Hot rolling is a metalworking process where metals are heated above their recrystallization temperature and passed through rollers to achieve desired shapes and thicknesses. This method enhances the material's ductility, making it easier to form complex designs while improving surface finish and mechanical properties. Explore this article to understand how hot rolling can optimize your manufacturing workflow and product quality.

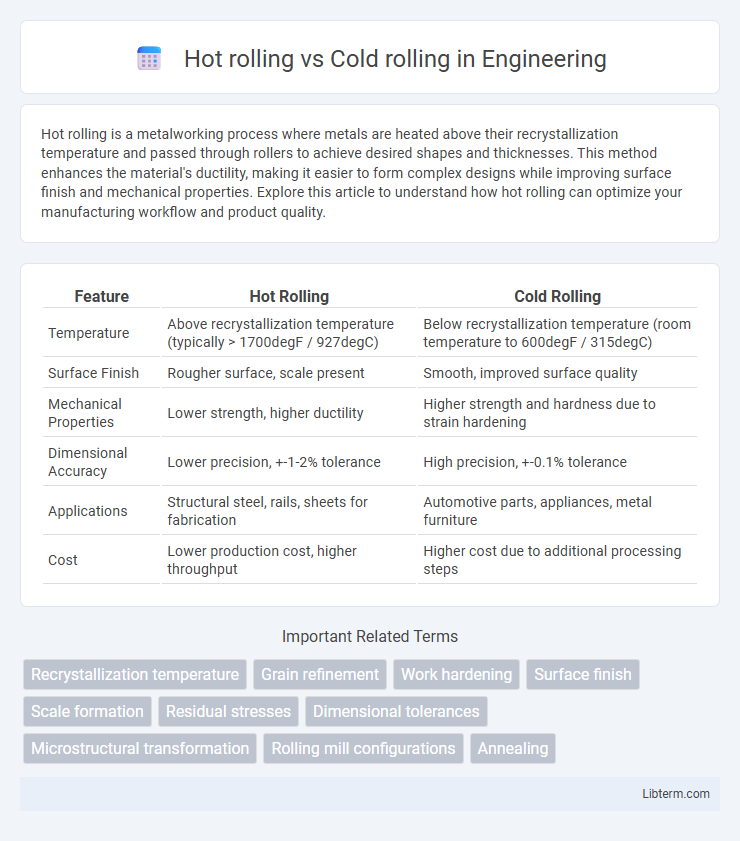

Table of Comparison

| Feature | Hot Rolling | Cold Rolling |

|---|---|---|

| Temperature | Above recrystallization temperature (typically > 1700degF / 927degC) | Below recrystallization temperature (room temperature to 600degF / 315degC) |

| Surface Finish | Rougher surface, scale present | Smooth, improved surface quality |

| Mechanical Properties | Lower strength, higher ductility | Higher strength and hardness due to strain hardening |

| Dimensional Accuracy | Lower precision, +-1-2% tolerance | High precision, +-0.1% tolerance |

| Applications | Structural steel, rails, sheets for fabrication | Automotive parts, appliances, metal furniture |

| Cost | Lower production cost, higher throughput | Higher cost due to additional processing steps |

Introduction to Metal Rolling Processes

Metal rolling processes involve shaping metal by passing it between rollers to reduce thickness and improve mechanical properties. Hot rolling occurs above the metal's recrystallization temperature, enhancing ductility and allowing larger deformations, while cold rolling happens below this temperature, producing smoother surfaces and tighter dimensional tolerances. Both methods are essential in manufacturing industries to achieve desired metal characteristics and precise geometries.

What is Hot Rolling?

Hot rolling is a metalworking process where steel or other metals are heated above their recrystallization temperature, typically above 1,200degF (650degC), to facilitate easy shaping and deformation. This method refines grain structures, improves ductility, and allows for producing large, rough shapes such as sheets, plates, and bars. Hot rolling is ideal for reducing thickness and altering the metal's cross-section while enhancing mechanical properties through controlled heating and deformation.

What is Cold Rolling?

Cold rolling is a metalworking process that involves deforming steel or other metals below their recrystallization temperature to enhance strength and surface finish. This technique improves dimensional accuracy, surface smoothness, and mechanical properties such as hardness and tensile strength. Unlike hot rolling, cold rolling produces thinner sheets with tighter tolerances, making it ideal for applications requiring precise shapes and high-quality surfaces.

Key Differences Between Hot Rolling and Cold Rolling

Hot rolling involves processing metals at temperatures above their recrystallization point, resulting in improved ductility and reduced strength, while cold rolling is performed below this temperature, increasing strength and surface finish quality. Hot rolled materials exhibit rougher surfaces and dimensional variations, whereas cold rolled products have smoother surfaces and tighter tolerances. Key differences include thermal conditions, mechanical properties, surface finish, and application suitability in industries like automotive and construction.

Advantages of Hot Rolling

Hot rolling enhances metal ductility by processing materials above their recrystallization temperature, resulting in improved workability and reduced internal stresses. This method allows for the efficient production of large, complex shapes with uniform thickness and superior surface texture. Hot rolling also eliminates scale and defects, leading to better mechanical properties and increased strength in structural steel applications.

Advantages of Cold Rolling

Cold rolling enhances metal strength and surface finish by deforming steel below its recrystallization temperature, resulting in improved dimensional accuracy and tighter tolerances compared to hot rolling. This process produces smoother surfaces with superior mechanical properties, such as increased yield strength and hardness, making it ideal for applications requiring high precision and aesthetic appeal. Cold rolled steel also exhibits better fatigue resistance and improved formability, beneficial for automotive, construction, and appliance manufacturing industries.

Applications of Hot Rolled Products

Hot rolled products are widely used in construction, automotive frames, and heavy machinery due to their enhanced ductility and ability to withstand high stress. These materials are ideal for large structural components like I-beams, railroad tracks, and shipbuilding plates because hot rolling improves toughness and formability. Their relatively lower surface finish and dimensional precision make them less suitable for applications requiring tight tolerances compared to cold rolled products.

Applications of Cold Rolled Products

Cold rolled products are widely used in automotive body panels due to their superior surface finish and dimensional accuracy. They also find applications in home appliances and electrical cabinets where enhanced strength and corrosion resistance are critical. Precision engineering components and construction materials benefit from the improved mechanical properties and tight tolerances achievable through cold rolling.

Factors to Consider in Choosing Rolling Methods

Material properties such as hardness, ductility, and thickness significantly influence the choice between hot rolling and cold rolling. Hot rolling is preferred for large deformation of metals at high temperatures, enhancing workability and reducing residual stresses, while cold rolling offers superior surface finish, dimensional accuracy, and increased strength through strain hardening. Cost efficiency, production speed, and final application requirements are critical factors in determining the optimal rolling method for specific metal processing tasks.

Conclusion: Hot Rolling vs Cold Rolling

Hot rolling is ideal for shaping large steel sections due to its ability to process metal at high temperatures, resulting in improved ductility and reduced internal stresses. Cold rolling offers superior surface finish, tighter tolerances, and enhanced mechanical properties through strain hardening, making it suitable for precision components. Choosing between hot rolling and cold rolling depends on application requirements such as dimensional accuracy, surface quality, and mechanical strength.

Hot rolling Infographic

libterm.com

libterm.com