Feedforward control predicts disturbances and compensates for them before they affect the system, improving overall stability and performance. Unlike feedback control, which reacts to errors after they occur, feedforward relies on modeling and measurement of inputs to adjust outputs proactively. Explore the article to understand how feedforward control can enhance your system's accuracy and efficiency.

Table of Comparison

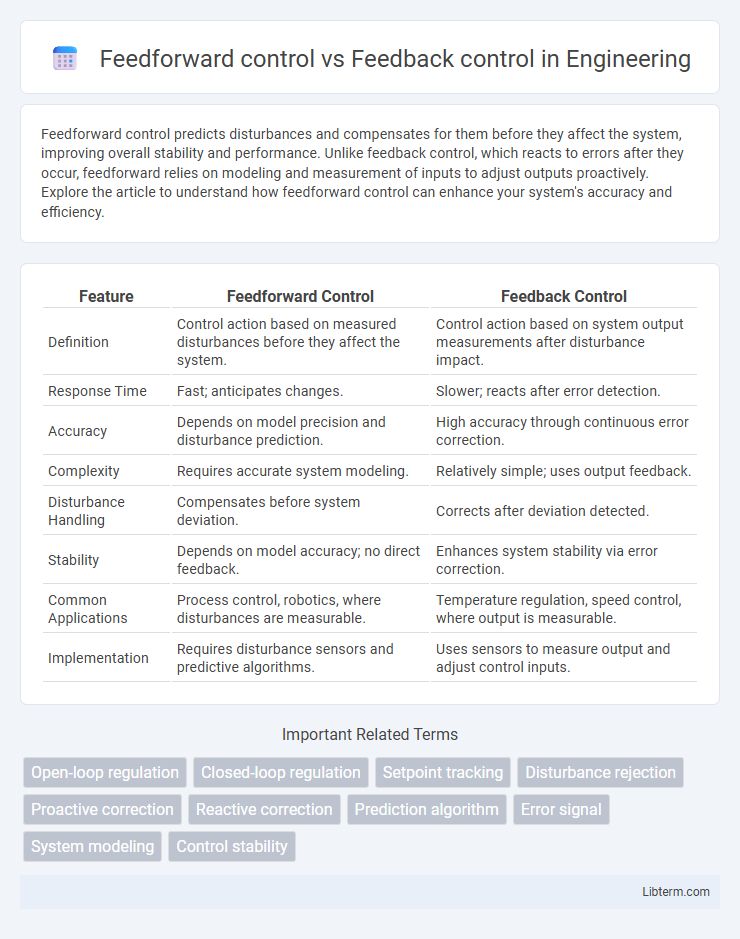

| Feature | Feedforward Control | Feedback Control |

|---|---|---|

| Definition | Control action based on measured disturbances before they affect the system. | Control action based on system output measurements after disturbance impact. |

| Response Time | Fast; anticipates changes. | Slower; reacts after error detection. |

| Accuracy | Depends on model precision and disturbance prediction. | High accuracy through continuous error correction. |

| Complexity | Requires accurate system modeling. | Relatively simple; uses output feedback. |

| Disturbance Handling | Compensates before system deviation. | Corrects after deviation detected. |

| Stability | Depends on model accuracy; no direct feedback. | Enhances system stability via error correction. |

| Common Applications | Process control, robotics, where disturbances are measurable. | Temperature regulation, speed control, where output is measurable. |

| Implementation | Requires disturbance sensors and predictive algorithms. | Uses sensors to measure output and adjust control inputs. |

Introduction to Control Systems

Feedforward control anticipates disturbances by adjusting inputs based on a model of the system, enabling proactive corrections without waiting for errors to occur. Feedback control relies on measuring the output and comparing it to the desired setpoint, making reactive adjustments to minimize the error. In control systems, combining feedforward and feedback strategies enhances stability, accuracy, and robustness in dynamic environments.

Defining Feedforward Control

Feedforward control involves anticipating system disturbances and adjusting inputs proactively to maintain desired output without waiting for errors to occur. Unlike feedback control, which reacts to deviations by correcting errors after they happen, feedforward control relies on predictive models and real-time data to prevent errors before they arise. This proactive approach enhances system stability and responsiveness in dynamic environments such as industrial automation and process control.

Defining Feedback Control

Feedback control is a regulatory mechanism that continuously monitors output performance and adjusts inputs to maintain desired system behavior, minimizing deviations caused by disturbances. It relies on real-time data from sensors to compare actual outputs with target values, enabling corrective actions to reduce error. This approach contrasts with feedforward control, which anticipates changes by adjusting inputs based on predicted disturbances without relying on output feedback.

Key Differences Between Feedforward and Feedback

Feedforward control anticipates disturbances and adjusts system inputs proactively based on predictive models, while feedback control reacts to deviations by measuring output and correcting errors after they occur. Feedforward systems require accurate models of the process and disturbance variables, whereas feedback systems rely on real-time output measurements for error correction. The primary advantage of feedforward control is its ability to prevent errors before they happen, whereas feedback control excels in maintaining stability despite model uncertainties and unforeseen changes.

Advantages of Feedforward Control

Feedforward control enhances system performance by anticipating disturbances before they affect the output, allowing for immediate corrective actions that reduce response time and improve stability. It minimizes the reliance on error correction, which leads to increased accuracy and efficiency in dynamic environments. By proactively managing inputs based on predictive models, feedforward control reduces energy consumption and wear on system components compared to feedback control.

Advantages of Feedback Control

Feedback control offers precise regulation by continuously monitoring output and adjusting inputs to minimize errors, enhancing system stability and accuracy. It compensates for disturbances and model uncertainties in real-time, ensuring consistent performance under varying conditions. This adaptive nature makes feedback control essential in applications such as temperature regulation, cruise control, and industrial process management.

Limitations of Feedforward Control

Feedforward control often struggles with accurately predicting system disturbances due to its reliance on pre-measured inputs and lacks the ability to correct errors caused by unanticipated changes. This limitation reduces its effectiveness in dynamic environments where real-time feedback is crucial for maintaining stability and performance. In contrast, feedback control continuously adjusts based on actual output, making it more robust in handling variability and uncertainty.

Limitations of Feedback Control

Feedback control relies on measuring output and adjusting inputs to correct deviations, but it faces inherent limitations such as delayed response times that reduce effectiveness in fast-changing systems. This control method can lead to oscillations or instability when disturbances occur abruptly, as it reacts only after errors are detected. Sensitivity to measurement noise and sensor inaccuracies further limits feedback control performance in precision-critical applications.

Applications in Modern Industry

Feedforward control is widely applied in chemical processing industries to anticipate disturbances and adjust processes proactively, enhancing product quality and reducing waste. Feedback control dominates in manufacturing automation, continuously monitoring outputs such as temperature, pressure, or speed to correct deviations and maintain system stability. Combining feedforward and feedback control is prevalent in robotics and automotive systems, optimizing performance by predicting changes and correcting errors in real-time.

Choosing the Right Control Strategy

Feedforward control anticipates disturbances by adjusting inputs before changes affect the system, ideal for processes with measurable, predictable variables, whereas feedback control corrects deviations after they occur, suitable for systems with unpredictable disturbances or model inaccuracies. Selecting the right control strategy depends on system dynamics, disturbance characteristics, sensor reliability, and required response time. Hybrid approaches combining feedforward and feedback control often optimize performance by leveraging proactive adjustments with corrective feedback.

Feedforward control Infographic

libterm.com

libterm.com