A buck converter efficiently steps down voltage from a higher level to a lower one while maintaining high power efficiency, making it ideal for power supply applications. It operates by rapidly switching on and off, controlling the energy transferred to the load, which reduces heat dissipation compared to linear regulators. Discover how a buck converter can optimize your power management by reading the complete article.

Table of Comparison

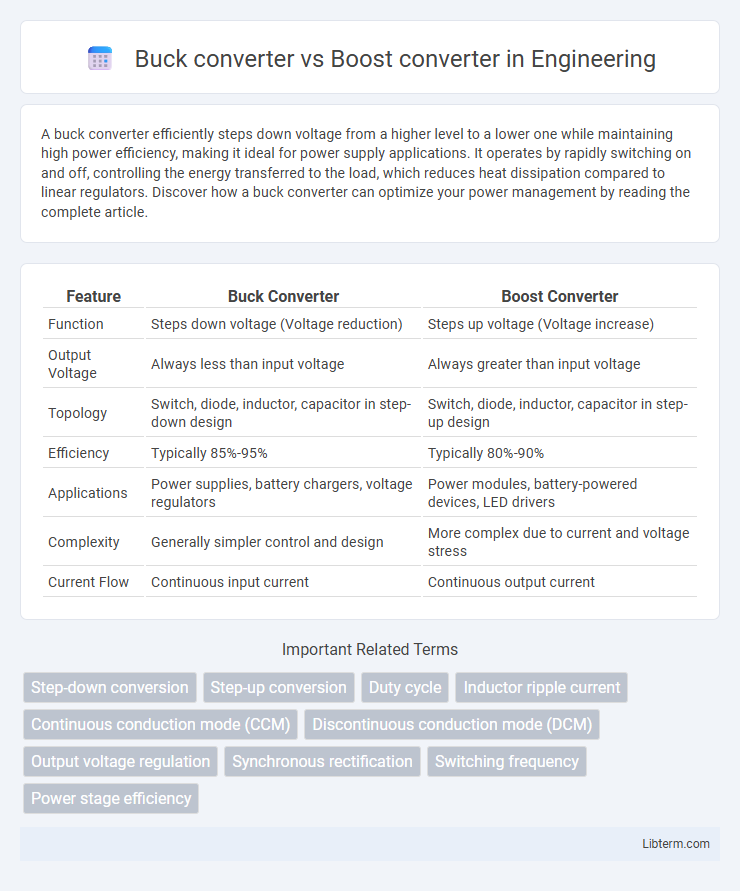

| Feature | Buck Converter | Boost Converter |

|---|---|---|

| Function | Steps down voltage (Voltage reduction) | Steps up voltage (Voltage increase) |

| Output Voltage | Always less than input voltage | Always greater than input voltage |

| Topology | Switch, diode, inductor, capacitor in step-down design | Switch, diode, inductor, capacitor in step-up design |

| Efficiency | Typically 85%-95% | Typically 80%-90% |

| Applications | Power supplies, battery chargers, voltage regulators | Power modules, battery-powered devices, LED drivers |

| Complexity | Generally simpler control and design | More complex due to current and voltage stress |

| Current Flow | Continuous input current | Continuous output current |

Introduction to Buck and Boost Converters

Buck converters step down voltage from a higher input to a lower output level, optimizing power efficiency for applications like battery-powered devices. Boost converters increase voltage from a lower input to a higher output, crucial for systems requiring voltage elevation such as LED drivers and power amplifiers. Both converters utilize switching elements and energy storage components like inductors to regulate voltage with minimal power loss.

Basic Operating Principles

A Buck converter operates by switching its transistor on and off, controlling energy stored in an inductor to step down voltage efficiently while maintaining continuous current flow. In contrast, a Boost converter stores energy in the inductor when the transistor is on and releases it to the output through a diode when off, thereby stepping up the input voltage. Both converters use pulse-width modulation (PWM) to regulate output voltage, but the Buck converter reduces voltage while the Boost converter increases it.

Key Differences in Circuit Design

Buck converters feature a step-down voltage design using a high-side switch and inductor to reduce input voltage efficiently. Boost converters employ a step-up topology with an inductor and a diode to increase input voltage to a higher output level. The primary difference lies in the switch placement and energy storage components, affecting voltage conversion direction and component ratings.

Efficiency Comparison

Buck converters typically offer higher efficiency when stepping down voltage due to lower conduction losses and simpler design. Boost converters, while efficient for voltage step-up, often experience increased power loss from higher current stresses and switching losses. Efficiency in both converters heavily depends on components, load conditions, and switching frequencies.

Voltage Conversion Capabilities

Buck converters efficiently step down input voltage to a lower output voltage with high efficiency, making them ideal for applications requiring stable reduced voltage levels. Boost converters increase input voltage to a higher output voltage, enabling devices to operate above the supply voltage limit. The choice between buck and boost converters depends on whether the application demands voltage reduction or elevation within power supply constraints.

Typical Applications

Buck converters are commonly used in applications requiring voltage step-down, such as powering low-voltage microcontrollers, battery charging circuits, and regulating voltage in laptops and LED drivers. Boost converters are typically applied in scenarios needing voltage step-up, including powering high-voltage LEDs, battery-powered devices requiring higher output voltage, and DC-DC voltage conversion for renewable energy systems. Both converters are essential in power management systems for optimizing energy efficiency and maintaining stable output voltage under varying load conditions.

Advantages of Buck Converters

Buck converters offer high efficiency for voltage step-down applications by minimizing power loss through rapid switching and energy storage components. Their compact design and lower output voltage ripple make them ideal for power-sensitive devices and battery-powered systems. Compared to boost converters, buck converters provide better thermal performance and stable output voltage under varying load conditions.

Advantages of Boost Converters

Boost converters provide the advantage of stepping up input voltage to higher output levels, making them ideal for applications requiring voltage amplification from lower supply voltages, such as battery-powered devices. They offer high efficiency and compact size due to fewer components and continuous current flow through the inductor, minimizing energy loss and improving performance in portable electronics. Boost converters also support wide input voltage ranges and fast transient response, enhancing their suitability for power management in renewable energy systems and LED drivers.

Design Considerations and Challenges

Buck converters require careful attention to inductor selection and switching frequency to minimize output voltage ripple and improve efficiency in step-down voltage regulation. Boost converters face challenges managing voltage stress on components, particularly the switch and diode, due to the higher output voltage compared to input, necessitating robust design for reliability. Thermal management and loop compensation are critical in both converter types to ensure stable operation and prevent overheating under varying load conditions.

Choosing the Right Converter for Your Needs

Selecting between a Buck converter and a Boost converter depends on whether your application requires voltage step-down or step-up regulation. Buck converters efficiently reduce higher input voltages to lower output levels, ideal for powering low-voltage devices from a higher voltage source. Boost converters increase lower voltages to higher output levels, suitable for applications needing voltage elevation without sacrificing efficiency, such as battery-powered systems requiring stable, higher voltages.

Buck converter Infographic

libterm.com

libterm.com