Fatigue crack growth rate measures how quickly a crack in a material expands under cyclic loading, directly impacting the structural integrity and lifespan of components. Understanding this rate helps engineers predict failure times and design more durable materials or maintenance schedules. Explore the rest of the article to learn how fatigue crack growth influences your engineering decisions and safety protocols.

Table of Comparison

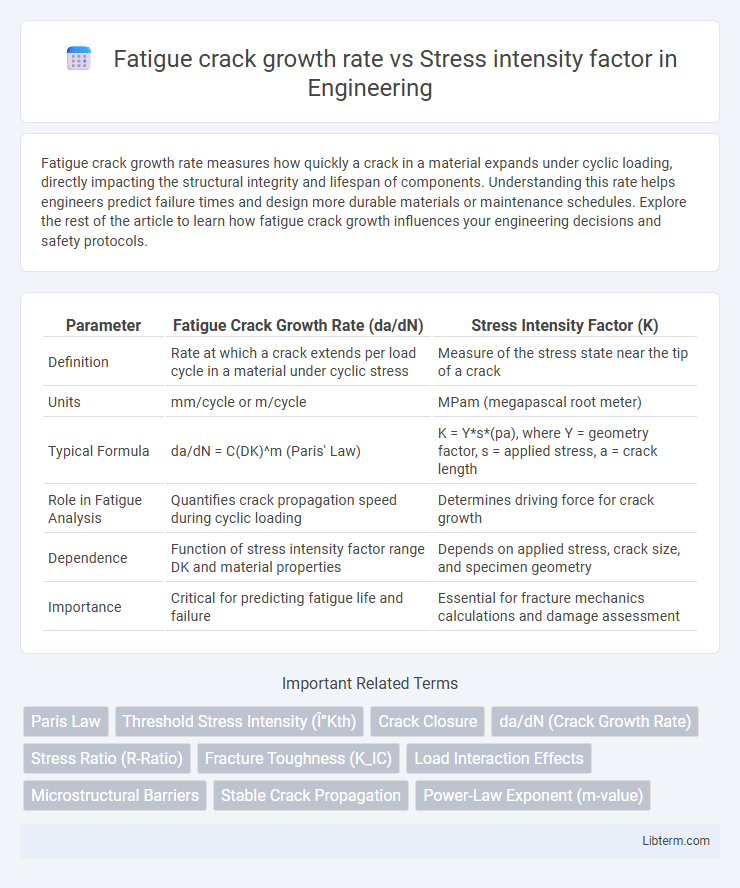

| Parameter | Fatigue Crack Growth Rate (da/dN) | Stress Intensity Factor (K) |

|---|---|---|

| Definition | Rate at which a crack extends per load cycle in a material under cyclic stress | Measure of the stress state near the tip of a crack |

| Units | mm/cycle or m/cycle | MPam (megapascal root meter) |

| Typical Formula | da/dN = C(DK)^m (Paris' Law) | K = Y*s*(pa), where Y = geometry factor, s = applied stress, a = crack length |

| Role in Fatigue Analysis | Quantifies crack propagation speed during cyclic loading | Determines driving force for crack growth |

| Dependence | Function of stress intensity factor range DK and material properties | Depends on applied stress, crack size, and specimen geometry |

| Importance | Critical for predicting fatigue life and failure | Essential for fracture mechanics calculations and damage assessment |

Introduction to Fatigue Crack Growth

Fatigue crack growth rate (da/dN) quantifies crack extension per loading cycle as a function of the stress intensity factor range (DK), reflecting material response under cyclic stress. Paris' law models this relationship, where da/dN = C(DK)^m, with C and m empirically derived constants specific to material and environment. Understanding the interplay between fatigue crack growth rate and stress intensity factor is fundamental for predicting fatigue life and ensuring structural integrity in engineering applications.

Understanding Stress Intensity Factor

The stress intensity factor (K) quantifies the intensity of the stress field near the tip of a crack and is critical in predicting fatigue crack growth rate (da/dN). As K increases, the crack growth rate accelerates due to the amplified stress concentration driving crack propagation. Understanding the relationship between fatigue crack growth rate and the stress intensity factor allows engineers to assess material durability and predict the service life of structural components under cyclic loading.

Relationship Between Fatigue Crack Growth Rate and Stress Intensity Factor

The fatigue crack growth rate (da/dN) exhibits a power-law relationship with the stress intensity factor range (DK), often described by the Paris' law equation da/dN = C(DK)^m, where C and m are material-dependent constants. As the stress intensity factor approaches a threshold value (DK_th), crack growth rate diminishes significantly, indicating crack arrest below this threshold. Beyond this threshold and below the fracture toughness (K_IC), the crack growth rate increases exponentially, reflecting accelerated propagation driven by higher cyclic stress intensity.

Paris Law: Fundamentals and Applications

The fatigue crack growth rate (da/dN) relates directly to the stress intensity factor range (DK) through the Paris Law, expressed as da/dN = C(DK)^m, where C and m are material constants determined experimentally. This empirical relationship captures the intermediate crack growth regime, providing critical insights for predicting structural life and preventing failure in metals. Applications span aerospace, automotive, and civil engineering, where accurate crack growth predictions enhance maintenance planning and safety assessments.

Factors Influencing Fatigue Crack Growth

Fatigue crack growth rate is highly dependent on the range of the stress intensity factor (DK), with higher DK values typically accelerating crack propagation in materials. Material properties such as microstructure, hardness, and fracture toughness significantly influence the sensitivity of fatigue crack growth to stress intensity. Environmental conditions, loading frequency, and the presence of corrosive agents also affect the growth rate by altering crack tip chemistry and mechanical behavior.

Experimental Methods for Measuring Crack Growth

Fatigue crack growth rate (da/dN) is closely correlated with the stress intensity factor range (DK), making precise measurement of crack length and applied load crucial. Experimental methods such as compliance techniques, optical microscopy, and digital image correlation (DIC) enable accurate tracking of crack propagation in materials under cyclic loading. Load-controlled fatigue testing combined with real-time crack length monitoring provides essential data for constructing da/dN versus DK curves critical in fracture mechanics.

Effects of Material Properties on Crack Growth Rate

Fatigue crack growth rate is significantly influenced by material properties such as fracture toughness, yield strength, and microstructural characteristics, which affect the stress intensity factor (K) threshold and crack propagation behavior. Materials with higher fracture toughness typically exhibit lower crack growth rates for a given stress intensity factor range (DK) due to their ability to better resist crack tip plasticity and microvoid coalescence. The interaction between the stress intensity factor range and intrinsic material characteristics defines the fatigue crack propagation threshold, dictating durability and service life predictions for structural components.

Environmental and Loading Conditions

Fatigue crack growth rate (da/dN) is highly sensitive to stress intensity factor range (DK), with environmental factors such as humidity, temperature, and corrosive media accelerating crack propagation by altering crack tip chemistry and oxide formation. Loading conditions including frequency, stress ratio (R), and waveform significantly influence crack growth dynamics; higher frequencies often reduce environmental effects whereas increasing R-ratio typically enhances crack opening, promoting faster growth. Experimental data correlates elevated temperatures and corrosive environments with increased crack growth rates at given DK, highlighting the need for comprehensive evaluation in material durability assessments.

Case Studies: Fatigue Crack Growth in Engineering Materials

Fatigue crack growth rate (da/dN) shows a significant dependency on the stress intensity factor range (DK), with case studies on engineering materials like aluminum alloys and steels demonstrating critical threshold values below which crack propagation ceases. Experimental data from these materials reveal Paris' law constants unique to each alloy, highlighting microstructural influences such as grain size and precipitate distribution on crack growth kinetics. Understanding the correlation between da/dN and DK enables precise life prediction of components subjected to cyclic loading in aerospace and automotive industries.

Future Trends in Crack Growth Prediction and Control

Advancements in fatigue crack growth rate modeling increasingly leverage machine learning algorithms and real-time sensor data to improve the accuracy of stress intensity factor range predictions. Integration of multiscale material characterization and predictive analytics enables proactive crack control strategies, significantly reducing maintenance costs and enhancing structural safety. Future trends emphasize adaptive monitoring systems and AI-driven simulations for dynamic crack growth behavior under complex loading conditions.

Fatigue crack growth rate Infographic

libterm.com

libterm.com