Heat exchanger effectiveness measures the efficiency of heat transfer between two fluids, directly impacting your system's performance and energy usage. The heat transfer area plays a crucial role in determining the rate of heat exchange, where a larger surface area typically enhances thermal transfer. Explore this article to understand how optimizing these factors can improve your heat exchanger design and operation.

Table of Comparison

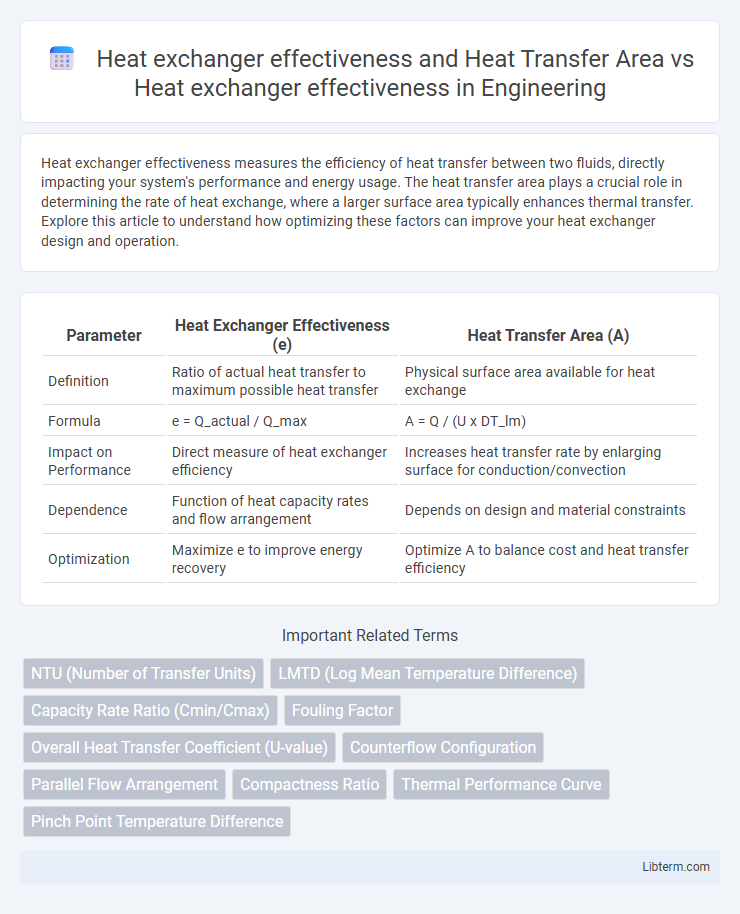

| Parameter | Heat Exchanger Effectiveness (e) | Heat Transfer Area (A) |

|---|---|---|

| Definition | Ratio of actual heat transfer to maximum possible heat transfer | Physical surface area available for heat exchange |

| Formula | e = Q_actual / Q_max | A = Q / (U x DT_lm) |

| Impact on Performance | Direct measure of heat exchanger efficiency | Increases heat transfer rate by enlarging surface for conduction/convection |

| Dependence | Function of heat capacity rates and flow arrangement | Depends on design and material constraints |

| Optimization | Maximize e to improve energy recovery | Optimize A to balance cost and heat transfer efficiency |

Understanding Heat Exchanger Effectiveness

Heat exchanger effectiveness quantifies the efficiency of heat transfer between hot and cold fluids, defined as the ratio of actual heat transfer to the maximum possible heat transfer under ideal conditions. Increasing the heat transfer area enhances the effectiveness by providing more surface for thermal exchange, thus reducing temperature differences between fluids. Optimizing effectiveness involves balancing heat transfer area with flow rates and fluid properties to achieve desired thermal performance without excessive cost or size.

Key Factors Influencing Effectiveness in Heat Exchangers

Heat exchanger effectiveness is primarily influenced by the heat transfer area, flow arrangement, and temperature difference between fluids, where a larger heat transfer area generally increases effectiveness by providing more surface for thermal exchange. Key factors such as fluid flow rate, thermal conductivity of the exchanger material, and the specific heat capacities of the fluids directly impact the heat exchanger effectiveness by affecting the rate and amount of heat transferred. Optimizing these parameters, along with minimizing fouling and pressure drops, ensures maximum heat exchanger performance and energy efficiency.

Types of Heat Exchangers and Their Efficiency

Shell and tube, plate, and finned tube heat exchangers exhibit varying heat exchanger effectiveness depending on their design and application. Heat exchanger effectiveness is influenced by the heat transfer area, where increased surface area enhances thermal performance and overall efficiency. Among these types, plate heat exchangers typically achieve higher effectiveness due to their large heat transfer area and compact design, making them efficient for both liquid-to-liquid and liquid-to-gas heat exchange processes.

Heat Transfer Area: Definition and Importance

Heat transfer area is the surface through which heat flows in a heat exchanger, directly impacting its effectiveness by facilitating thermal energy exchange between fluids. An increased heat transfer area enhances heat exchanger effectiveness by allowing more heat to be transferred, improving overall performance and energy efficiency. Optimizing the heat transfer area is crucial for designing compact, cost-effective heat exchangers with high thermal conductivity and minimal pressure drops.

Relationship Between Heat Transfer Area and Effectiveness

Heat exchanger effectiveness measures the efficiency of heat transfer relative to the maximum possible heat transfer, which depends directly on the heat transfer area. Increasing the heat transfer area enhances the surface available for heat exchange, thereby raising the effectiveness by facilitating more thermal energy transfer between fluids. Optimal design balances the heat transfer area with flow rates and temperature differences to maximize effectiveness without excessive material costs.

Methods to Increase Heat Exchanger Effectiveness

Increasing heat exchanger effectiveness relies on enhancing heat transfer rates through optimized design and operational methods. Techniques such as increasing the heat transfer area by using extended surfaces like fins, employing multi-pass configurations to improve fluid contact, and selecting high-efficiency materials with superior thermal conductivity significantly improve effectiveness. Additionally, maximizing turbulence with inserts, optimizing flow arrangement (counterflow over parallel flow), and maintaining appropriate temperature differences between hot and cold streams are key strategies for improving heat exchanger performance.

Impact of Heat Transfer Area on Thermodynamic Performance

Heat exchanger effectiveness directly depends on the heat transfer area as larger surfaces facilitate greater thermal energy exchange, increasing the overall efficiency of the device. An increased heat transfer area reduces temperature differences between fluids, optimizing heat transfer rates and improving thermodynamic performance by minimizing entropy generation. The correlation between heat transfer area and effectiveness plays a critical role in the design of compact and efficient heat exchangers for industrial applications.

Design Considerations: Area vs. Effectiveness Optimization

Heat exchanger effectiveness directly influences the required heat transfer area, where a higher effectiveness typically demands an increased surface area to achieve desired thermal performance. Optimizing design involves balancing the heat transfer area with cost and space constraints while maximizing thermal efficiency through careful selection of materials, flow arrangements, and operating conditions. Advanced computational methods and performance correlations help predict the effectiveness-area relationship, enabling engineers to optimize design parameters for cost-effective and efficient heat exchanger operation.

Practical Examples: Effectiveness Variation with Area

Heat exchanger effectiveness increases as the heat transfer area expands, enhancing the rate at which heat is exchanged between fluids. In practical applications such as shell-and-tube or plate heat exchangers, larger surface areas allow closer approach temperatures, improving thermal performance. For example, doubling the area in a shell-and-tube heat exchanger can boost effectiveness from 0.65 to 0.85, optimizing energy recovery in industrial processes.

Best Practices for Maximizing Heat Exchanger Performance

Maximizing heat exchanger effectiveness relies on optimizing heat transfer area and flow arrangement to enhance thermal contact and minimize temperature differences. Implementing counterflow configurations and increasing surface area through finned or corrugated surfaces significantly improve heat transfer rates. Regular maintenance to prevent fouling and selecting materials with high thermal conductivity are best practices that sustain peak performance and energy efficiency.

Heat exchanger effectiveness and Heat Transfer Area Infographic

libterm.com

libterm.com