to create precise cylindrical parts by removing material from a rotating workpiece with a cutting tool. It plays a crucial role in manufacturing industries, enabling the production of components with tight tolerances and smooth surface finishes. Discover how mastering turning techniques can enhance your machining skills in the rest of this article.

Table of Comparison

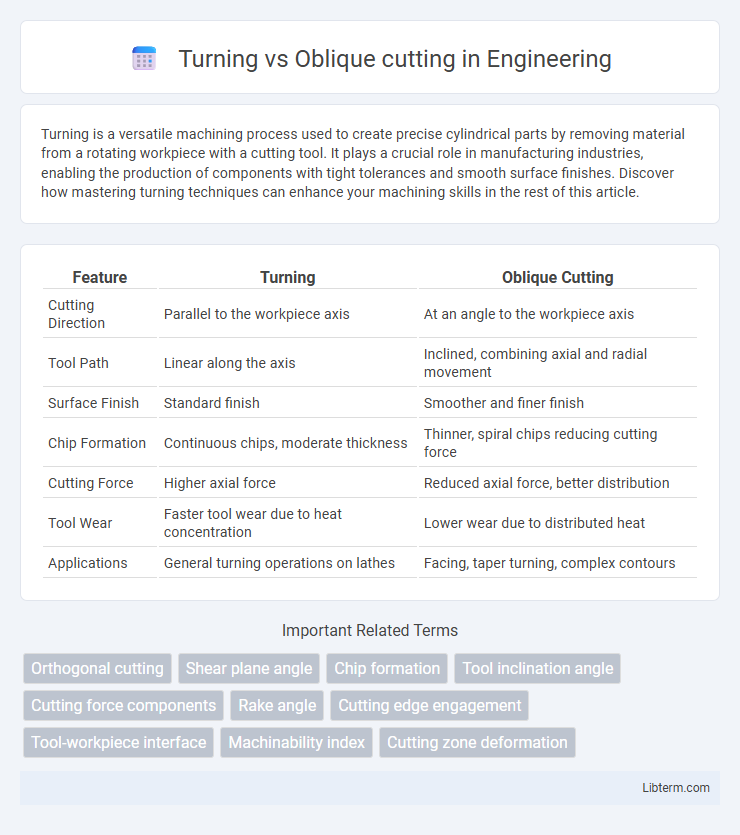

| Feature | Turning | Oblique Cutting |

|---|---|---|

| Cutting Direction | Parallel to the workpiece axis | At an angle to the workpiece axis |

| Tool Path | Linear along the axis | Inclined, combining axial and radial movement |

| Surface Finish | Standard finish | Smoother and finer finish |

| Chip Formation | Continuous chips, moderate thickness | Thinner, spiral chips reducing cutting force |

| Cutting Force | Higher axial force | Reduced axial force, better distribution |

| Tool Wear | Faster tool wear due to heat concentration | Lower wear due to distributed heat |

| Applications | General turning operations on lathes | Facing, taper turning, complex contours |

Introduction to Turning and Oblique Cutting

Turning involves rotating a workpiece on a lathe while a single-point cutting tool removes material to create cylindrical shapes, optimizing precision and surface finish. Oblique cutting occurs when the cutting edge meets the workpiece at an angle, enhancing chip flow and reducing cutting forces. Both processes are fundamental in machining for shaping metals with specific tool geometries and cutting conditions to achieve desired dimensions and surface quality.

Definition of Turning

Turning is a machining process where a cutting tool removes material from the external surface of a rotating workpiece to create cylindrical shapes. Oblique cutting differs by using a cutting edge angled to the direction of workpiece rotation, generating a helical chip flow. Understanding turning's definition is essential for distinguishing it from oblique cutting techniques in metalworking.

Understanding Oblique Cutting

Oblique cutting involves a cutting edge inclined at an angle to the direction of tool travel, resulting in a shearing action that reduces cutting forces and improves surface finish compared to turning. This method allows chips to flow away more smoothly, minimizing heat generation and tool wear while enhancing machining efficiency. Understanding oblique cutting is crucial for optimizing tool geometry and parameters in operations requiring precision and extended tool life.

Key Differences Between Turning and Oblique Cutting

Turning involves the cutting tool moving parallel to the workpiece axis, creating a cylindrical shape, while oblique cutting uses a tool set at an angle to the workpiece, producing a helical chip flow. The primary difference lies in the chip formation and cutting force direction; turning generates axial force with straight chip flow, whereas oblique cutting generates a combination of axial and radial forces with a spiral chip. Tool geometry varies, with turning tools having a simpler edge geometry and oblique cutters featuring angled cutting edges to facilitate smoother cutting and reduced tool wear.

Tool Geometry in Turning vs Oblique Cutting

Turning tool geometry typically features a single-point cutting edge with a rake angle optimized for axial cutting, enabling precise cylindrical shapes. In contrast, oblique cutting tools have an angled cutting edge relative to the workpiece axis, resulting in a shearing action that reduces cutting forces and improves surface finish. The main geometric difference lies in the orientation of the cutting edge: turning tools align parallel to the axis, while oblique tools are set at an angle, influencing chip flow and tool wear patterns.

Material Removal Mechanisms

Turning involves removing material by advancing a single-point cutting tool along the rotating workpiece, generating continuous chips through shearing action that occurs primarily at the tool-workpiece interface. Oblique cutting features a cutting edge inclined at an angle to the workpiece surface, resulting in a more complex material removal mechanism combining shearing, sliding, and rubbing, which affects chip flow and cutting forces. The difference in chip formation and stress distribution between turning and oblique cutting influences surface finish, tool wear, and machining efficiency.

Surface Finish Comparison

Turning typically produces a smoother surface finish due to the controlled cutting path and consistent tool engagement, resulting in finer surface roughness values. Oblique cutting often generates a rougher surface finish because the cutting edge interacts with the material at an angle, causing increased tool vibration and irregular chip formation. Surface finish quality in turning benefits from optimized feed rate and cutting speed, whereas oblique cutting requires precise tool geometry adjustments to minimize surface imperfections.

Applications in Manufacturing

Turning is primarily used for producing cylindrical parts such as shafts, pins, and bushings due to its ability to create precise diameters and smooth finishes. Oblique cutting is commonly applied in milling processes to efficiently remove material from complex angled surfaces, improving productivity in components like gears and turbine blades. Both techniques are essential in manufacturing for shaping metals, with turning suited for rotational symmetry and oblique cutting favored in contouring and angled surface creation.

Advantages and Limitations

Turning offers high precision and excellent surface finish for cylindrical parts, making it ideal for producing shafts and threads with tight tolerances. Its limitation lies in reduced effectiveness on complex geometries and internal features, where access is constrained. Oblique cutting enhances tool life and chip removal efficiency by distributing cutting forces over a larger area, but it may introduce dimensional inaccuracies and increased tool wear in materials with variable hardness.

Summary and Future Trends

Turning processes involve machining a rotating workpiece with a fixed cutting tool to produce cylindrical parts, ensuring precision and efficient material removal. Oblique cutting uses angled cutting edges for improved chip flow and reduced cutting forces, enhancing surface finish and tool life. Future trends emphasize integration of AI for adaptive control, advanced coatings for tool durability, and hybrid methods combining turning and oblique cutting to optimize performance and sustainability.

Turning Infographic

libterm.com

libterm.com