Proper climbing form enhances efficiency and reduces injury risk by promoting balanced body positioning, controlled movements, and strategic foot placement. Engaging your core and maintaining three points of contact with the wall helps optimize stability and power transfer. Explore the article to learn key techniques that will improve your climbing performance and confidence.

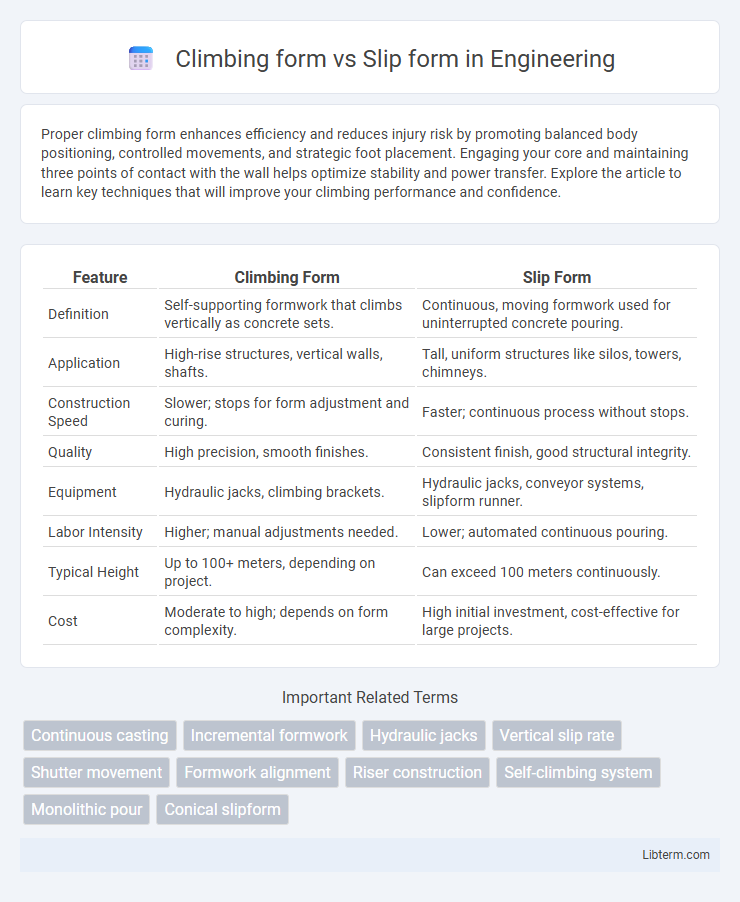

Table of Comparison

| Feature | Climbing Form | Slip Form |

|---|---|---|

| Definition | Self-supporting formwork that climbs vertically as concrete sets. | Continuous, moving formwork used for uninterrupted concrete pouring. |

| Application | High-rise structures, vertical walls, shafts. | Tall, uniform structures like silos, towers, chimneys. |

| Construction Speed | Slower; stops for form adjustment and curing. | Faster; continuous process without stops. |

| Quality | High precision, smooth finishes. | Consistent finish, good structural integrity. |

| Equipment | Hydraulic jacks, climbing brackets. | Hydraulic jacks, conveyor systems, slipform runner. |

| Labor Intensity | Higher; manual adjustments needed. | Lower; automated continuous pouring. |

| Typical Height | Up to 100+ meters, depending on project. | Can exceed 100 meters continuously. |

| Cost | Moderate to high; depends on form complexity. | High initial investment, cost-effective for large projects. |

Introduction to Climbing Form and Slip Form

Climbing form is a reusable, self-climbing concrete formwork system widely used for tall structures like core walls, enabling continuous vertical casting without disassembly. Slip form, in contrast, involves a continuously moving formwork that ascends slowly, allowing for seamless, uninterrupted concrete pouring in structures such as silos and towers. Both methods optimize construction speed and structural integrity through efficient formwork technology tailored to specific project requirements.

Overview of Concrete Formwork Systems

Climbing form and slip form are two primary concrete formwork systems used for vertical structures, each optimizing different construction needs. Climbing form systems are reusable, mechanically lifted formworks ideal for high-rise cores and shafts, providing precise shaping and smooth finishes by moving in increments. Slip form involves a continuous, steady upward movement of the formwork, enabling rapid construction of tall, uniform concrete structures like silos and towers with minimal joints.

What is Climbing Form?

Climbing form is a construction method used for casting concrete structures like high-rise buildings and bridges, where the formwork progressively moves upward as each section is poured and cured, enabling continuous vertical construction. This self-climbing system is typically attached to the structure itself and operated using hydraulic jacks, reducing the need for scaffolding and enhancing site safety and efficiency. It contrasts with slip form, which involves a continuously moving formwork that moves at a steady pace without stops, ideal for tall, uniform structures such as silos and towers.

What is Slip Form?

Slip form is a continuous concrete pouring technique used in constructing tall structures such as silos, towers, and chimneys. It involves moving the formwork slowly upward as the concrete sets, allowing for a seamless, joint-free finish. This method contrasts with climbing form, which progresses in discrete stages with scheduled stops for form repositioning.

Key Differences Between Climbing Form and Slip Form

Climbing form and slip form differ primarily in their construction methods and applications. Climbing form is a reusable, movable formwork system that climbs vertically with the structure, ideal for high-rise buildings and cores, ensuring precise shaping and surface finish. Slip form continuously moves upward as concrete is poured, best suited for tall, uniform structures like silos or towers, enabling faster construction but with less detailed surface control.

Advantages of Climbing Formwork

Climbing formwork offers significant advantages such as enhanced construction speed by enabling continuous vertical concrete pouring without disassembly, which reduces project timelines. It improves safety by providing stable working platforms that adjust as the structure rises, minimizing the risk of falls and accidents. The system's reusability and adaptability for complex geometries also lower labor costs and material waste, optimizing overall efficiency in high-rise and infrastructure projects.

Benefits of Slip Form Construction

Slip form construction offers continuous, speedy progress by using a moving form that allows concrete to be poured and set simultaneously, significantly reducing construction time compared to climbing form methods. This technique enhances structural integrity through uniform concrete curing and reduces labor costs due to automation and fewer form adjustments. Slip form is particularly beneficial for tall, vertical structures like silos, towers, and high-rise cores, where seamless, monolithic walls improve durability and resistance to environmental stresses.

Applications and Use Cases

Climbing form is ideal for constructing tall vertical structures such as high-rise buildings, bridges, and silos due to its ability to move upward with the structure, enabling continuous concrete pouring and minimizing construction joints. Slip form excels in applications requiring rapid, continuous vertical concrete placement like silos, chimneys, and towers, as the formwork moves steadily upwards at a controlled pace. Both methods optimize efficiency and structural integrity but are chosen based on project scale, speed requirements, and design complexity.

Choosing the Right Formwork System

Choosing the right formwork system between climbing form and slip form depends on project height, construction speed, and structural complexity. Climbing formwork is ideal for vertical structures with complex shapes, offering flexibility and reusability, while slip form is suited for continuous, high-speed pours in uniform sections like silos and towers. Evaluating labor skills, cycle time, and material costs ensures optimal selection for efficient and safe concrete construction.

Conclusion: Climbing Form vs Slip Form

Climbing form systems offer precise, reusable molds ideal for high-rise construction, providing efficiency in vertical progression with enhanced safety features. Slip form techniques enable continuous, seamless concrete pouring, best suited for tall, uniform structures like silos and towers, optimizing speed and structural integrity. The choice depends on project specifics: climbing forms excel in segmented, complex projects, while slip forms favor uniform, accelerated builds.

Climbing form Infographic

libterm.com

libterm.com